Pipe gallery construction method

A construction method and technology of pipe gallery, which is applied in the field of pipe gallery construction and underground pipe gallery construction, can solve the problems of affecting construction progress and construction efficiency, destroying the balance of soil stress, and prone to soil collapse, so as to avoid soil collapse , reduce the frequency of use, and facilitate construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

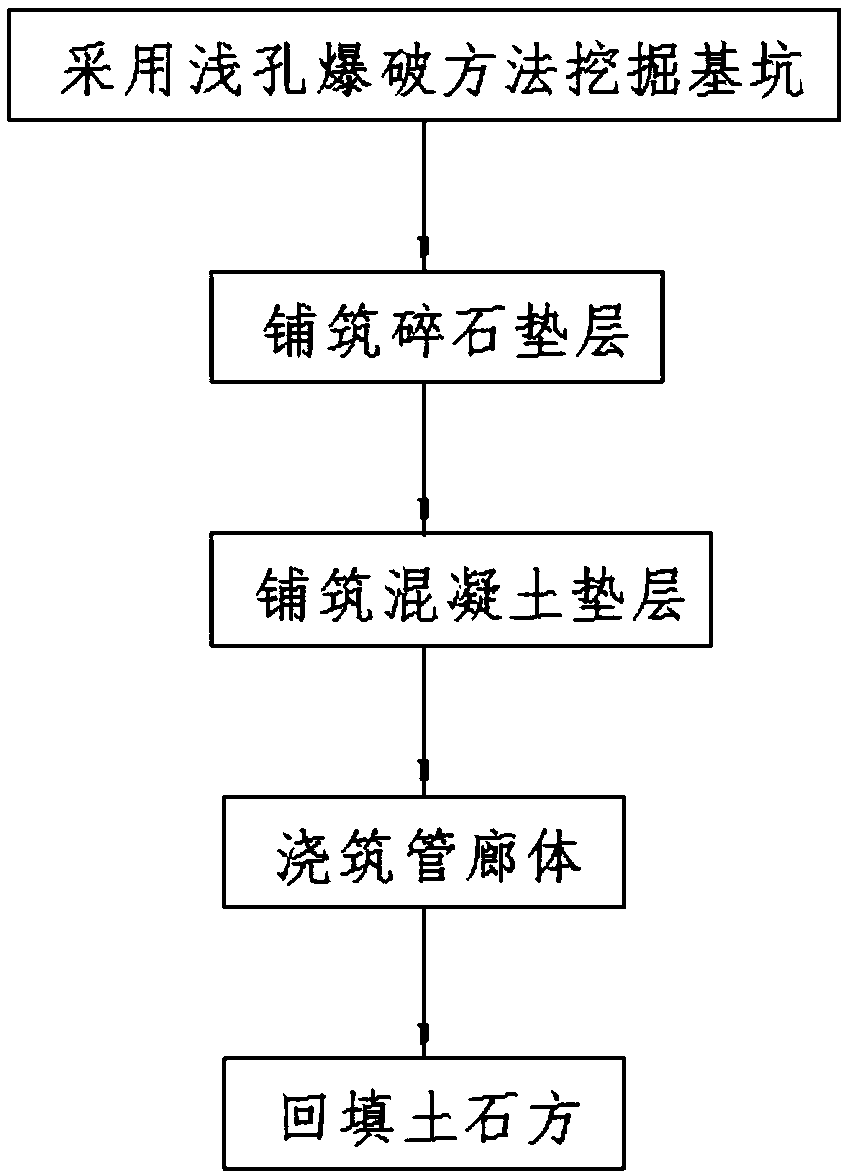

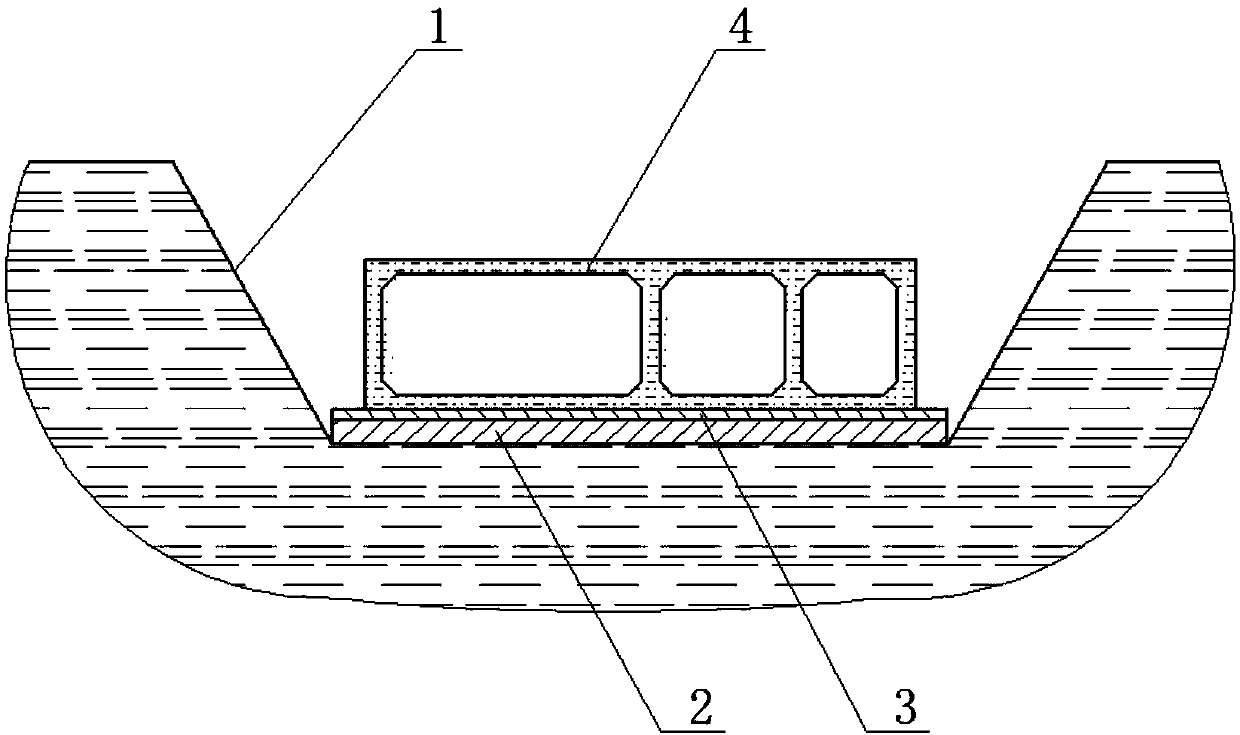

[0029] The invention provides a pipe gallery construction method, such as figure 1 , figure 2 shown, including the following steps:

[0030] Step 1: Excavate the foundation pit 1: Use the shallow hole blasting method to blast the earth and rock on the ground layer by layer according to the direction from top to bottom to loosen the earth and rock on the ground, then use an excavator to remove the loose earth and rock, and excavate on the ground Exit the foundation pit 1, and use the crusher to trim the bottom wall and side wall of the foundation pit 1; further, before step 2, after the foundation pit 1 is excavated and formed, it is advisable to dig a plurality of water collection wells in the vicinity of the foundation pit 1, After the foundation pit 1 is excavated and form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com