Treatment method and apparatus for condensable particulate matter and moisture in flue gas and coal-fired flue gas treatment system

A treatment device and particulate matter technology, which is applied in the field of flue gas purification, can solve the problems of lack of control means and methods for condensable particulate matter, wet smoke and rain, etc., and achieve the effect of removing condensable particulate matter and moisture, eliminating gypsum rain, and good condensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail through the following embodiments and in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

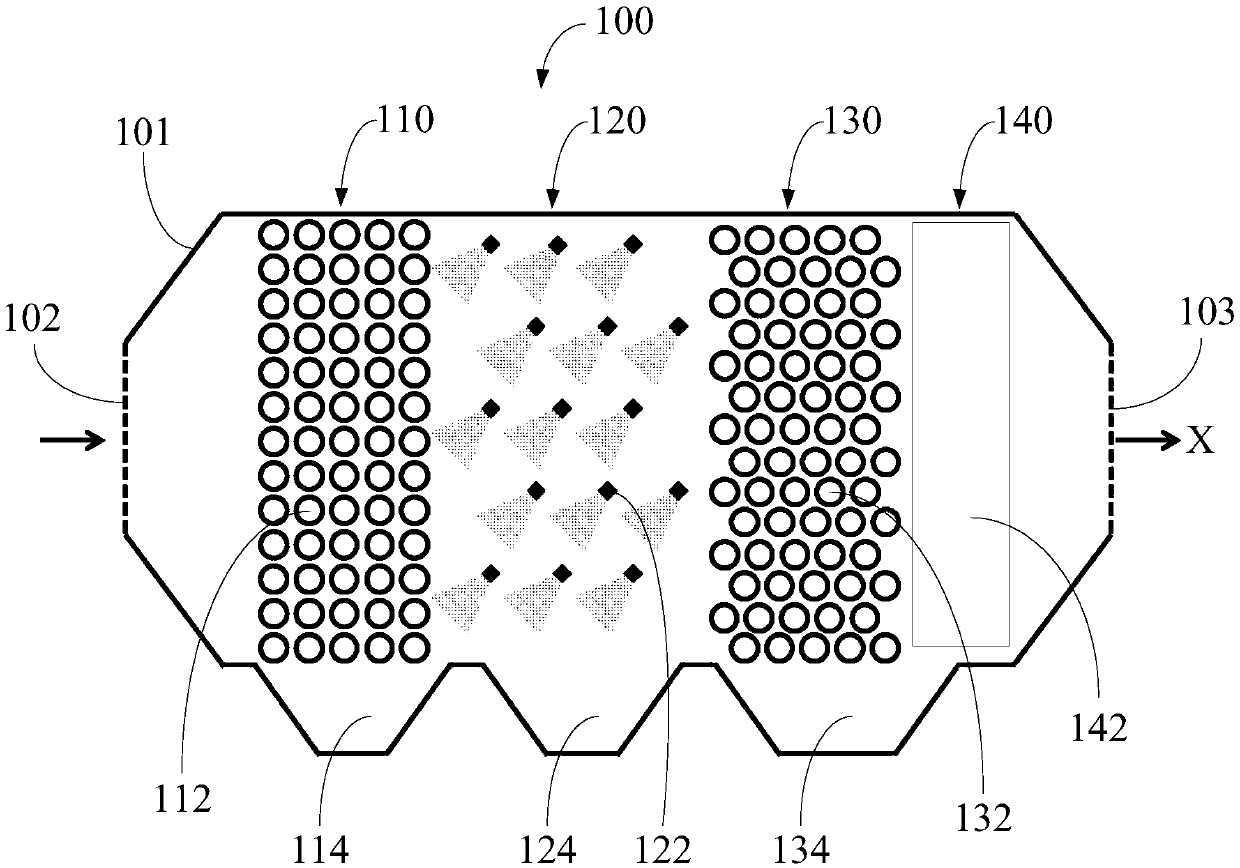

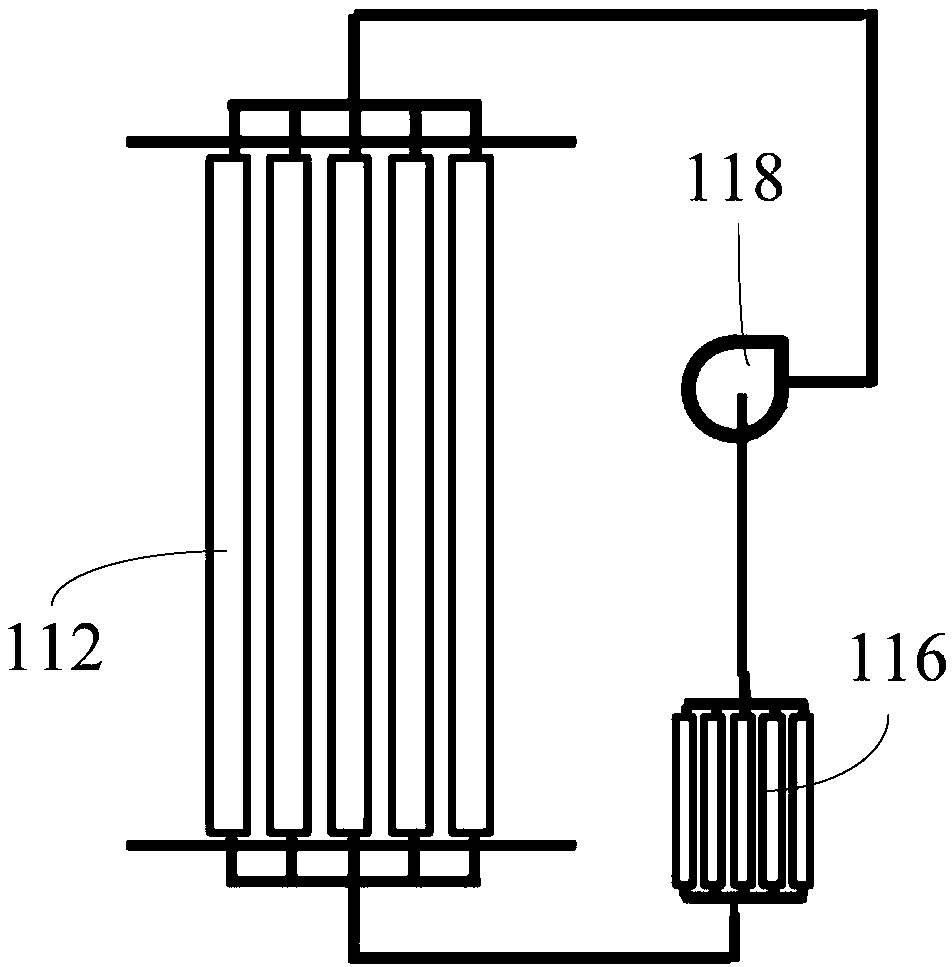

