Computer-based steelmaking logistics simulation system

A simulation system, computer technology, applied in general control systems, control/regulation systems, comprehensive factory control, etc., can solve problems such as insufficient measurement information that can be directly used for high-temperature molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

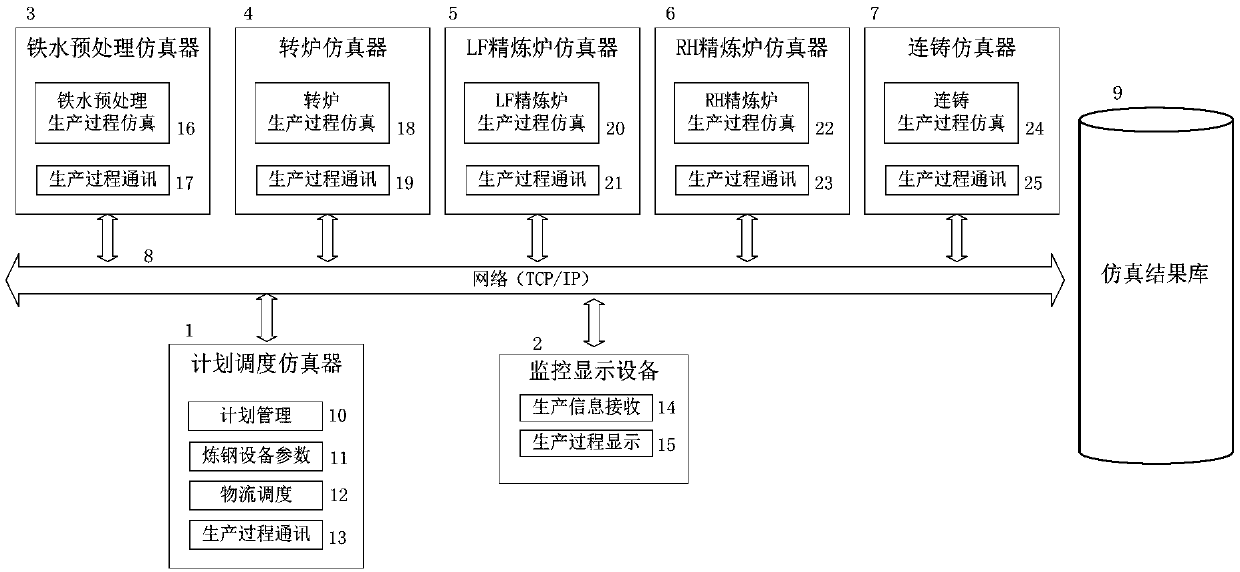

[0019] According to the present invention, a planning scheduling simulator 1, a monitoring display device 2, a molten iron pretreatment simulator 3, a converter simulator 4, an LF refining furnace simulator 5, a RH refining furnace simulator 6, and a continuous casting simulator are connected by an Ethernet local area network 8 7. The simulation result library 9 is formed. Among them, the planning scheduling simulator 1 builds a steelmaking production environment; the monitoring and display device 2 realizes the display of the simulation content; the simulation result library 9 realizes the storage of the simulation results; the molten iron pretreatment simulator 2 realizes the simulation of the molten iron pretreatment process; The converter simulator 4 realizes the simulation of the converter smelting production process; the LF refining furnace simulator 5 realizes the simulation of the ladle refining production process; the RH refining furnace simulator 6 realizes the simula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com