Image sensor and forming method thereof

A technology of image sensor and transmission gate, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve problems such as image lag, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the existing image sensor technology, in order to increase the full well capacity of the pixel unit, it is necessary to increase the PD area.

[0026] The inventors of the present invention have found through research that, in the prior art, it is difficult to increase the full well capacity of the pixel unit by directly increasing the depth or width of the PD region.

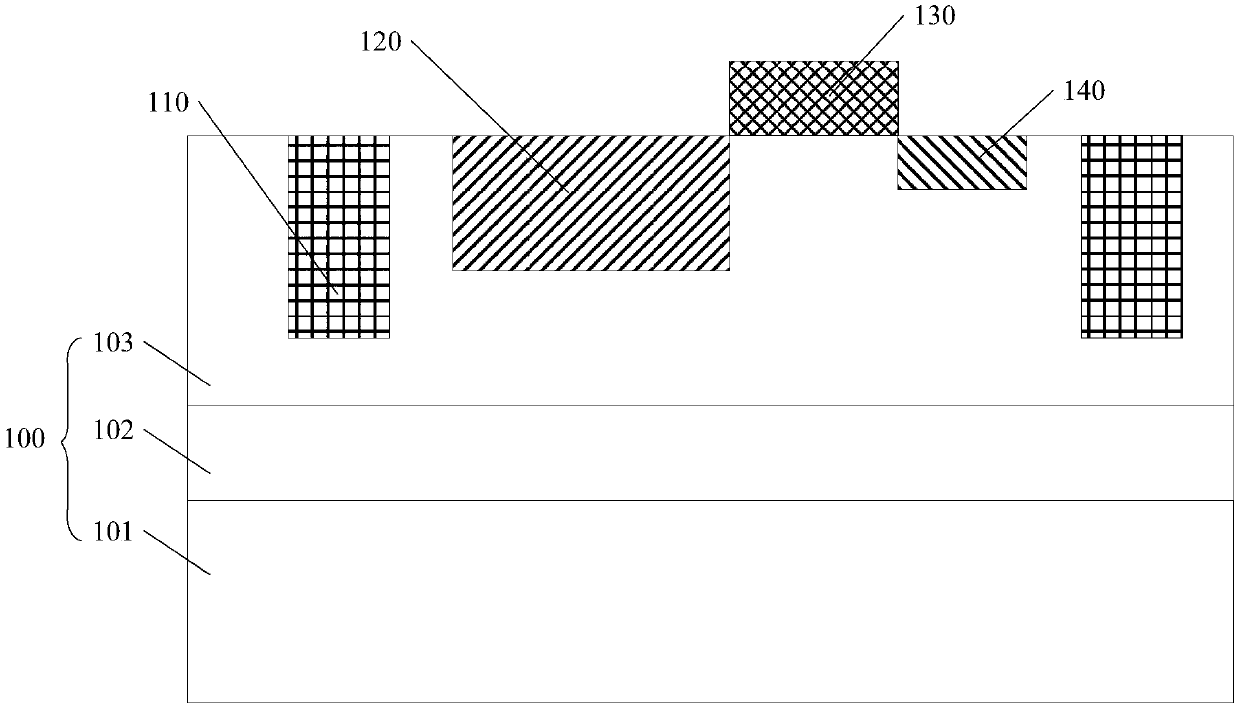

[0027] refer to figure 1 , figure 1 It is a schematic diagram of a device cross-sectional structure of an image sensor in the prior art.

[0028] The image sensor may include a semiconductor substrate 100 , and the semiconductor substrate 100 may include a stacked first silicon substrate layer 101 , a substrate oxide layer 102 and a second silicon substrate layer 103 .

[0029] The image sensor may further include a photodiode doped region 120 , a transfer gate 130 and a floating diffusion region 140 .

[0030] Wherein, the transfer gate can be located on the surface of the second silicon substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com