Halt anti-scattering mechanism and method for broken wires and bond wires

A line detection and anti-scattering technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems affecting the normal production of adjacent lines, sticking thread ends, and fast shaking, etc., and achieves ingenious structural design and fast speed. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

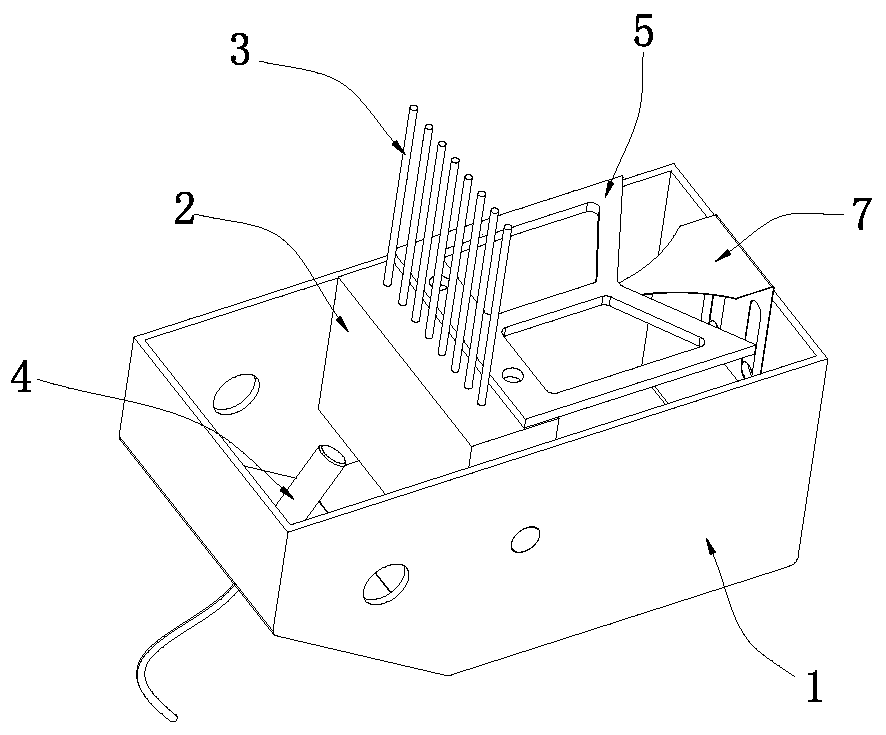

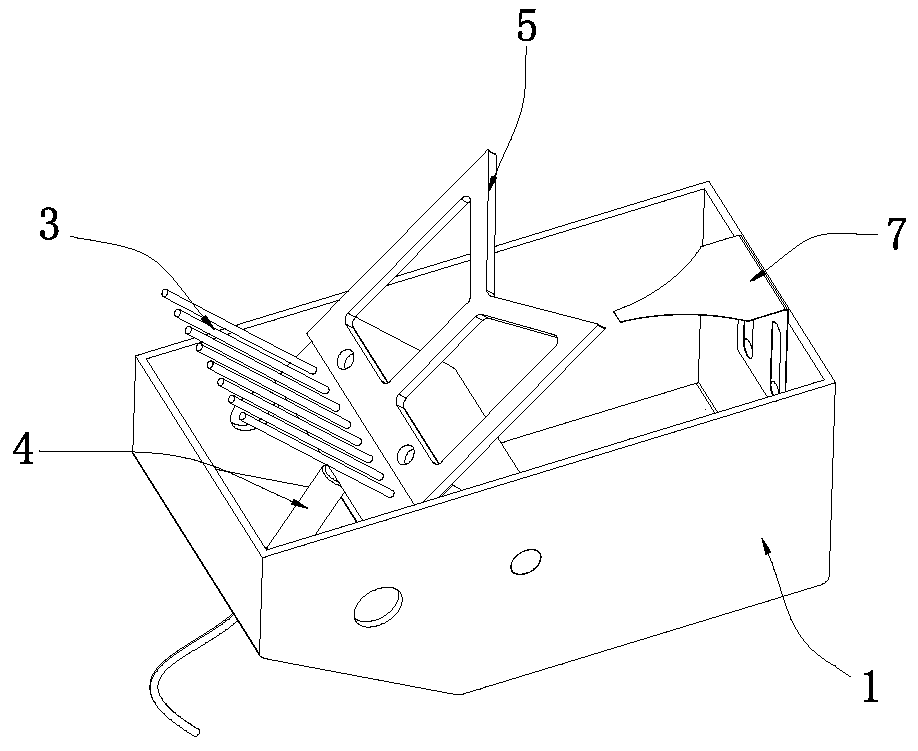

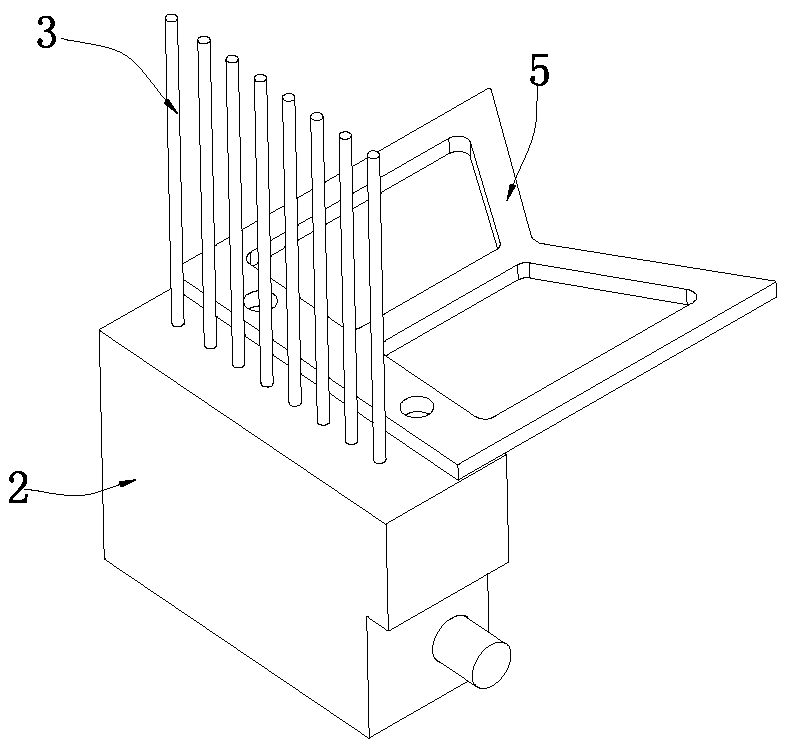

[0031] Example: see Figure 1 to Figure 8 , a wire breaking and sticking detection shutdown anti-scattering mechanism provided in an embodiment of the present invention, which includes a fixed seat 1 , a swivel seat 2 , a wire retaining lever 3 , a detection switch 4 and a wire harness 5 .

[0032] The swivel base 2 is rotatably installed on the fixed base 1 . Specifically, the lower part of the swivel base 2 is provided with a shaft hole through which a rotating shaft 21 is disposed on the fixed base 1 at the end. It is also possible to add a copper sleeve or a bearing in the shaft hole, which can further improve the smoothness of rotation and prolong the service life.

[0033] A plurality of wire retaining rods 3 are arranged side by side on the turntable 2 at intervals, and a wire passing groove 6 for the wire to pass is formed between two adjacent wire retaining rods 3; The surface is provided with a socket adapted to the wire retaining rod 3, and the lower end of the wir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com