Reference block and flaw detection method for ultrasonic flaw detection of thick-wall high-pressure seamless steel pipe

A technology of seamless steel pipes and comparative test blocks, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and measuring devices, etc. The effect of saving working time, suitable weight and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments are not intended to limit the scope of the present invention.

[0033] The comparative test block of the present invention is used for ultrasonic flaw detection of thick-walled high-pressure seamless steel pipes, the material of which is carbon steel, the wall thickness is greater than or equal to 9 mm, and the maximum working pressure is 800 bar.

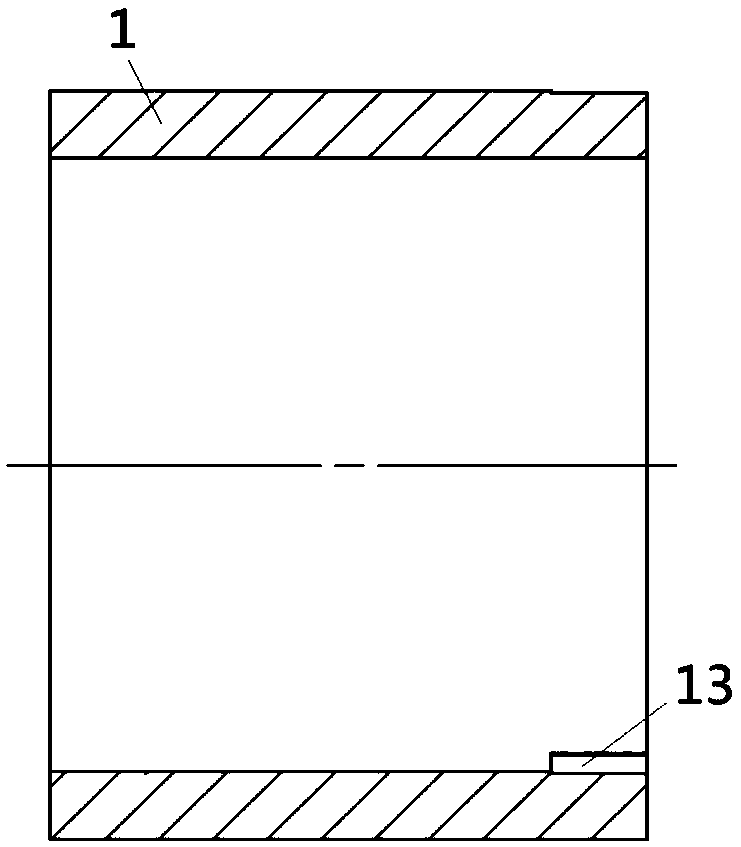

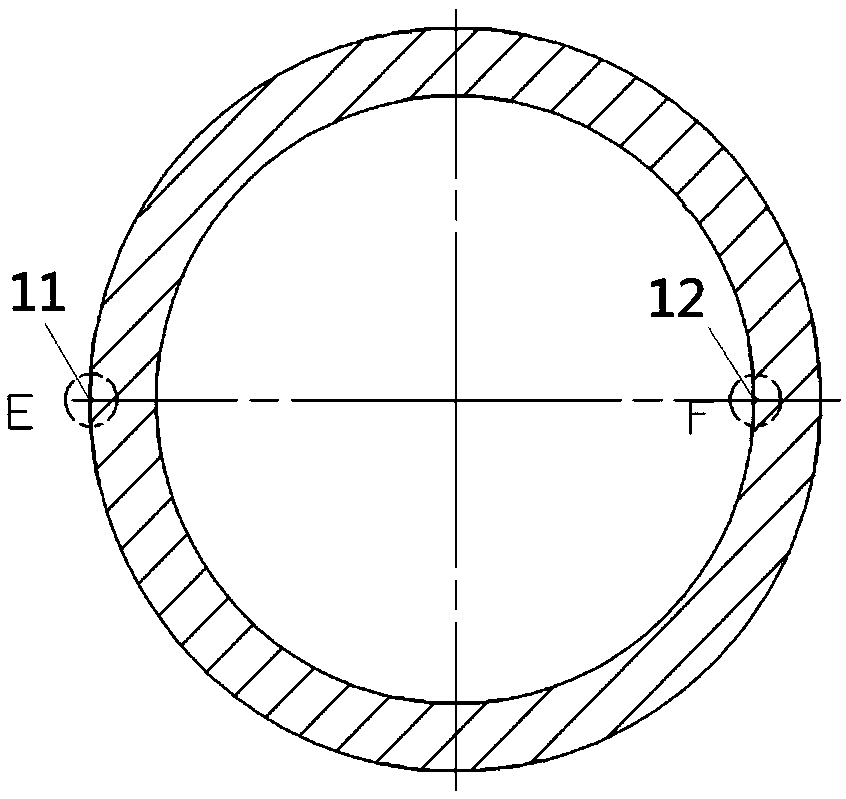

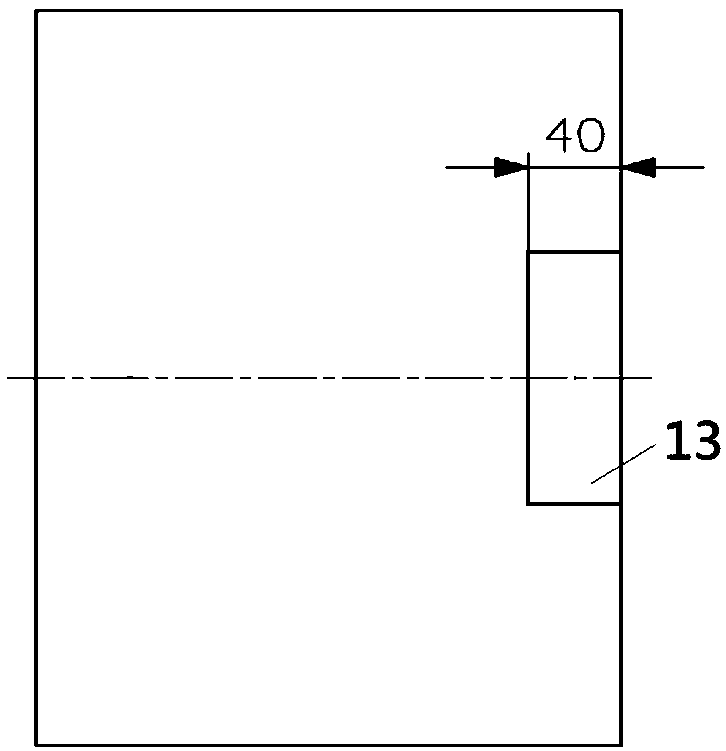

[0034] The comparison test block includes a test comparison test block 1 and an instrument calibration test block 2 .

[0035] Please refer to figure 1 , figure 2 and image 3 , the test comparison test block 1 is a pipe fitting structure, which is used as a comparison model in the process of ultrasonic flaw detection of the seamless steel pipe, please refer to figure 2 , the test comparison test block 1 includes an engraved groove 13 , a V-shaped groove 11 on the ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com