Bus side wall framework assembly structure

A side frame and assembly structure technology, which is applied to the superstructure, superstructure sub-assembly, vehicle parts, etc., can solve the problems of occupying the upper space of the bus, the limited strength of the upper structure of the bus, and unfavorable installation of other decorative parts. Achieve the effect of ensuring the living space, enhancing the bending rigidity and deformation resistance, and reducing the amount of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

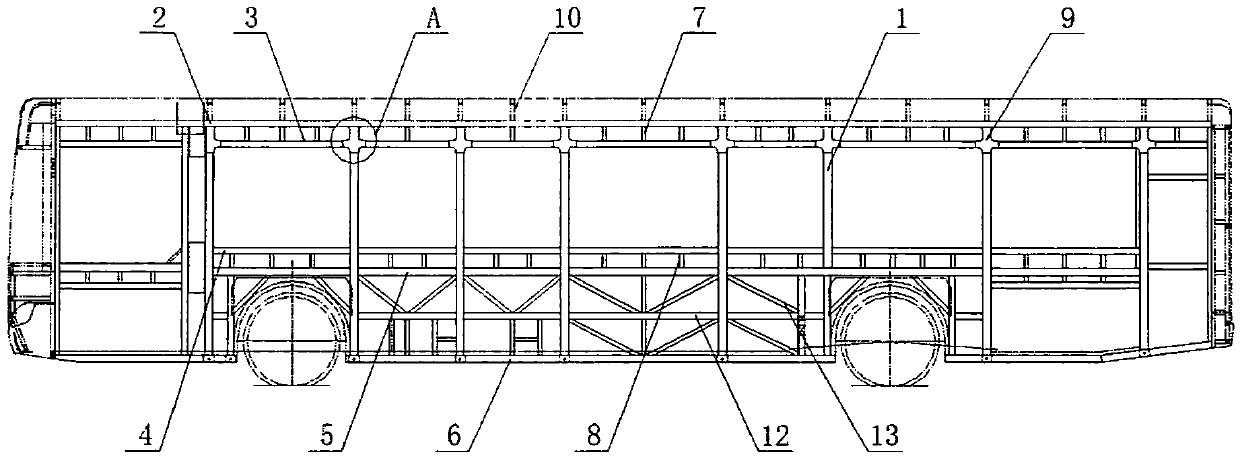

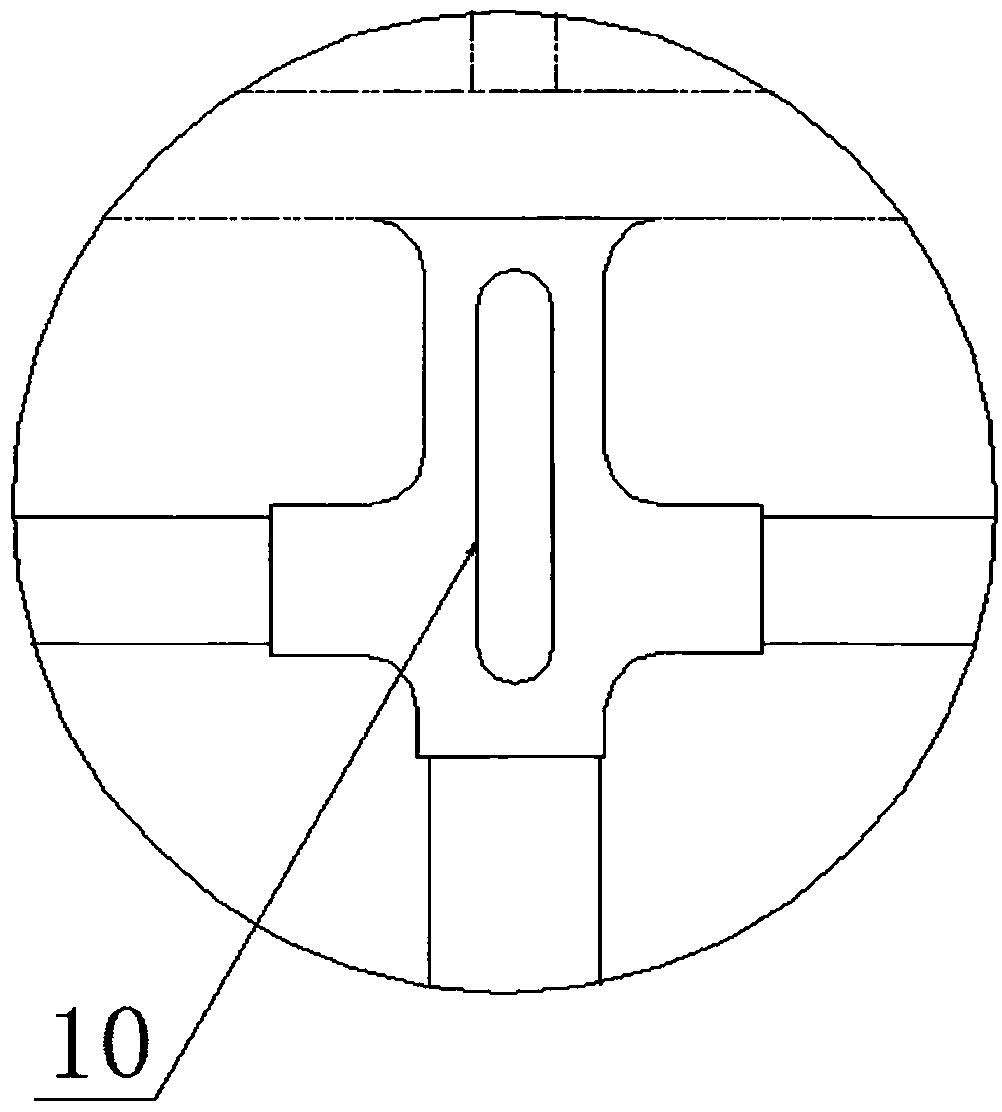

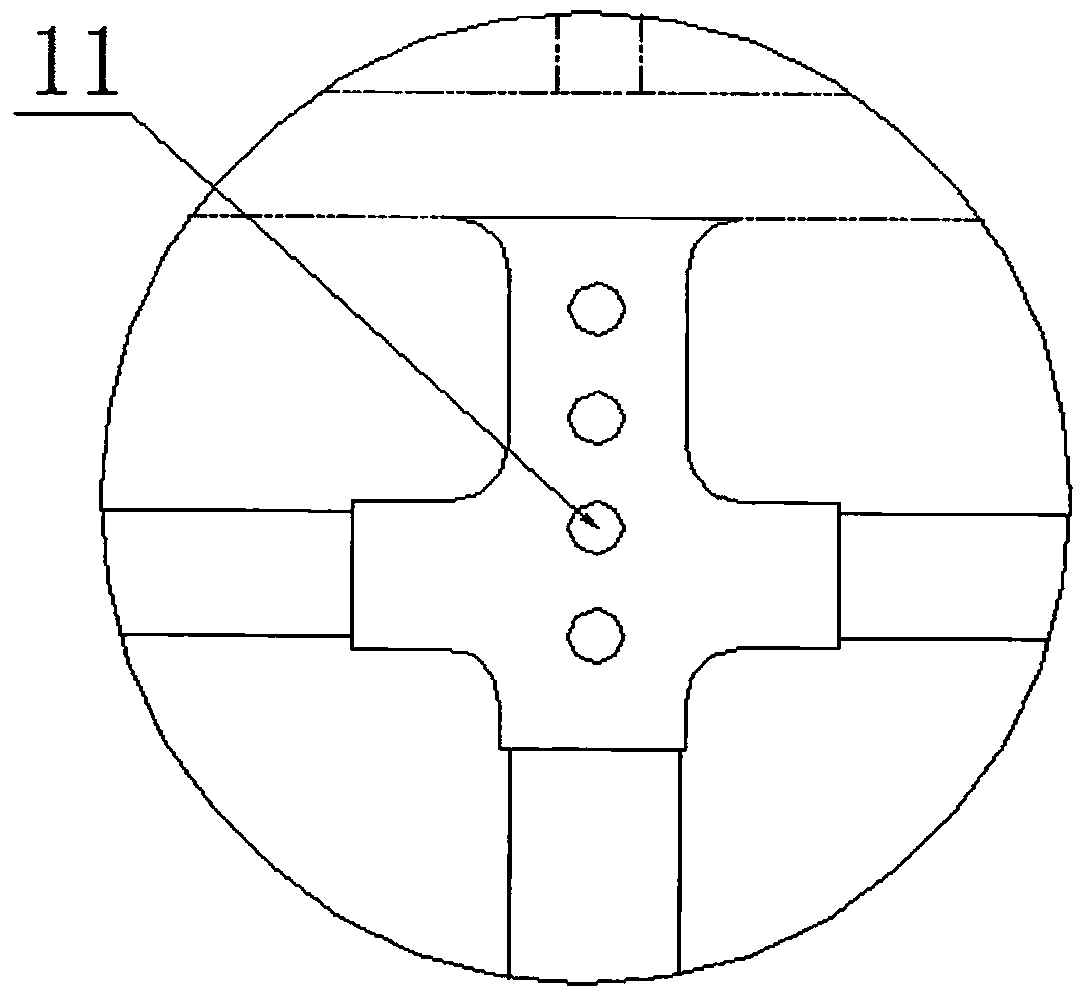

[0032] Such as Figure 1 ~ Figure 3 As shown, a passenger car side wall frame assembly structure in this embodiment includes a plurality of main columns 1 arranged in parallel from front to back, and the plurality of main columns 1 are sequentially provided with roof vertical columns from top to bottom. Beam 2, side window upper stringer 3, side window lower stringer 4, hatch upper stringer 5 and hatch door lower stringer 6, a plurality of roof stringers 2 and side window upper stringers 3 are provided The first support column 7, the second support column 8 is arranged between the side window lower stringer 4 and the cabin door upper stringer 5, and a sword handle is arranged at the connection position between the side window upper stringer 3 and the main column 1 skeleton9;

[0033] The sword hilt skeleton 9 is cross-shaped, and the cross-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com