Rapid and batch forming apparatus of paper-based microfluidic chips

A technology of microfluidic chips and molding devices, which is applied in the direction of laboratory appliances, laboratory containers, chemical instruments and methods, etc., which can solve the problems of low accuracy, increased processing costs, and inability to guarantee the accuracy of sample flow channels, etc. problem, to achieve the effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

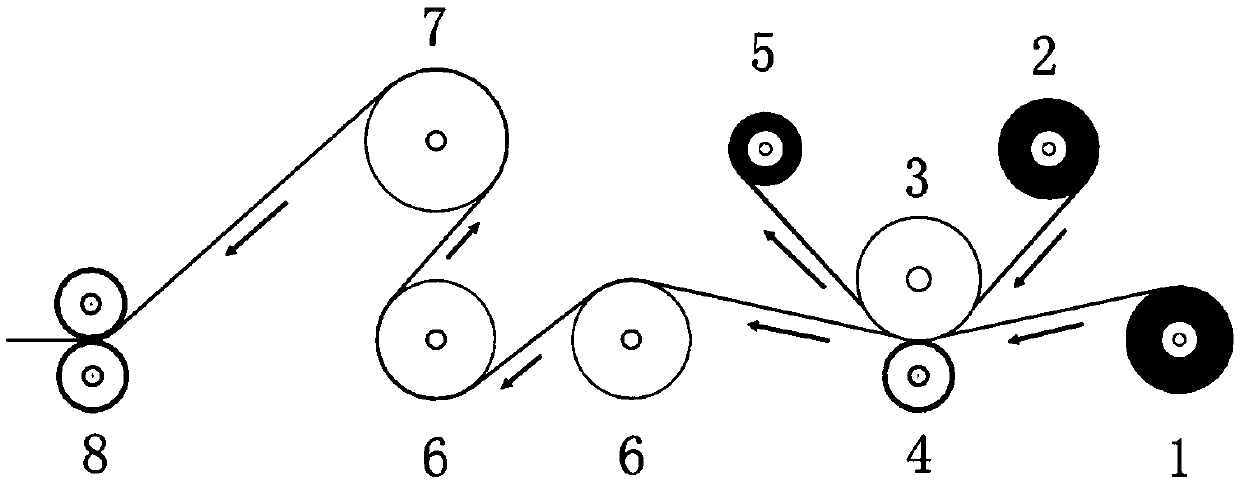

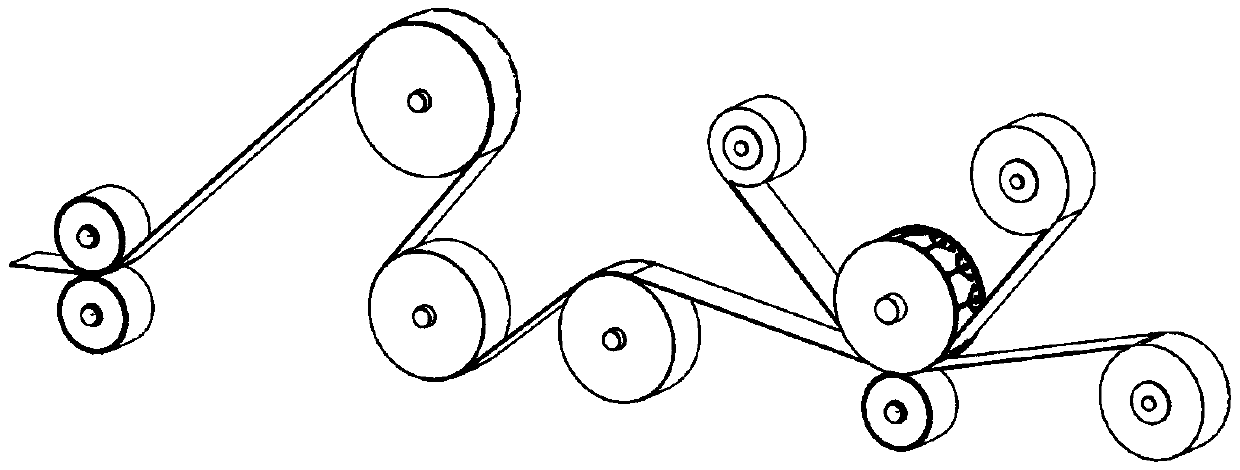

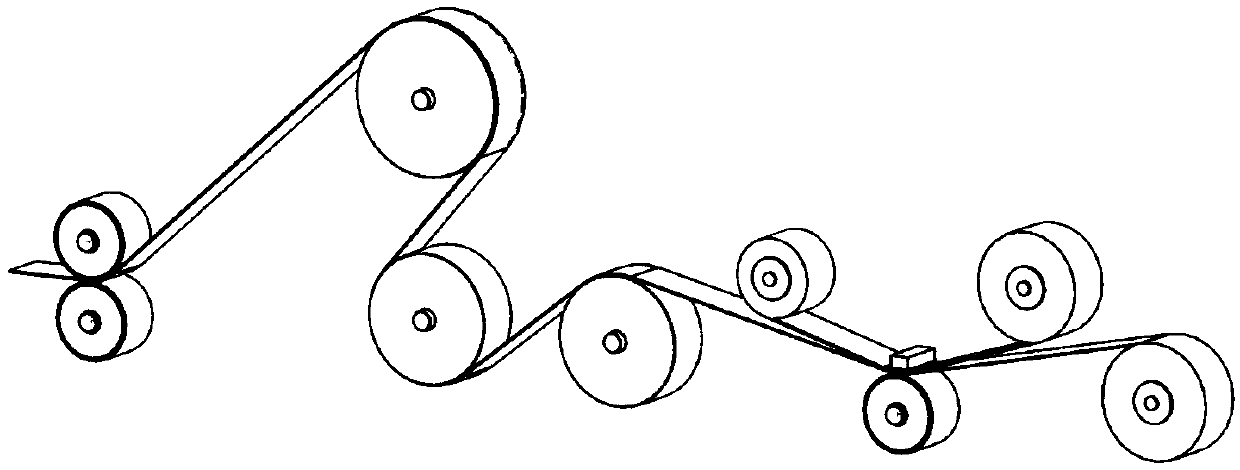

[0031] Firstly, place the 76.2mm wide hydrophilic paper roll and the wax-based carbon ribbon on the fixed shaft A (1) and fixed shaft B (2) respectively. Pass through the small gap between the hot pressing roller (3) and the traction roller (4), under the action of pressure and high temperature, the structure on the hot pressing roller is transferred from the wax-based carbon belt to the filter paper belt, and the waste wax-based carbon belt is sent to The fixed shaft C (5) is recycled, and the filter paper is further transported to the heating roller (6) for heating, and the wax on the filter paper penetrates into the gaps of the paper fibers after being heated and melted.

[0032] Then the paper tape passes through the cooling roller (7), and the cooled wax solidifies on the paper substrate to form a hydrophobic flow channel boundary, and the fluid moves in the hydrophilic paper fibers surrounded by the hydrophobic boundary through capillary action, realizing the microfluidic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com