A kind of ceramic slurry for lithium battery diaphragm and its preparation and application method

A technology of lithium battery diaphragm and ceramic slurry, which is applied in the field of electrochemistry to achieve the effects of strong piercing ability, good resistance to electrolyte corrosion, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

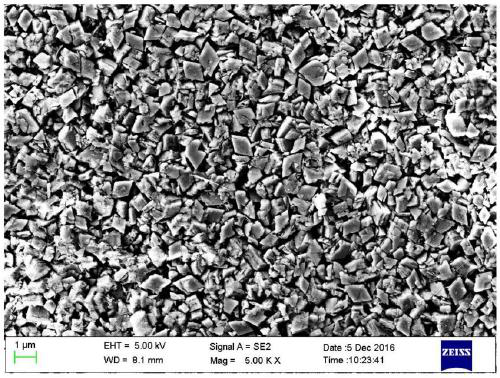

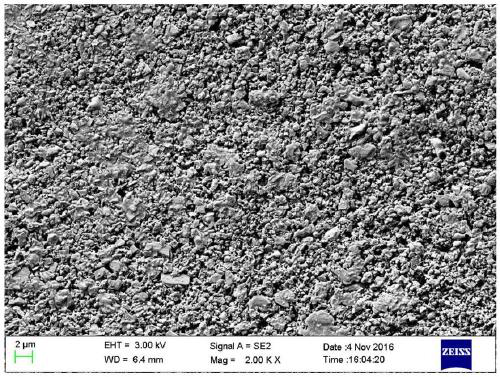

Image

Examples

Embodiment 1

[0023] First, disperse the dispersant into the solvent, then add the ceramic powder, and fully stir and mix in the double planetary mixer; at the same time, mix the binder and solvent in the double planetary mixer; after the two slurries are mixed evenly, The mixed slurry of the ceramic powder is added to the mixed slurry of the binder. Then turn on the double planetary mixer, firstly stir at a low speed, shear at a low speed, and scrape the wall at intervals for 2-6 hours. After all the large particles in the slurry are dispersed, start rapid stirring and high-speed shearing for 1-4 hours until the slurry is evenly mixed. Finally, take a little slurry and test the viscosity, solid content and settlement.

[0024] The preparation method is: firstly weigh 1wt% PEG (polyethylene glycol) and dissolve it in the aqueous solution, stir and dissolve it fully, then add 90wt% boehmite powder, the particle size is D50=0.5μm, double planetary stirring The speed is 5rpm, the dispersion ...

Embodiment 2

[0029] First weigh 5wt% PVP and dissolve it in NMP, stir and dissolve it fully, then add 80wt% alumina powder, the particle size is D50=0.2μm, the double planetary stirring speed is 3rpm, the dispersion speed is 600rpm, after 8min Scrape the wall; then adjust the stirring rate to 12rpm, the dispersion rate to 1000rpm, scrape the wall after 15min, then adjust the stirring rate to 30rpm, the dispersion rate to 1600rpm, and continue stirring for 1.5h. At the same time, 15wt% of PVDF was dispersed into NMP at a stirring rate of 15rpm and a dispersion rate of 900rpm. After 10min, the wall was scraped, then vacuum stirred at a stirring rate of 40rpm and a dispersion rate of 1400rpm, and stirred for 2h. Finally, add the dispersed ceramic slurry to the glue, turn on the agitator, the stirring rate is 10rpm, the dispersion rate is 500rpm, scrape the wall after 20min, turn on the vacuum, adjust the stirring rate to 30rpm, and the dispersion rate is 1300rpm. The viscosity of the material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com