A method for simultaneously removing sulfur dioxide and nitrogen oxides from waste gas

A technology of sulfur dioxide and nitrogen oxides, which is applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of inability to improve synchronous removal efficiency and low removal rate of nitrogen oxides, and achieve improved waste gas removal effect and easy Operation and realization, the effect of good exhaust gas removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The exhaust gas in this embodiment comes from the simulated flue gas generated by the gas generating device. Before entering the synchronous desulfurization and denitrification packed tower, the simulated flue gas is first passed into the mixing device to mix the simulated flue gas with air.

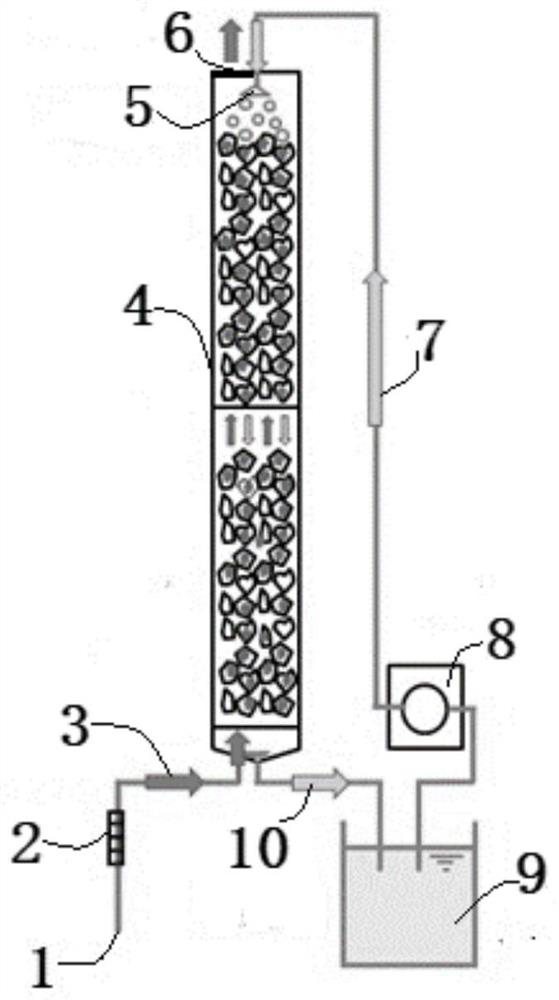

[0047] like figure 1 As shown, the air inlet 1, the gas flow meter 2, the air inlet pipeline 3, the packing container 4, the nutrient solution spraying device 5, and the exhaust port 6 of the biofilm packed tower for simultaneous removal of sulfur dioxide and nitrogen oxides in this embodiment , nutrient solution inflow pipeline 7, peristaltic pump 8, nutrient solution storage container 9 and nutrient solution outflow pipeline 10.

[0048] The air inlet 1 is used for waste gas to enter the packed tower, and the gas is passed through the air inlet 1, and enters the packing container 4 of the packed tower through the air inlet line 3, and the process is passed through the air inlet ...

Embodiment 2

[0057] This embodiment is basically the same as Embodiment 1, the difference is:

[0058] The concentration of sulfur dioxide at the air inlet 1 in this embodiment is 1500-1700mg / m 3 , the concentration of nitrogen oxides is 1200~1400mg / m 3 , The molar concentration ratio of sulfur dioxide and nitrogen oxides in the exhaust gas is 0.65:1.

[0059] The filler is ceramsite with a diameter of 200mm, and the desulfurization and denitrification treatment described in step 2) is carried out under an aerobic environment, and the aerobic environment is provided by air, and the oxygen concentration in the air is 20%. The flow is kept at 0.2m 3 / h, the gas residence time is 110 seconds, and the liquid-gas ratio is 40L / m 3 .

[0060]The operating temperature of the packed tower is 35°C.

[0061] After running for 2 cycles, detect the concentration of sulfur dioxide and nitrogen oxides in the exhaust gas at the outlet; after testing, the concentration of sulfur dioxide at the 6 outle...

Embodiment 3

[0063] This embodiment is basically the same as Embodiment 1, the difference is:

[0064] The concentration of sulfur dioxide at the air inlet 1 described in this embodiment is 2000-2200 mg / m 3 , the concentration of nitrogen oxides is 1150~1250mg / m 3 , The molar concentration ratio of sulfur dioxide and nitrogen oxides in the exhaust gas is 1.05:1.

[0065] The filler is a porous acid-resistant plastic material with a diameter of 100mm, and the desulfurization and denitrification treatment in the step 2) is carried out in an aerobic environment, the aerobic environment is provided by air, and the oxygen concentration in the air is 20 %, set the air flow to keep at 0.2m 3 / h, the gas residence time is 110 seconds, and the liquid-gas ratio is 40L / m 3 .

[0066] The operating temperature of the packed tower is 30°C.

[0067] After running for 2 cycles, detect the concentration of sulfur dioxide and nitrogen oxides in the exhaust gas at the outlet; after testing, the concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com