Carbomer derivative as well as preparation method and application thereof

A derivative, carbomer technology, applied in the field of carbomer derivatives and its preparation, can solve the problems of inability to make skin-piercing microneedles, carbomer does not have glucose responsiveness, and insufficient mechanical strength, etc. Achieve good glucose sensitivity, good glucose responsiveness, and good sugar responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

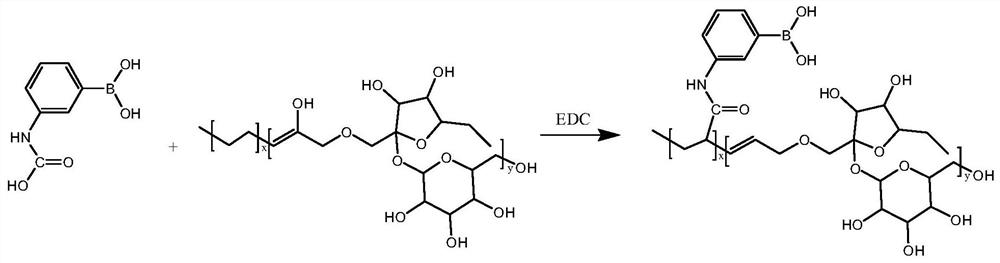

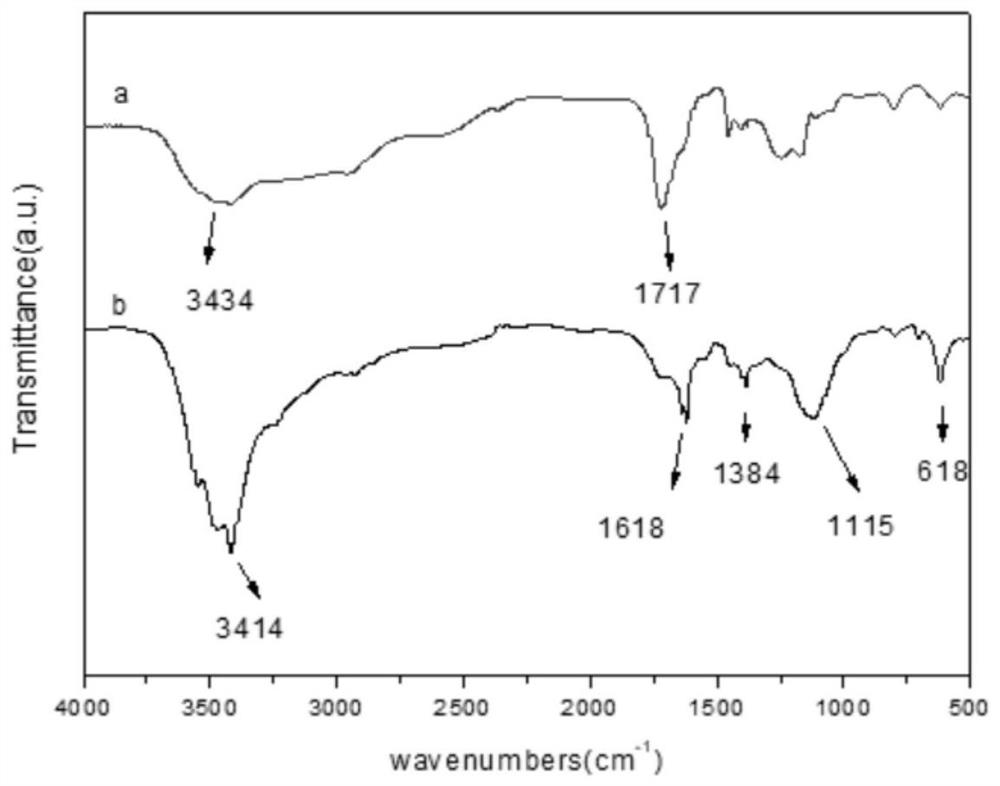

Method used

Image

Examples

Embodiment 1

[0046] 1. Weigh 0.20g carbomer, put it in a 50mL beaker, add 20mL deionized water, heat and stir at room temperature to dissolve (12h) to obtain 1% carbomer aqueous solution;

[0047] 2. Weigh 0.1g EDC into a 50mL flask, add 1% carbomer aqueous solution at 0°C, trigger for 1h, weigh 0.10g, 0.2g, 0.4g, 0.6g, 0.8g 3-aminophenylboronic acid respectively Add to the flask (corresponding ratio of carbomer to 3-aminophenylboronic acid, as shown in Table 1), incubate for 8h, and the reaction ends.

