Lithium ionic secondary cell barrier, preparation and lithium ionic cell thereof

A secondary battery, lithium ion technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as short circuit at the edge of the positive current collector, achieve simple and easy operation in the production process, reduce safety accidents, and resist edge burrs Strong piercing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

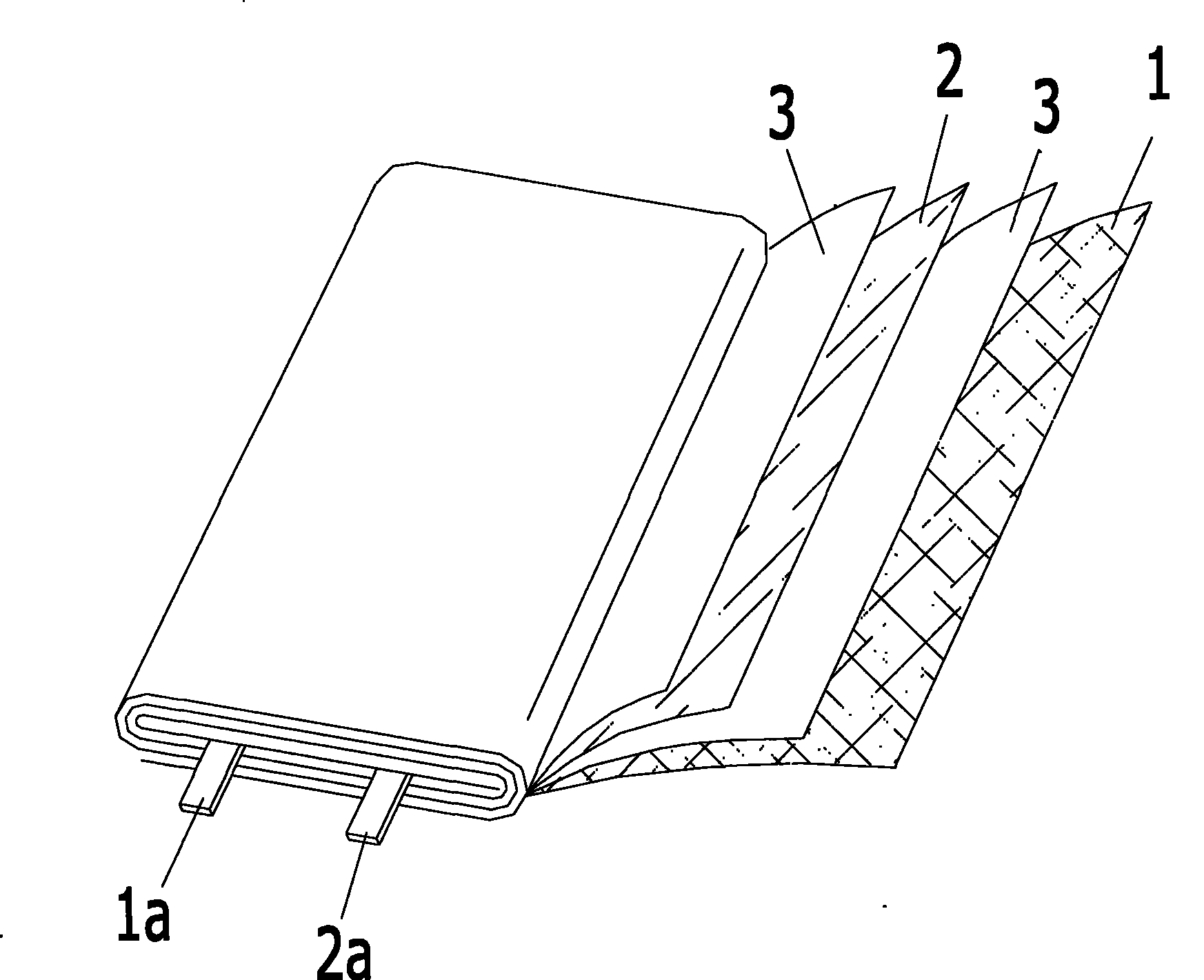

[0027] This example is used to illustrate the preparation method of the positive electrode of the battery provided by the present invention, the preparation of the diaphragm, and the lithium ion battery prepared by using the diaphragm.

