An automatic rotating uninterrupted fast brick stacking machine

An automatic rotating and stacking brick machine technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of equipment use cost and maintenance cost increase, accelerated wear of moving parts, and low efficiency of continuous brick picking, so as to reduce equipment maintenance Effects of cost reduction, simplification of action, and reduction of reset time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

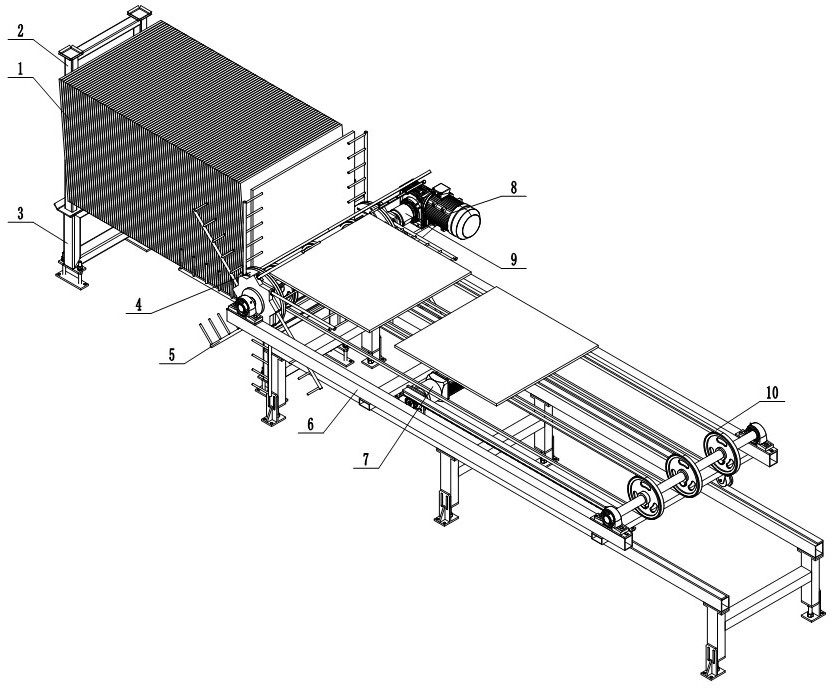

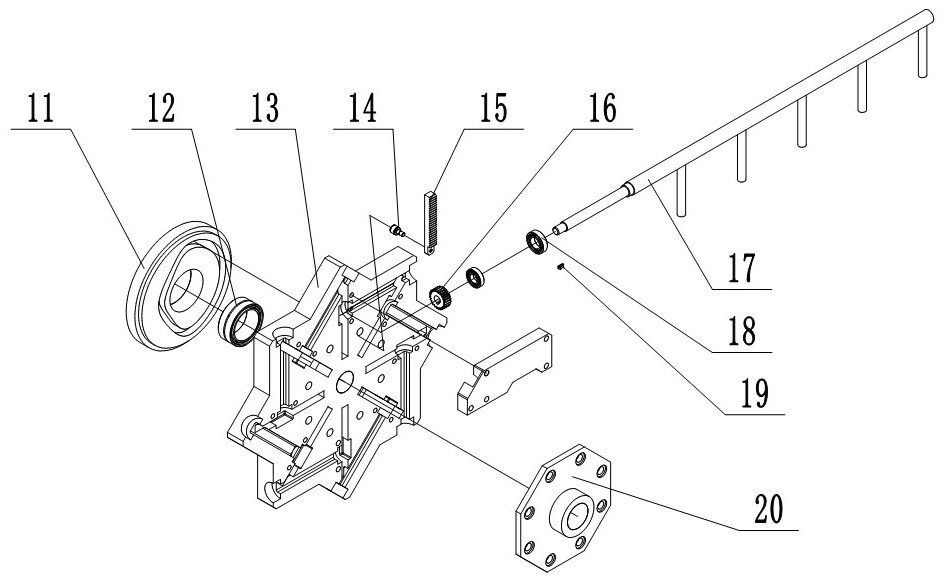

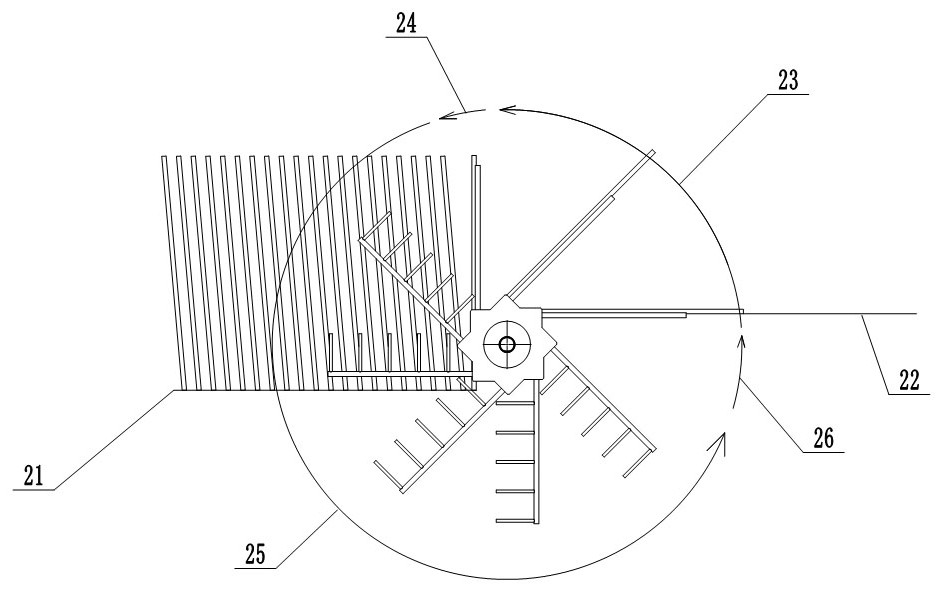

[0025] Such as figure 1 The three-to-eight-leaf windmill-type high-speed brick-discharging device shown includes a brick storage rack 2, a brick storage rack support frame 3, an automatic cam-driven brick-picking arm circular obstacle avoidance reset device 4, and angular displacement control of brick adobe rotation and fall buffering and anti-collision Device 5, stacking brick displacement conveying control frame 6, rack and pinion servo drive device 7, rotating drive device 8, conveyor belt 10; brick stacking displacement conveying control frame 6 is fixed on the ground, and the front section of brick stacking displacement conveying control frame 6 is provided The rotating shaft 9, the brick storage rack support frame 3 is fixed on the side of the stacking brick displacement conveying control frame 6 provided with the rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com