An automatic silk reeling machine exploration perception mechanism

A silk reeling machine and automatic technology, applied in the field of automatic silk reeling machine exploration and perception mechanism, can solve the problems of mechanical signal delay working state and parameter feedback, single exploration cycle, not in time, etc., to reduce the length of falling filaments, The effect of improving raw silk quality and reducing lag time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

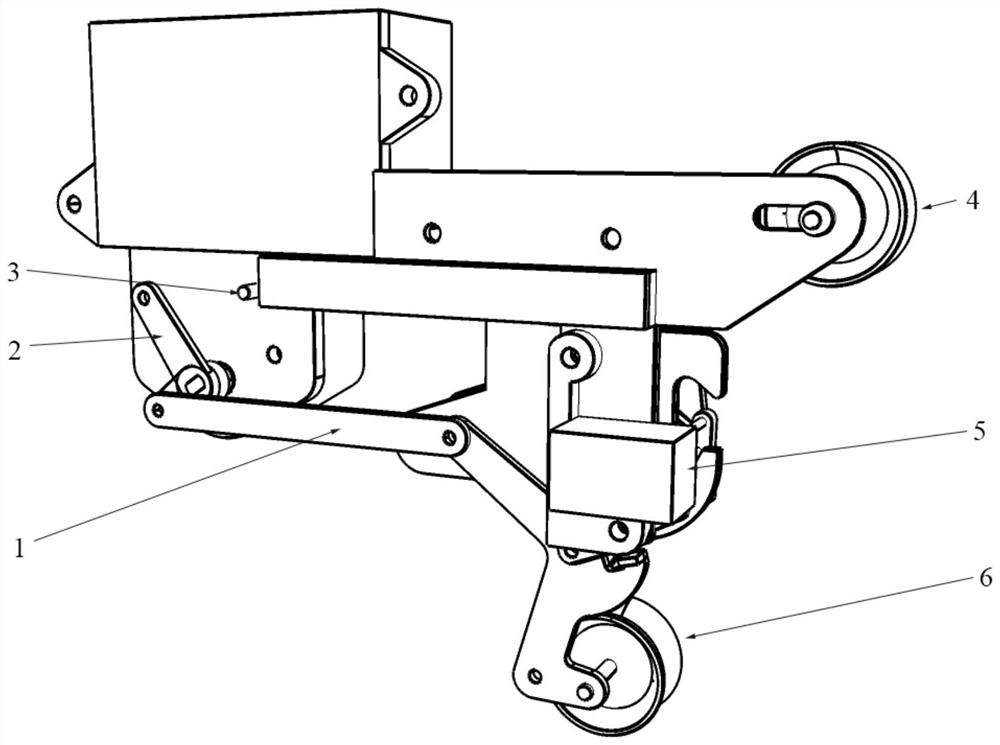

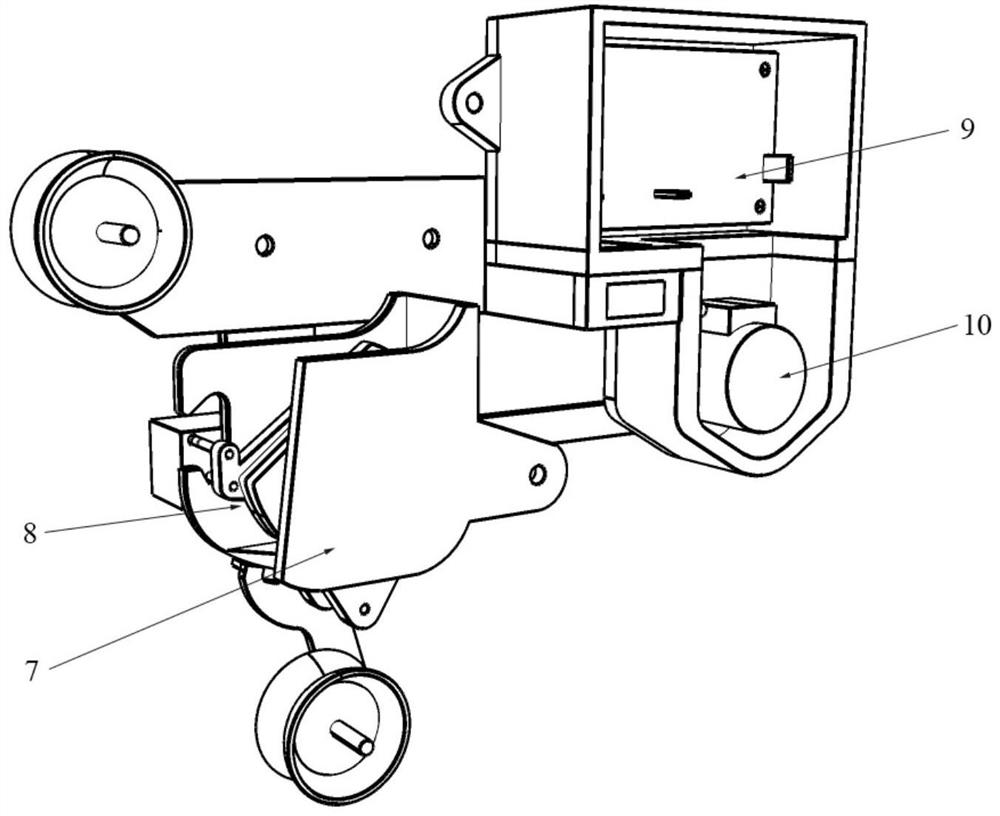

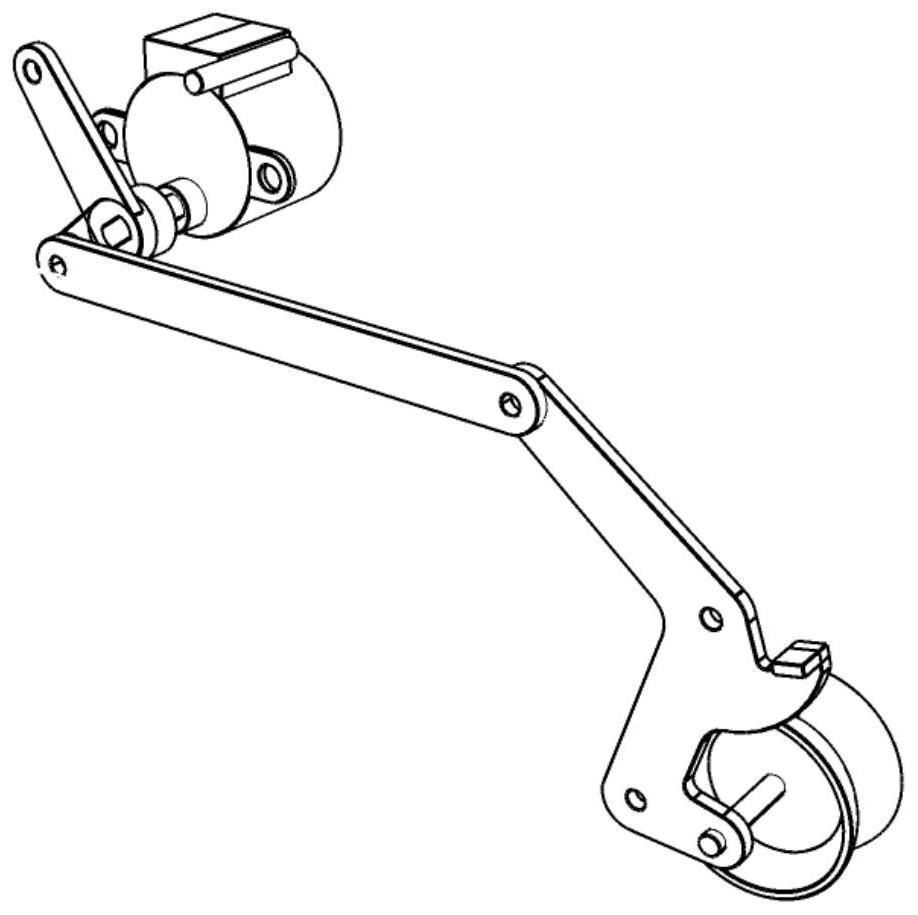

[0023] see figure 1 , figure 2 , image 3 , the present invention includes a relatively fixed first bracket and a second bracket, a crank rocker mechanism 1, an induction arm 2, a first Hall sensor 3, an upper positioning drum 4, a second Hall sensor 5, an exploration drum 6, Fineness sensor seat 7, short lever gauge fixed fiber sensor 8, controller 9 and stepper motor 10. The invention uses a stepper motor as the power source of the exploration movement, and uses a Hall sensor to convert the mechanical signal of the short-lever-gauge fixed fiber sensor into an electrical signal, thereby completing the exploration and perception of the raw silk fineness, and the raw silk fineness signal. deal with. In the specific embodiment of the present invention, the controller can adopt STC12C2052AD single-chip microcomputer; the stepper motor model is 28BYJ48, the step angle is 5.625°, and the reduction ratio is 1:16; the stepper motor driver is L293DD; the Hall sensor is A3144EUA. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com