Battery tab laser cutting device

A battery tab and laser cutting technology, which is applied to laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low cutting accuracy, floating and bulging, and wrinkles, so as to achieve stable cutting process and eliminate Potential safety hazard, wrinkle prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

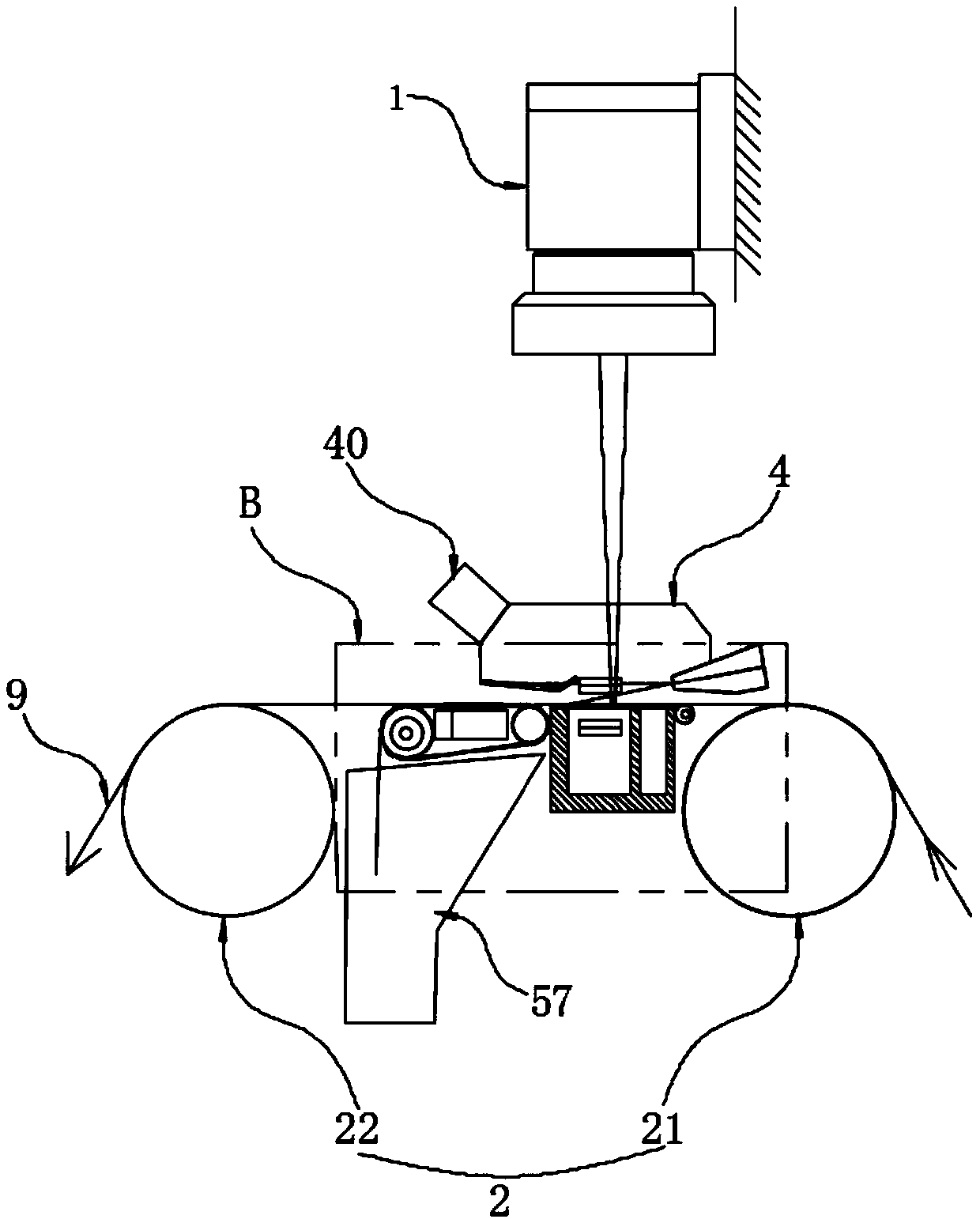

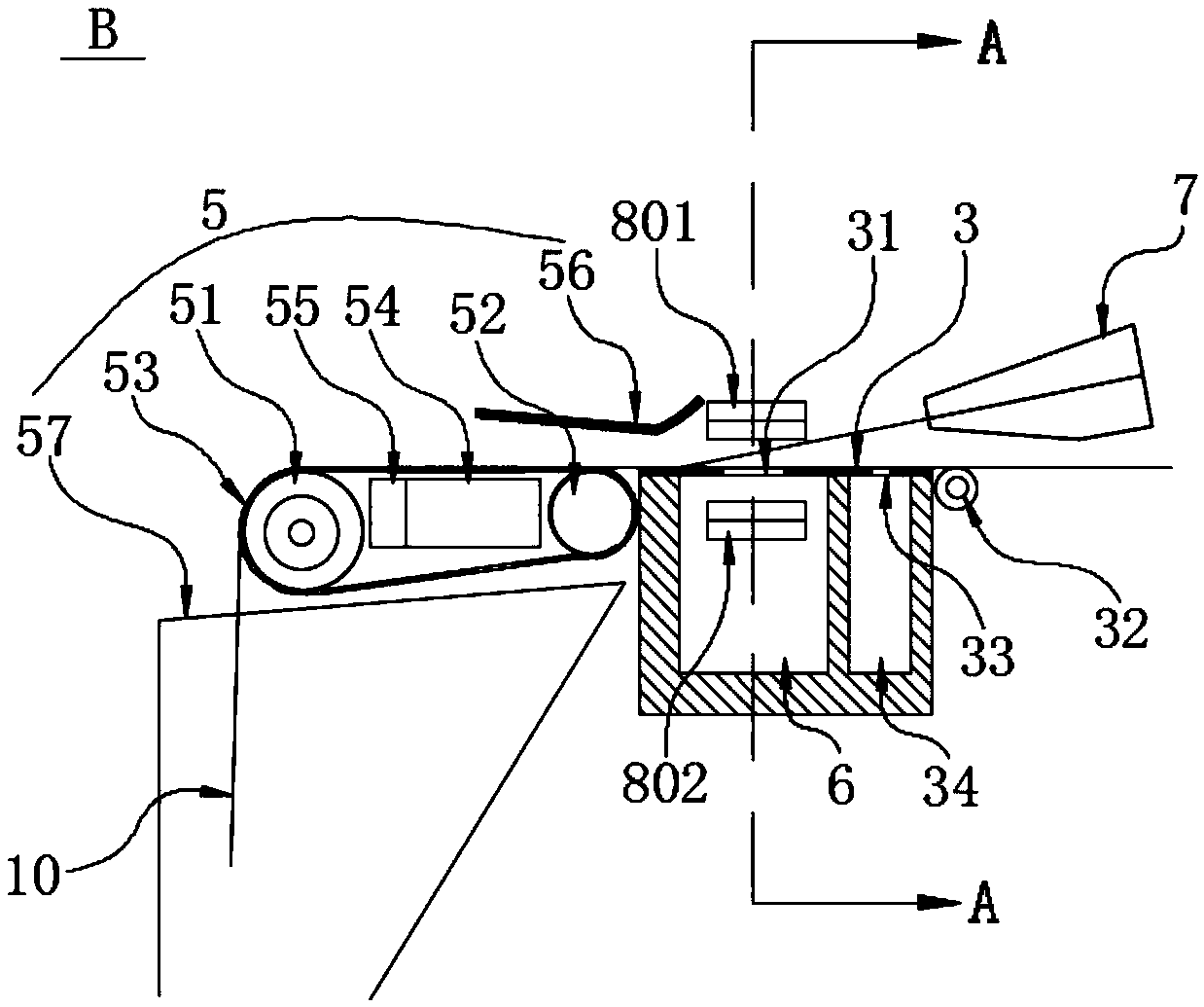

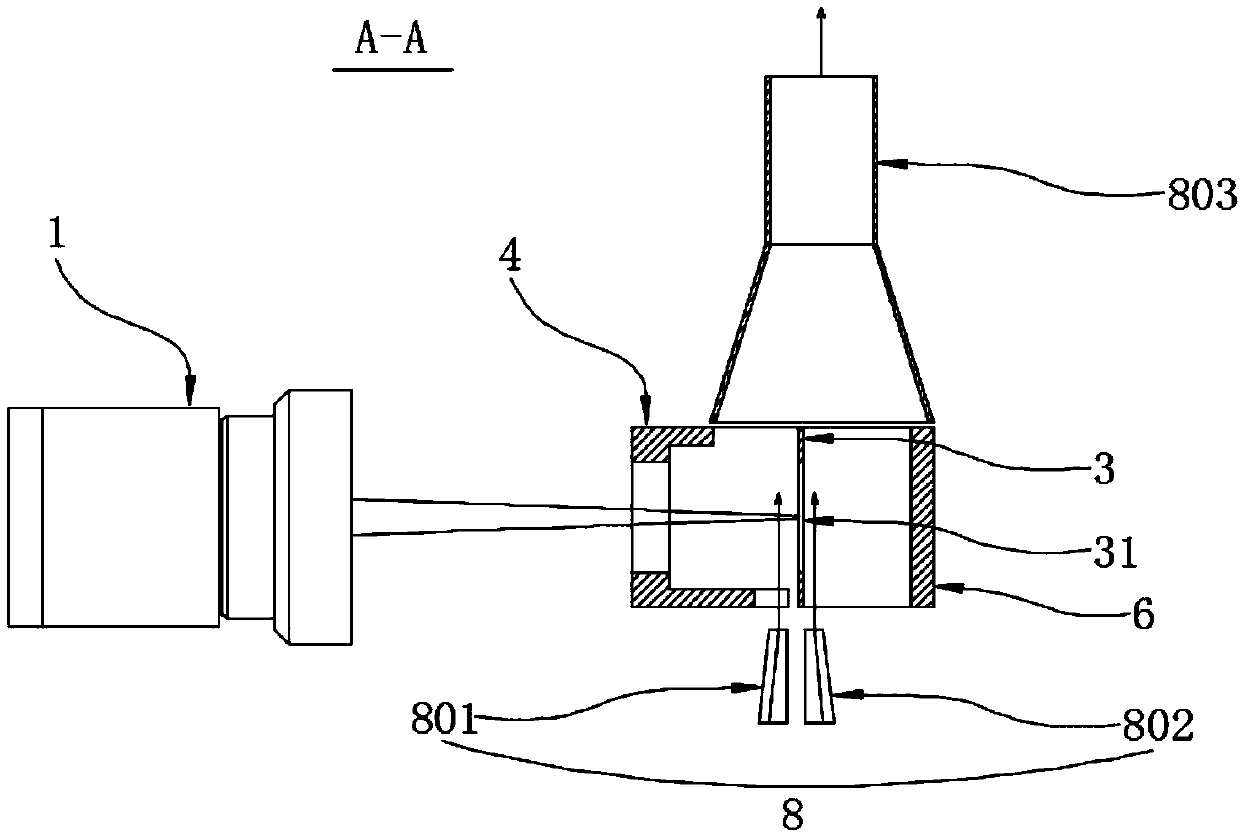

[0037] The battery tab laser cutting device of this embodiment is used for laser cutting the tab. see figure 1 As shown, the cutting device includes a laser head 1, a roller assembly 2, a cutting pallet 3, a dust cover 4 and a waste material unloading mechanism 5; the roller assembly includes a feed roller 21 and a discharge roller 22; the cutting Supporting