A countersunk tool for indentable cnc machining

A cutting tool, indentation technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve problems such as inability to guarantee product quality, large fluctuations in depth dimensions, and inability to meet the requirements of CPK.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

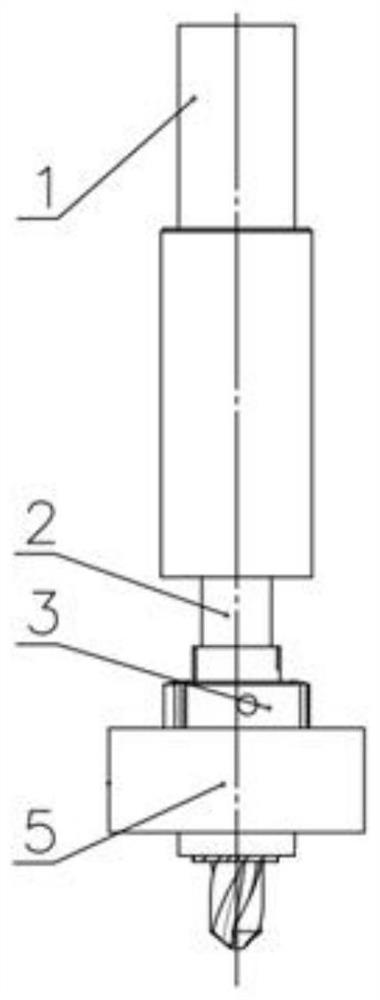

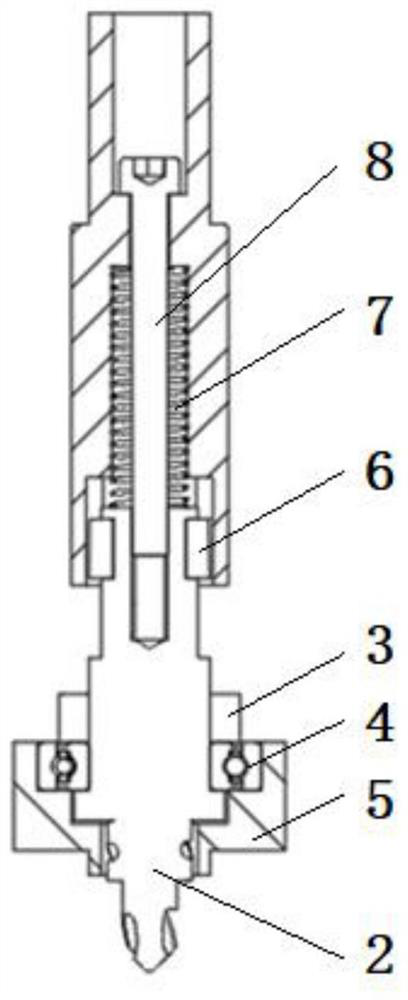

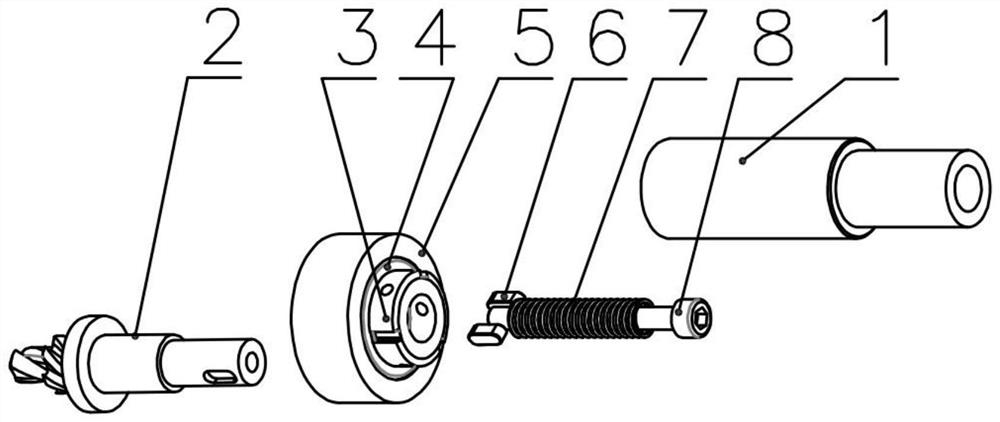

[0044] see figure 1 as well as image 3 , a retractable countersunk tool for CNC machining, including a tool holder 1 and a tool 2.

[0045] It also includes a retracting mechanism that can guide the tool 2 to retract axially toward the tool seat 1, and the tool seat 1 and the tool 2 are slidably connected through the retracting mechanism. The retracting mechanism includes a screw 8 and a spring 7, both of which are installed in the knife seat 1.

[0046] The knife seat 1 is provided with a channel that runs through up and down. From top to bottom, the channel is a head receiving groove for accommodating the head of the screw 8, a through hole for passing through the shank of the screw 8, and a hole for accommodating the spring 7. In the spring accommodation chamber, the inner diameter of the through hole is smaller than the inner diameters of the guide groove and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com