High temperature and high pressure jig dyeing device for cotton cloth production and processing

A high temperature and high pressure, cotton technology, applied in textile processing machine accessories, textile material processing, textile material processing equipment configuration, etc. problems, to achieve the effect of facilitating the jigging operation, facilitating the jigging effect, and improving the jigging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

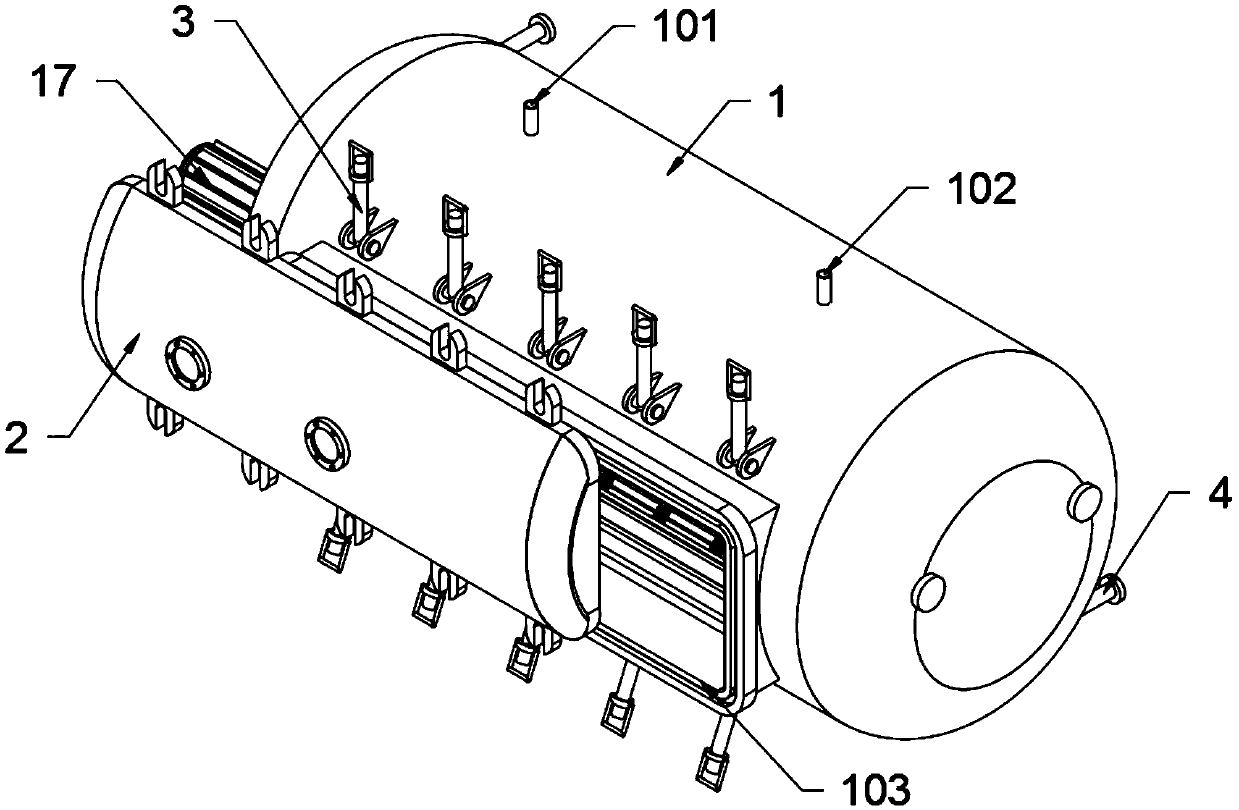

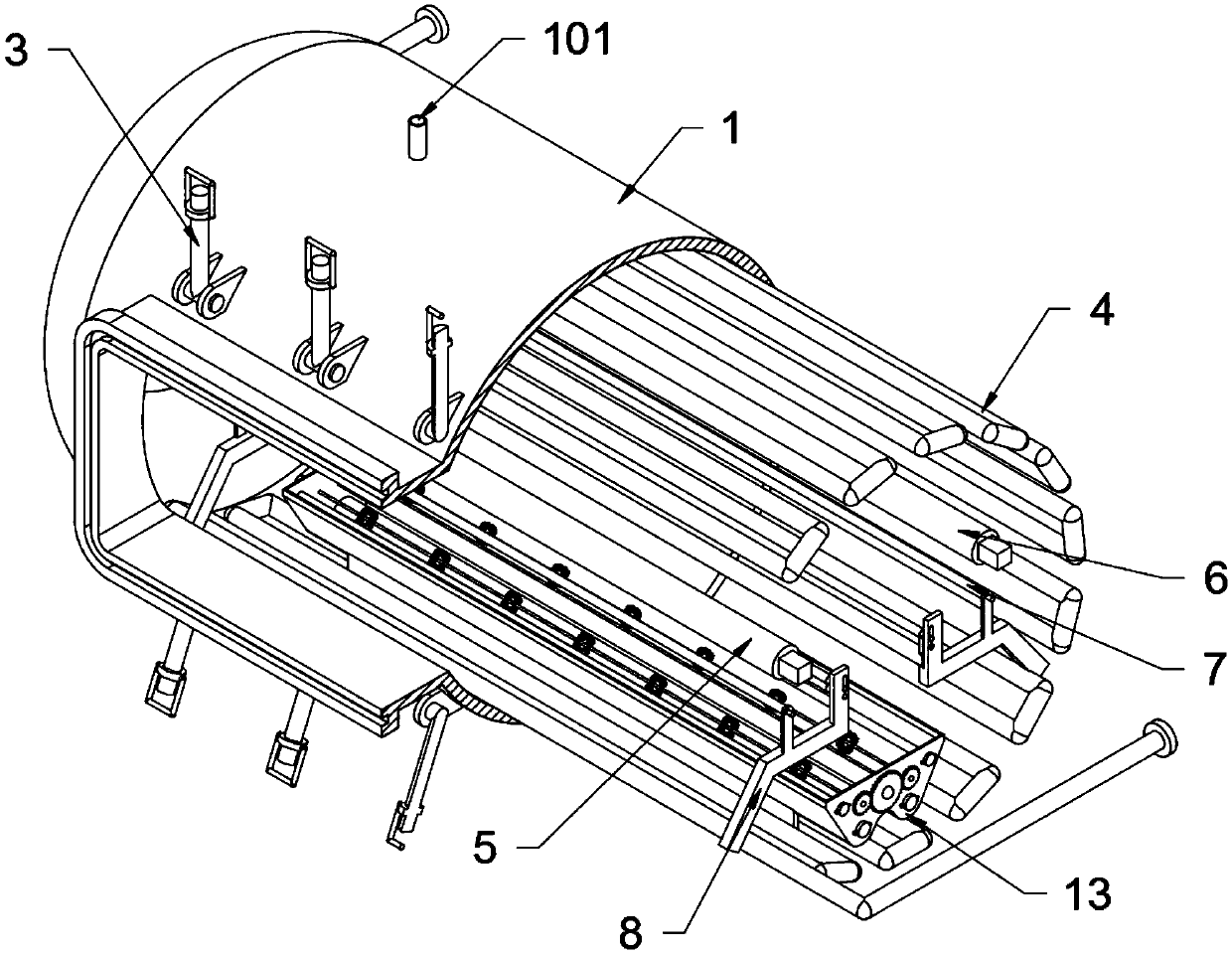