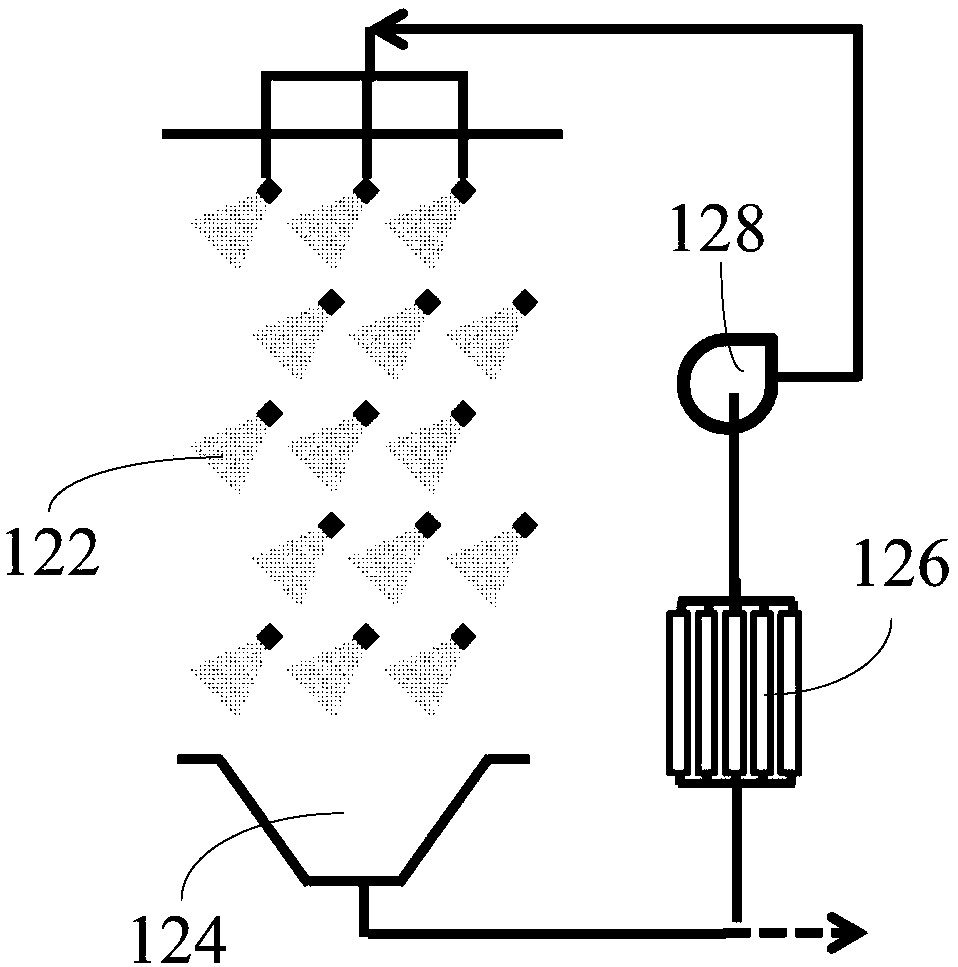

[0026] see figure 1 , the present invention provides a treatment device 100 for condensable particulate matter and moisture in flue gas, and the treatment device 100 has a casing 101 . A first zone 110 , a second zone 120 and a third zone 130 are sequentially arranged in the housing 101 along the horizontal direction X. A first tube bundle heat exchanger 112 and a first liquid collection tank 114 located below the first tube bundle heat exchanger 112 are arranged in the first zone 110 . The second zone 120 is provided with a spraying device 122 and a second liquid collection tank ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com