Capillary throttling structure for liquid helium temperature zone

A capillary, temperature zone technology, applied in refrigeration and liquefaction, fluid circulation arrangement, mechanical equipment, etc., can solve the problems of poor throttling effect, affecting the throttling refrigeration effect, and reducing the pressure drop at both ends of the capillary, so as to achieve assembly Convenient, export-smooth finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solutions of the embodiments of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

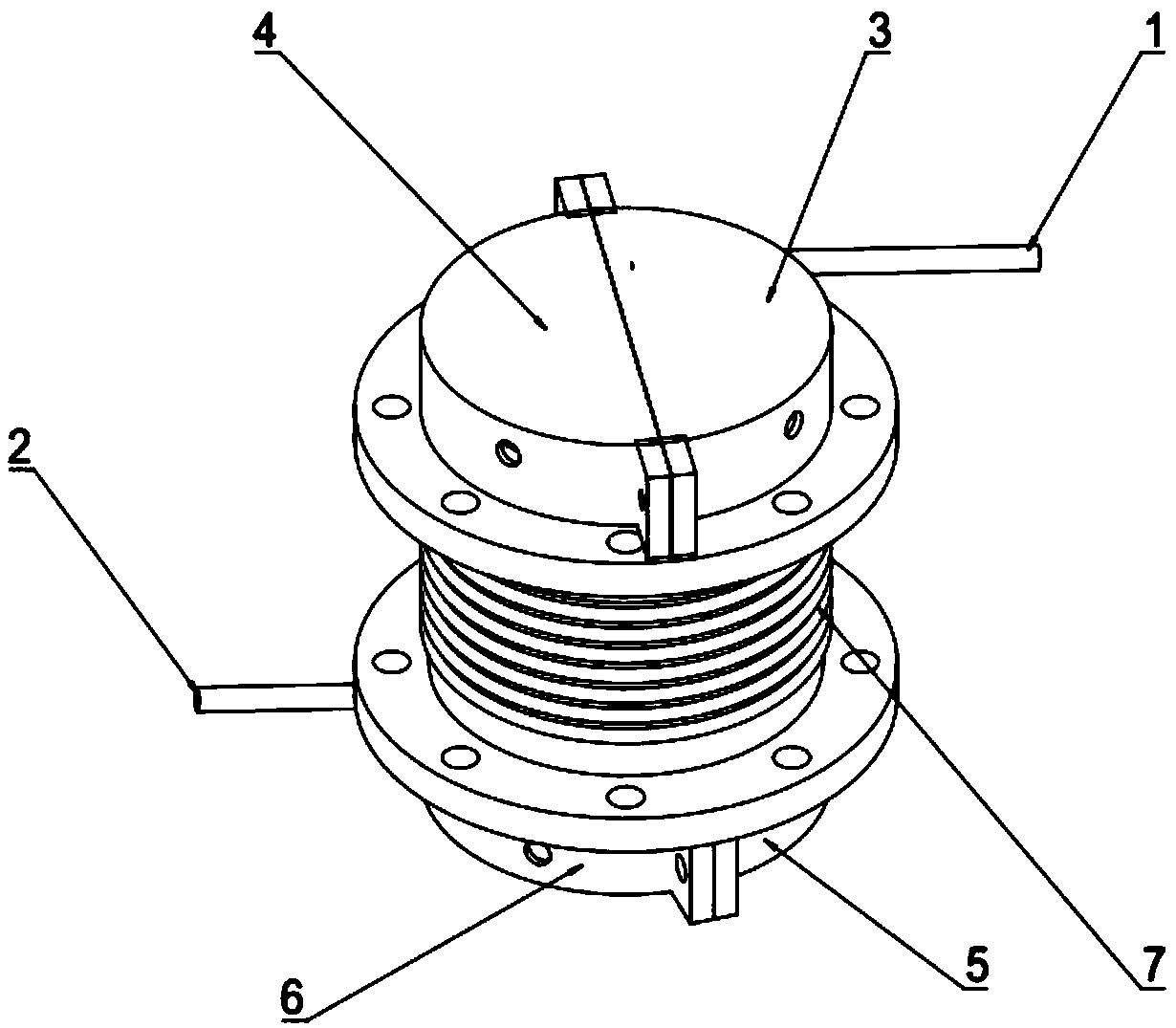

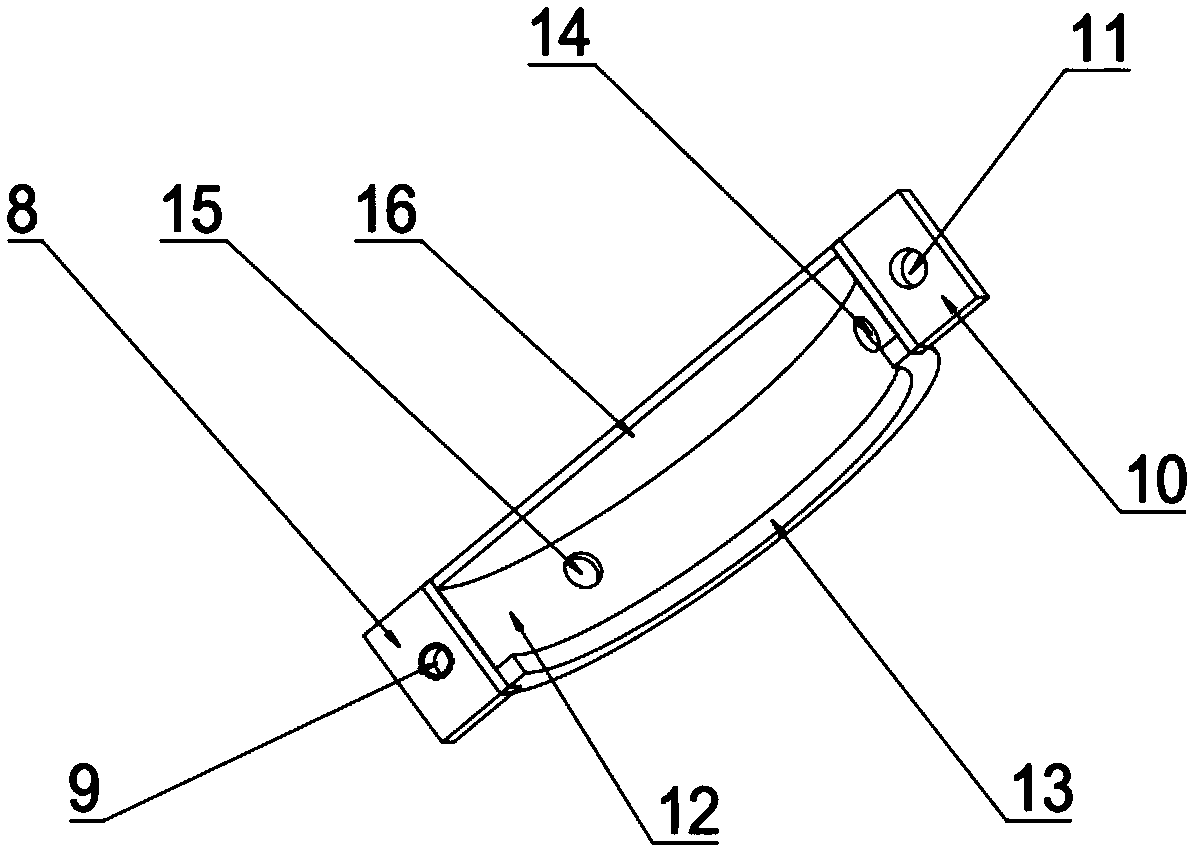

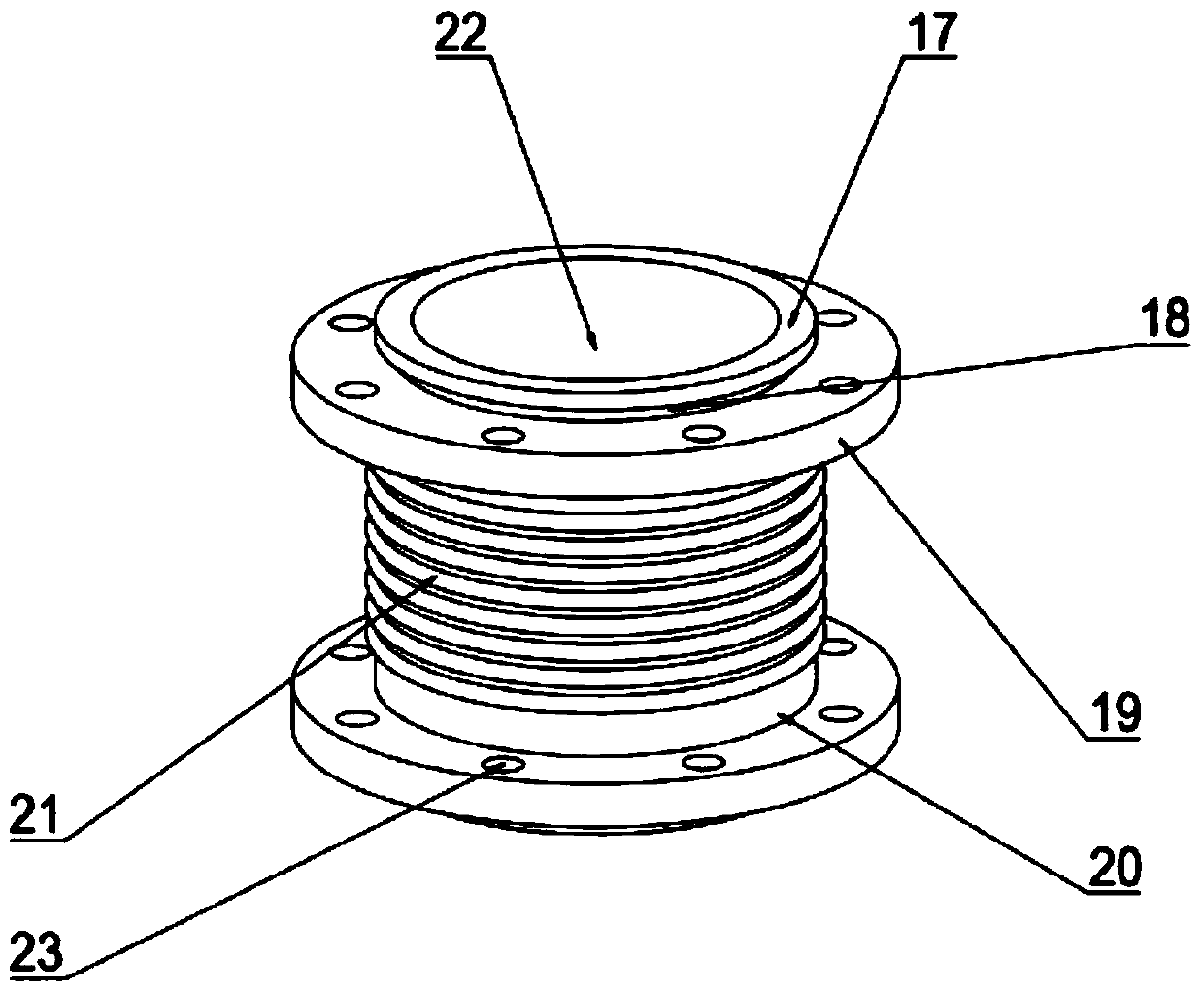

[0051]The capillary throttling structure system in the liquid helium temperature zone of the present invention consists of three parts. The first part is a semicircular cover plate, including a first semicircular cover plate 3, a second semicircular cover plate 4, a third semicircular cover plate 5 and a second semicircular cover plate. Four semi-circular cover plates 6; the second part is a retractable bellows 7; the third part is a capillary unit, including a first two-way joint 1, a second two-way joint 2 and a capillary 25.

[0052] The first semicircular cover plate 3, the second semicircular cover plate 4, the third semicircular cover plate 5 and the fourth semicircular cover plate of the first part of the liquid helium temperature zone capillary throttling structure system are consistent in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com