[0048] 3. Wash the product obtained in step 2 three times in water, ethanol and water respectively, weigh 0.5 g of the undried product after centrifugation, add 0.005 g of glycerin and 0.5 ml of deionized water and stir to form a homogeneous solution.

[0049] 4. Pour the solution into the polydimethylsiloxane microneedle mold, centrifuge at 3000 rpm, take out the microneedle mold and place it in a desiccator to dry.

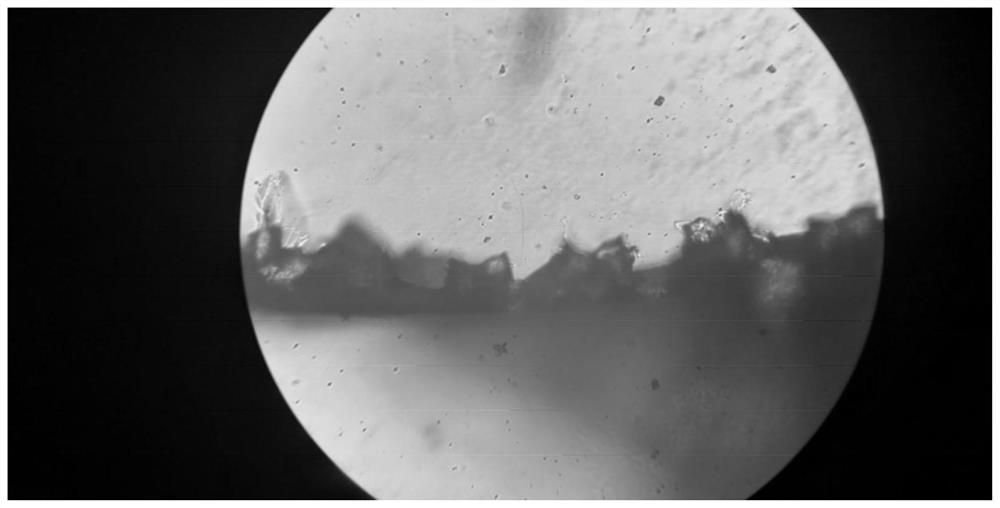

[0050] 5. Take out the dry microneedle mold, observe the shape of the ...

Embodiment 2

[0062] 1. Repeat step 1 of Example 1, weigh 0.05, 0.1, 0.2, 0.5, 1.0g of EDC in a 50mL flask, add 1% carbomer aqueous solution at 0°C, trigger for 1h, and weigh 0.4g of 3-amino Phenylboronic acid was added to the flask, incubated for 8h, and the reaction was completed.

[0063] 2. Wash the product prepared in step 2 three times in water, ethanol and water respectively, weigh 0.5 g of the undried product after centrifugation, add 0.005 g of glycerin and 0.5 mL of deionized water and stir to form a homogeneous solution.

[0064] 3. Pour the solution into the polydimethylsiloxane microneedle mold, centrifuge at 3000 rpm, take out the microneedle mold and place it in a desiccator to dry.

[0065] 4. Take out the dry microneedle mold, observe the shape of the microneedle with a microscope, and use the pressing method to test the mechanical strength of tinfoil simulated human skin, and apply a pressure of 10N. The material was soaked in 10 mM glucose, pH 7.4 PBS solution, and the s...

Embodiment 3

[0069] 1. Repeat step 1 of Example 1, weigh 0.1g of EDC into a 50mL flask, add 1% carbomer aqueous solution at 0°C, adjust the pH of the system to 3, 5, 7, 9, 11, and initiate for 1h. Weigh 0.4g of 3-aminophenylboronic acid into the flask, keep the temperature constant for 8h, and the reaction ends.

[0070] 2. Wash the product prepared in step 2 three times in water, ethanol and water respectively, weigh 0.5 g of the undried product after centrifugation, add 0.005 g of glycerin and 0.5 mL of deionized water and stir to form a homogeneous solution.

[0071] 3. Pour the solution into the polydimethylsiloxane microneedle mold, centrifuge at 3000 rpm, take out the microneedle mold and place it in a desiccator to dry.

[0072] 4. Take out the dry microneedle mold, observe the shape of the microneedle with a microscope, and use the pressing method to test the mechanical strength of tinfoil simulated human skin, and apply a pressure of 10N. The material was soaked in 10 mM glucose,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com