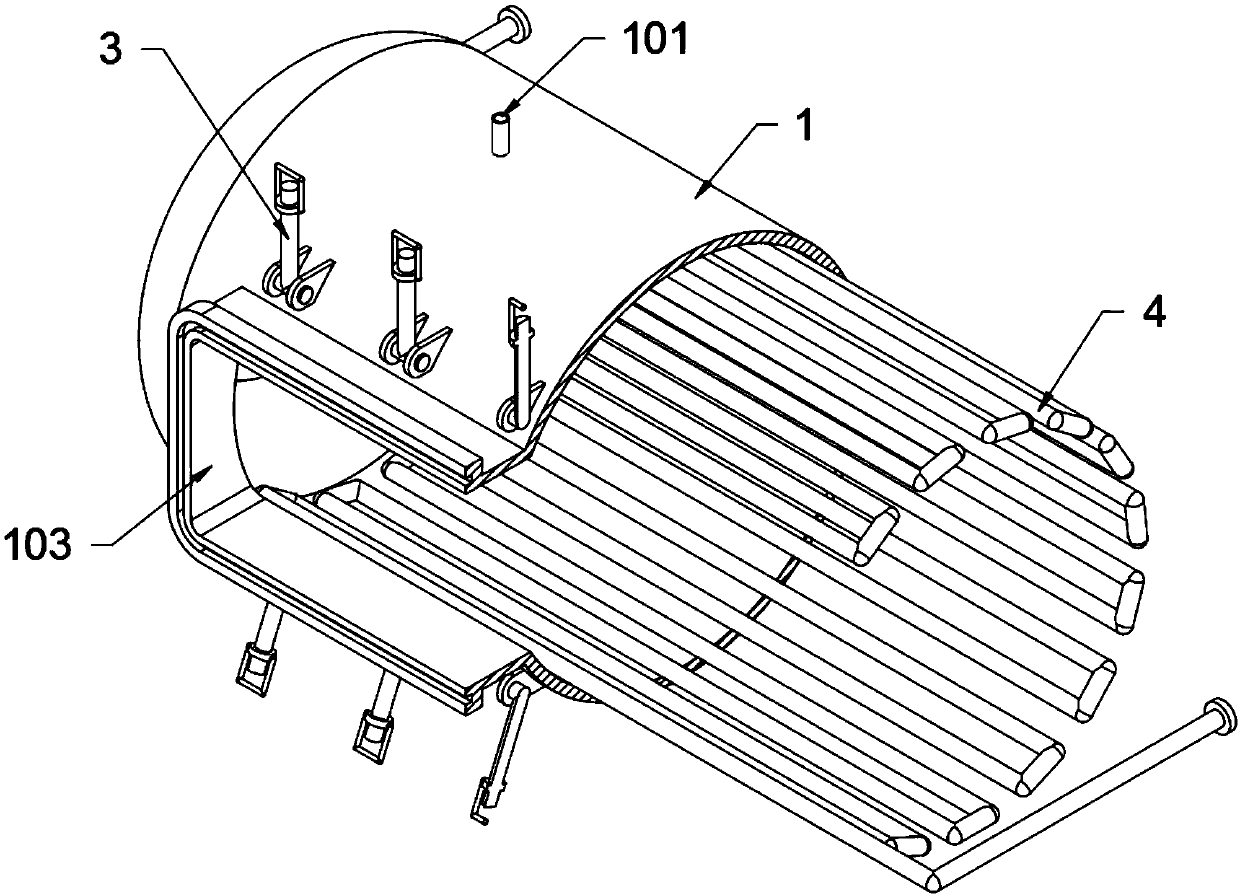

[0038] as attached figure 1 to attach Figure 13 Shown:

[0039]The invention provides a high-temperature and high-pressure dyeing device for cotton cloth production and processing, which includes a cavity 1, a pressure hole 101, a decompression hole 102, a material port 103, a sealing cover 2, a sealing bolt 3, a steam heating tube 4, and an active cloth rolling Roller 5, driven cloth rolling roller 6, reversing roller 7, support block 8, downhole 801, upper squeeze roller 9, lower squeeze roller 10, pull-down collar 11, tension spring 12, dye solution tank 13, dyeing Roller 14, transmission gear 15, stirring shaft 16, stirring blade 1601 and drive motor 17; The top of described cavity 1 is provided with a pressurizing hole 101 and a decompression hole 102 respectively, and pressurizing hole 101 passes high-pressure pipe and The external pressurized equipment is connected; the sealing cover 2 is fixed on the material port 103 at the front end of the cavity 1 through ten sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com