plate 3 is arranged between described feeding roller 21 and described discharge roller 22; Said cutting supporting plate 3 has cutting opening 31; Said cutting opening 31 is positioned at the optical path of light output of said laser head 1; So The inlet end of the dust removal cover 4 is set at the cutting opening 31 ; the waste material unloading mechanism 5 is set at the discharge end of the cutting pallet 3 .

[0038] During laser cutting of battery tabs, the battery tabs unwind and pass through the feed roller 21 of the roller assembly 2 and enter the cutting pallet 3, and when the battery tabs pass through the cutt...

Embodiment 2

[0053] The battery lug laser cutting device of this embodiment is the same as that of Embodiment 1, the difference is that, see Figure 4 with Figure 5 Shown, the waste material unloading mechanism 5 of this device is suction waste material wheel 50. The waste suction wheel 50 is located at the discharge end of the cutting pallet 3 , and is located on the other side opposite to the inlet of the dust removal cover 4 along the running track of the cut battery tab. Wherein, the suction waste chamber 57 is located between the discharge end of the cutting pallet 3 and the feed end of the discharge roller 22, and is used to discharge the discharge end of the waste suction wheel 50 after cutting the battery. The waste side of the ear is collected by adsorption.

[0054] Among them, see Figure 6a with Figure 6b As shown, the waste suction wheel 50 is divided into a vacuum absorption area 501 , a vacuum breaking area 503 and a free area 502 along the radial section of the wheel;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com