Grinding device for silica gel production

A grinding device, silica gel technology, applied in grain processing, etc., can solve the problem of insufficient grinding of the grinding device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

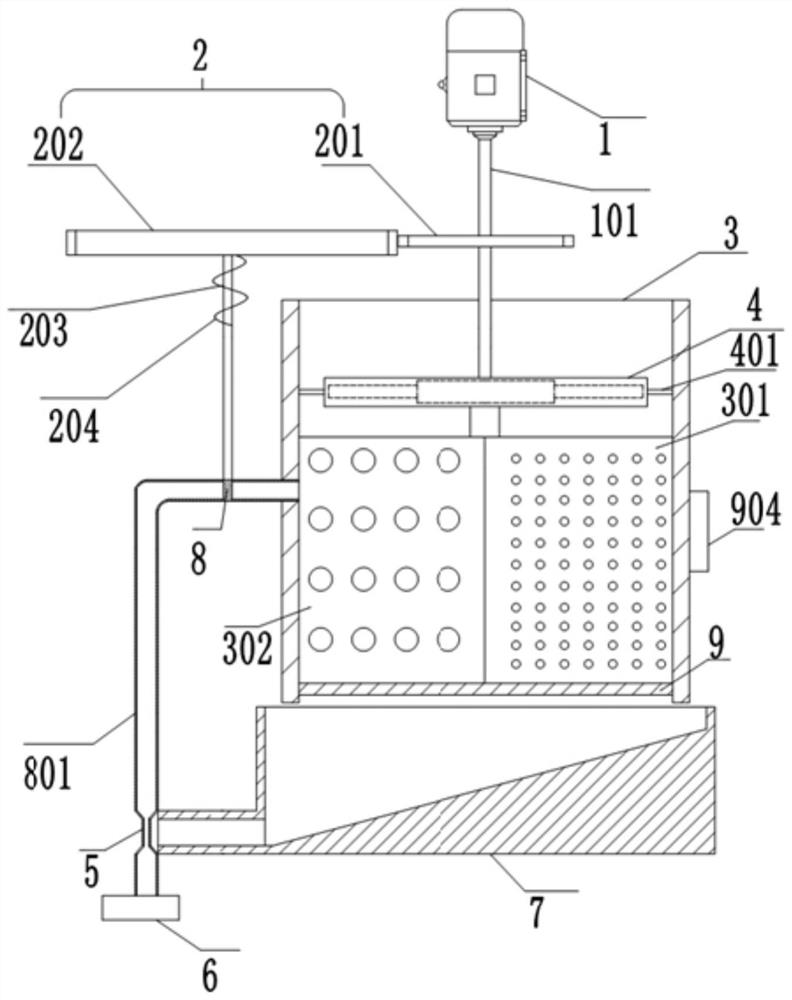

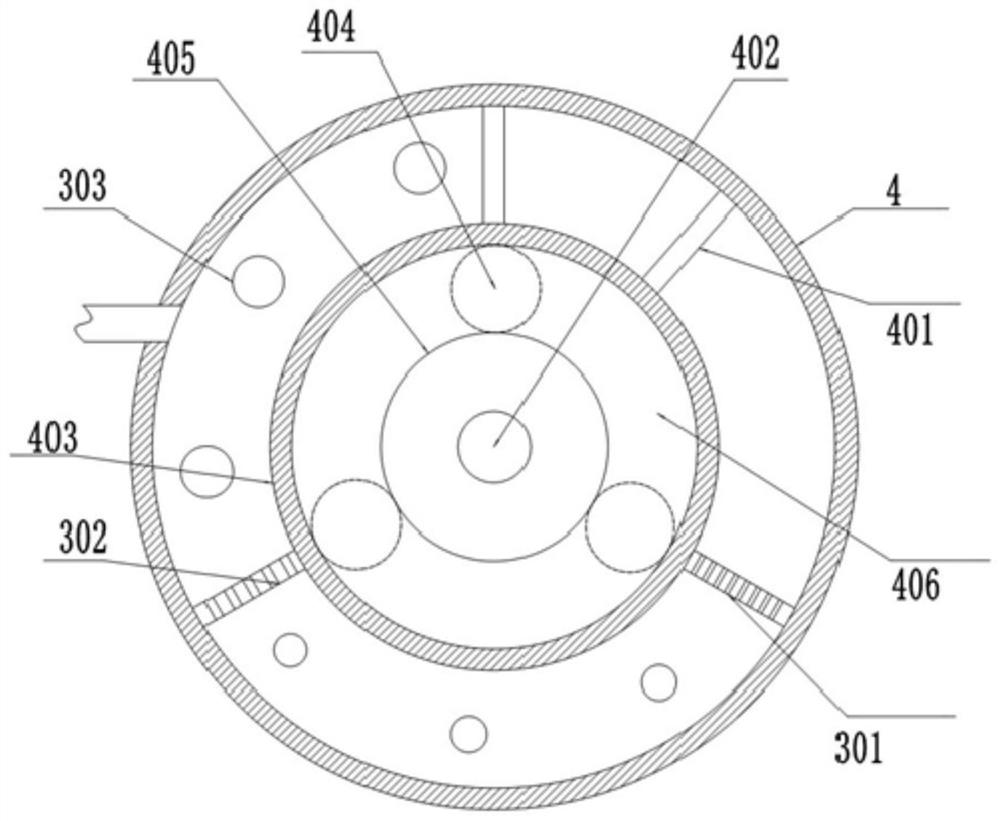

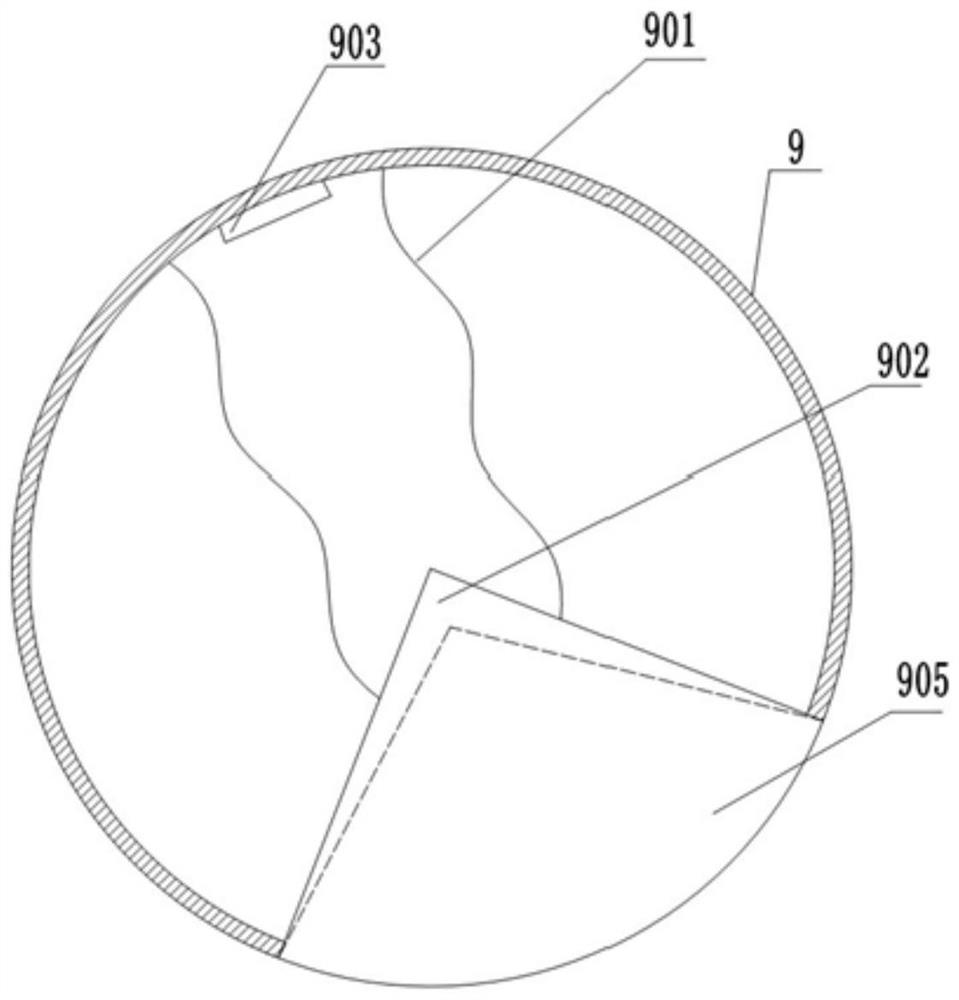

[0024] Grinding devices for silica gel production, such as figure 1 As shown, it includes a frame on which a motor 1 , an operating cylinder 3 and a collection chamber 7 are sequentially fixed from top to bottom. The two ends of the operating cylinder 3 are open. The operating cylinder 3 is provided with a planetary gear train 4 , a filtering and screening part and a partition 9 in sequence from top to bottom.

[0025] The left side of operating tube 3 is provided with material pipe 801 fixed on the frame and the blower 6 positioned at the lower side of material pipe 801, material pipe 801 includes a vertical section and a horizontal section positioned at the upper side of the vertical section, the horizontal section of the material pipe The section is provided with a pressure relief valve (not shown in the figure), and the vertical section of the feed pipe 801 is provided with a Venturi pipe 5, and a conduit is connected between the throat of the Venturi pipe and the collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com