Automatic control method, control system and harvester for continuously variable speed of drum

An automatic control system and continuously variable speed technology, applied in the field of harvesters, can solve the problems of drum blockage, large cleaning loss rate, and high grain breakage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

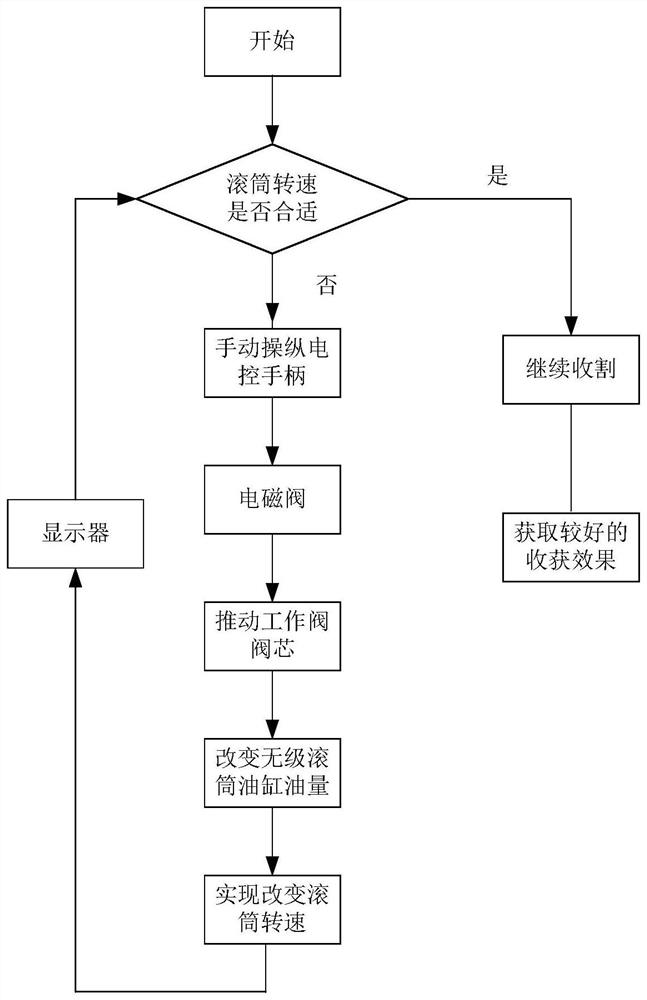

[0035] Such as figure 1 As shown, in the prior art, the adjustment of the rotating speed of the drum is carried out manually. Specifically, the driver judges according to the rotating speed displayed on the display. Power on, push the spool of the working valve to move, make the stepless drum oil cylinder fill or discharge oil, and change the speed of the drum by controlling the stroke of the stepless drum oil cylinder. In this manual control method, the driver adjusts the electric control handle through the speed of the display during the harvesting process, which belongs to an open-loop system, and the speed cannot be adjusted automatically.

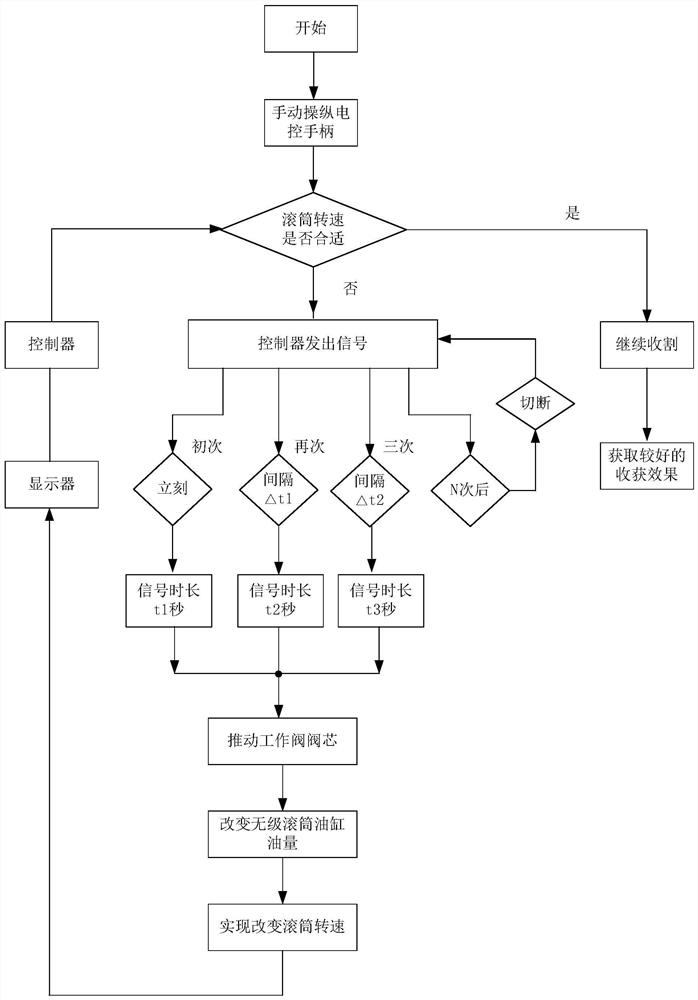

[0036] Such as figure 2 As shown, the present invention relates to an automatic control method for a continuously ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com