[0028] (1) Preparation of positive electrode

[0029] Dissolve 30 grams of polyvinylidene fluoride (PVDF) in 450 grams of N-methylpyrrolidone (NMP) solvent to prepare a binder solution, and then mix 940 grams of LiCoO 2 Add 30 grams of acetylene black powder to the above solution, stir and mix evenly to obtain a positive electrode slurry; use a pulper to evenly coat the positive electrode slurry on both sides of an aluminum foil with a thickness of 18 microns to form a thickness of ? mm coating layer, and then put the pole piece in an oven and bake at 100° C. for 5 hours for sheeting treatment to obtain a positive pole piece with a thickness of 0.135 mm. Cut the sheet again to make a positive electrode of 550 mm (length) × 44 mm (width), each...

Embodiment 2

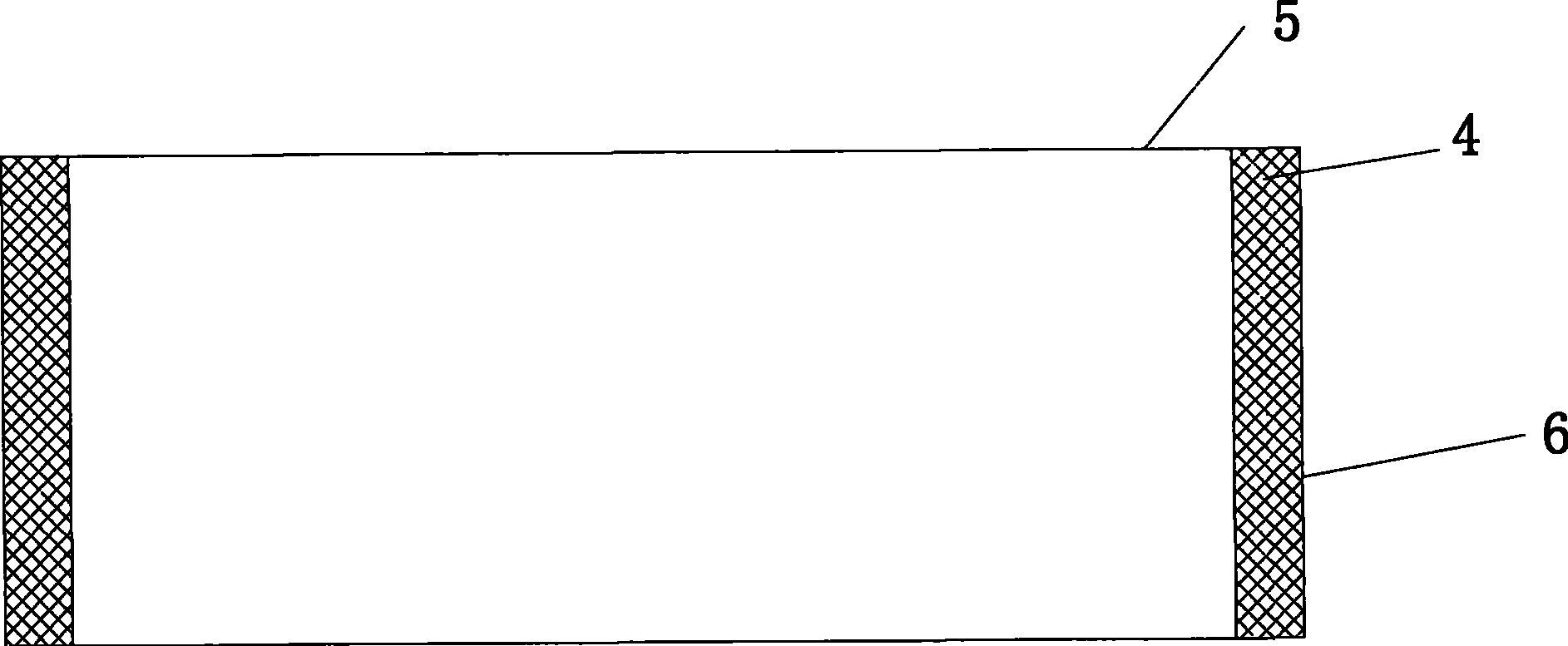

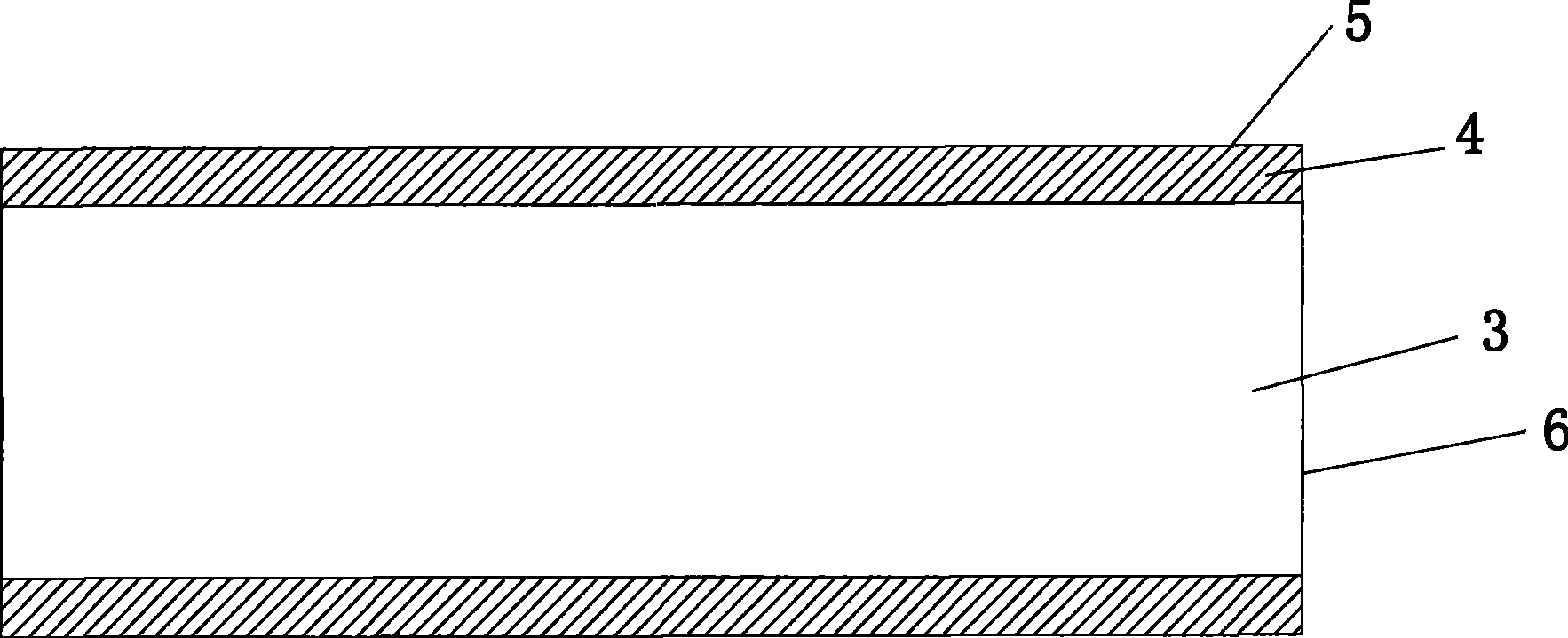

[0038] The heat-resistant resin is polyamide resin (PA6), 450 grams of N-methylpyrrolidone (NMP) solvent, and 85 grams of thermoplastic resin polymethyl methacrylate are stirred and dispersed evenly to obtain a liquid composition. This liquid composition is coated on (the model is celgard30008) polypropylene / polyethylene / polypropylene three-layer composite membrane such as image 3 On the edge of the long side shown, the width of the coating is 0.6 cm.

[0039] The rest of the steps were the same as in Example 1 to prepare lithium ion battery A2.

[0040] 100 identical batteries A2 were prepared by the method of Example 2.

Embodiment 3

[0042]The heat-resistant resin is polyphenylene sulfide resin (R-4), 450 grams of N-methylpyrrolidone (NMP) solvent, and 80 grams of thermoplastic resin polyethylene powder are stirred and dispersed evenly to obtain a liquid composition. This liquid composition is coated on (the model is celgard30008) polypropylene / polyethylene / polypropylene three-layer composite membrane such as image 3 On the edge of the long side shown, coat a width of 1.5 cm.

[0043] The rest of the steps were the same as in Example 1 to prepare lithium ion battery A3.

[0044] 100 identical batteries A3 were prepared by the method of Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com