Lining for composite container pressure accumulator, composite container pressure accumulator, and manufacturing method of lining for composite container pressure accumulator

A composite container and pressure accumulator technology, applied to the outer wall of the container structure, manufacturing tools, pressure vessels, etc., can solve the problems of high cost of raw materials, thick storage container wall, increased container weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0144] Next, the present invention will be described more specifically based on examples. The following examples show preferred examples of the present invention, and the present invention is not limited by these examples.

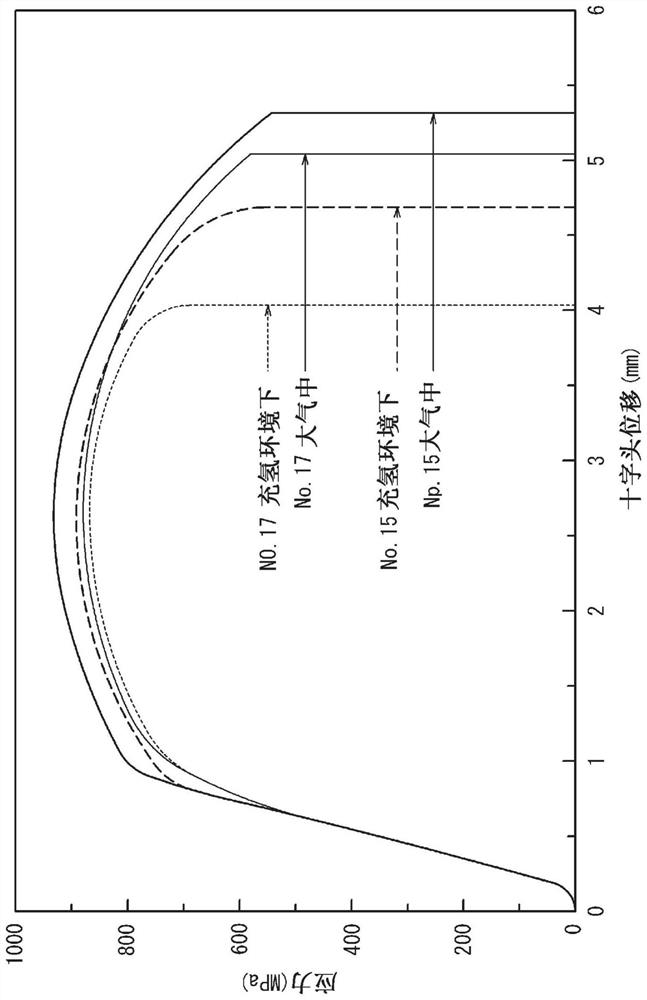

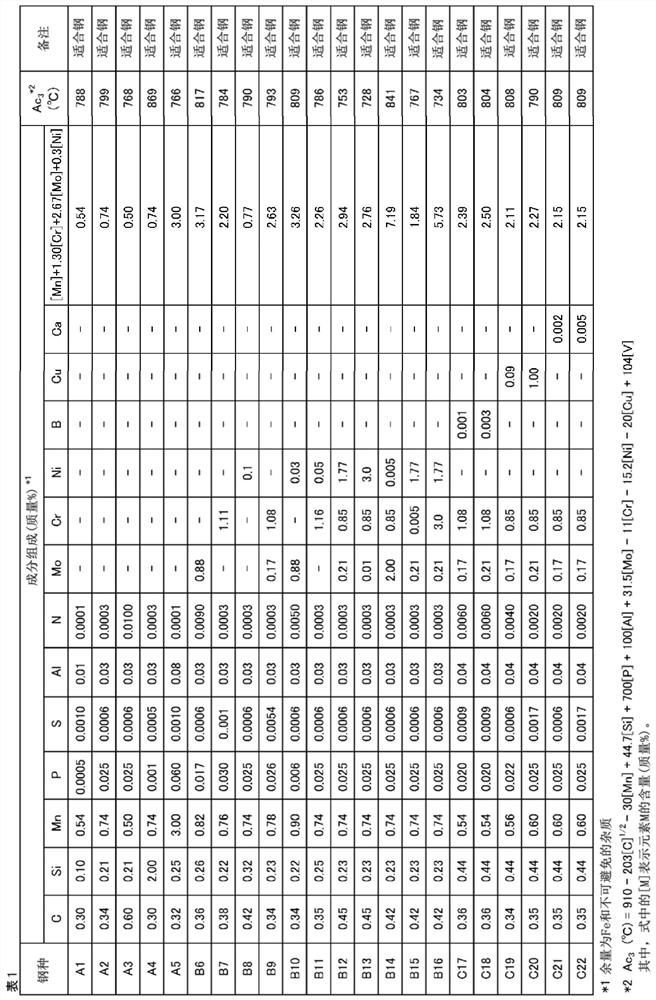

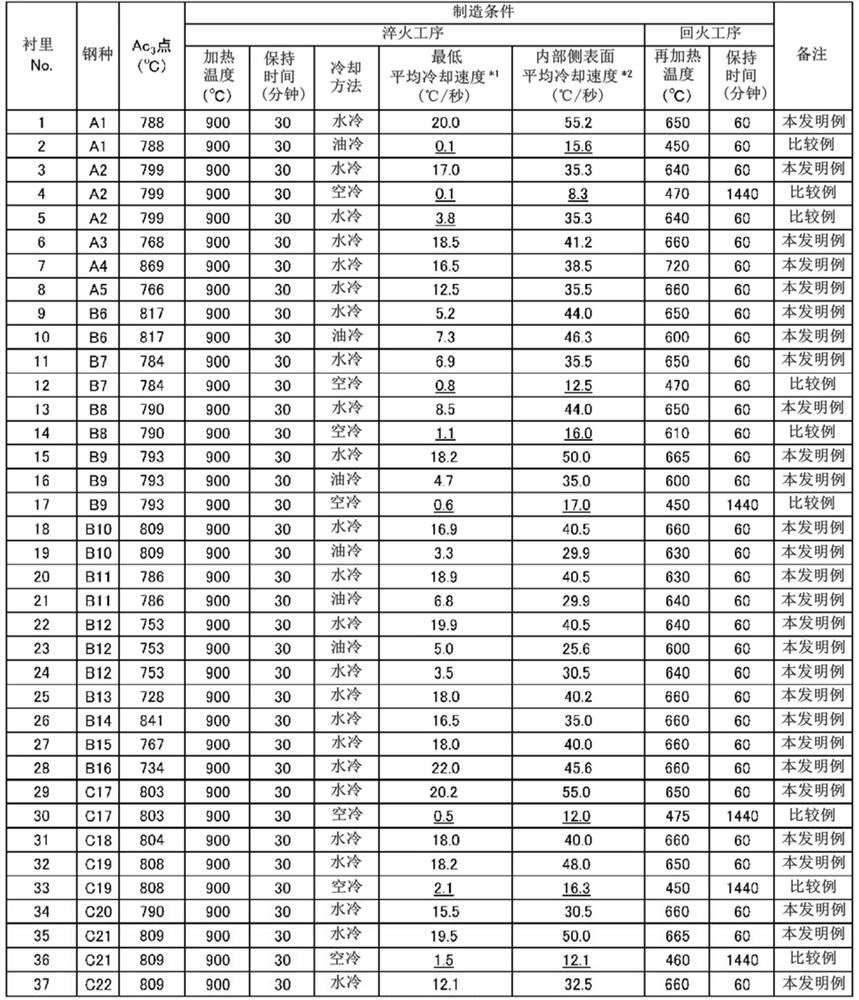

[0145] Liners for composite tank pressure accumulators made of steel materials with the composition shown in Table 1 were manufactured. The fabrication steps are described below. First, a billet having the composition shown in Table 1 was produced, and the billet was rolled and expanded with heat to obtain a seamless steel pipe. The production of the above-mentioned steel pipe is carried out under the conditions that pipe expansion is completed at 820° C. or higher. The obtained steel pipe was air-cooled, formed into a liner shape, and further quenched and tempered. Table 2 shows the quenching and tempering conditions. The minimum cooling rate in the quenching process shown in Table 2 was measured by installing a thermocouple on the inner side surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com