Optical fiber plastic coating anti-jitter fiber pay-off device and system

An anti-shake, optical fiber technology, which is applied in the field of optical fiber sleeve plastic production, can solve the problems of increasing the optical fiber jitter amplitude, lengthening the route, and increasing the number of pay-off racks, etc., to improve the anti-shake effect, solve the jitter problem, and realize the optical fiber stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

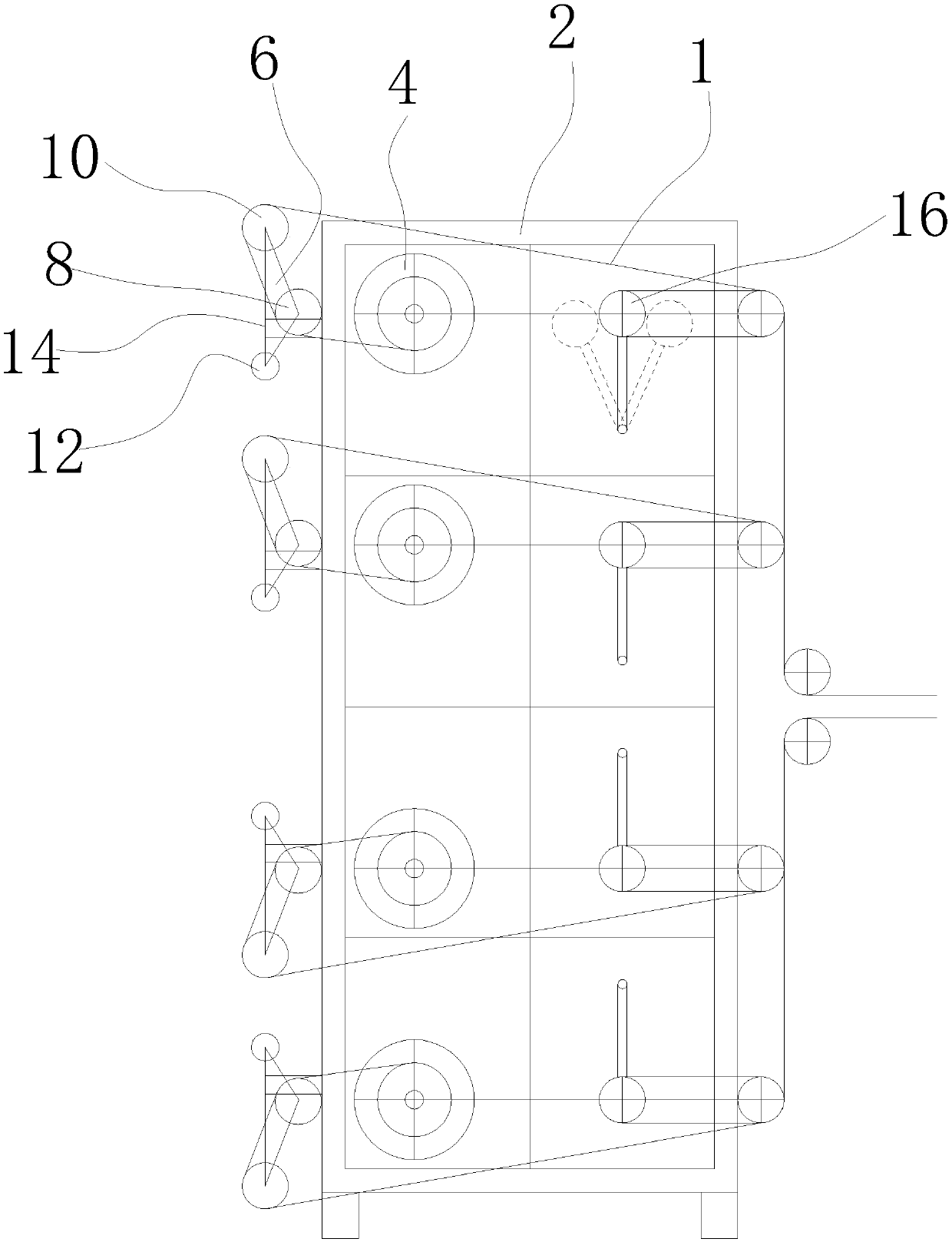

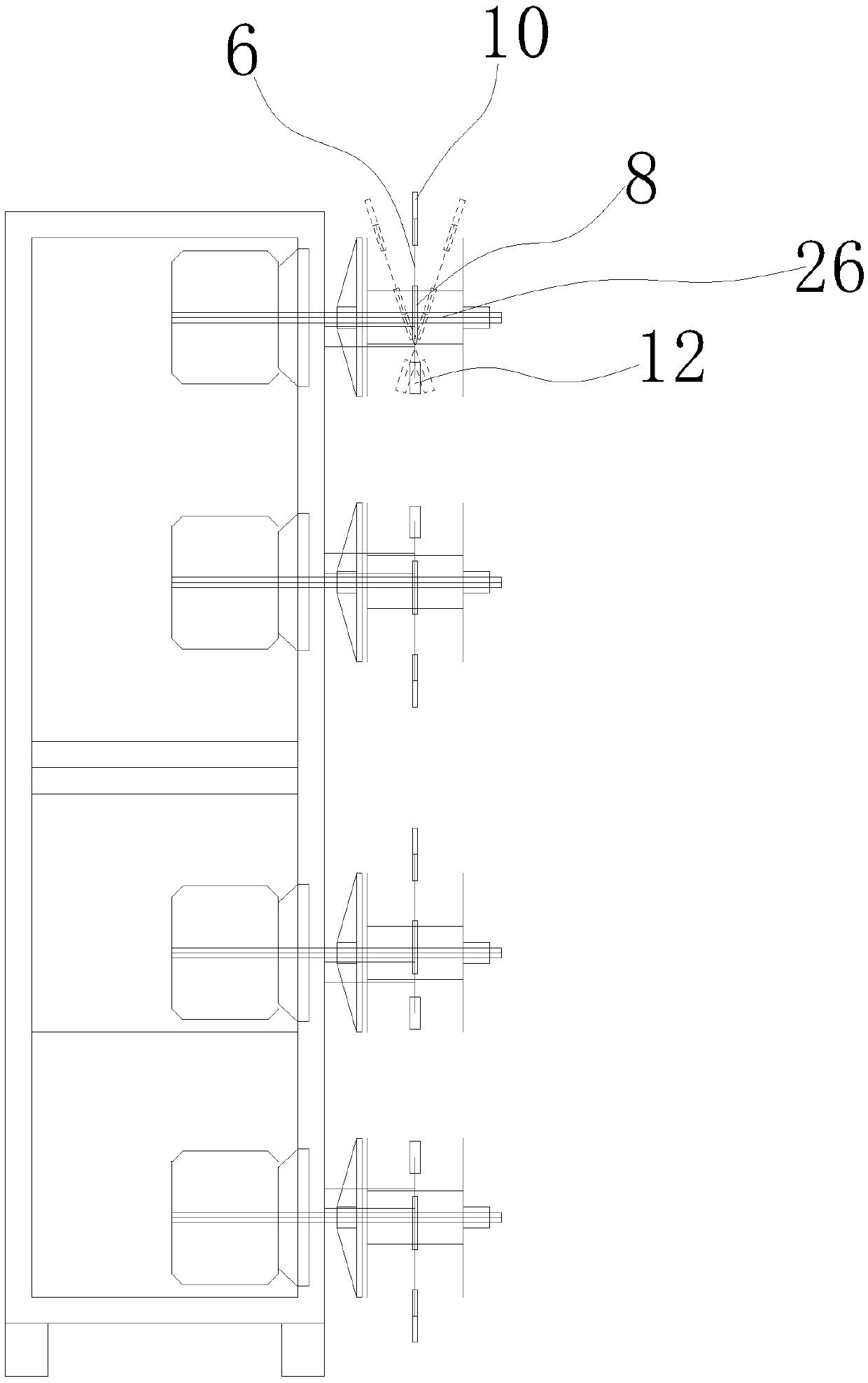

[0023] Such as figure 1 , as shown in 2, this embodiment discloses an anti-vibration fiber pay-off device for optical fiber sheathing, including a pay-off frame 2, an optical fiber reel 4 and a dancing tension guide wheel 16, and the above-mentioned optical fiber reel 4 passes through the pay-off shaft Installed on the pay-off frame 2, and rotate the fiber with the above-mentioned pay-off shaft, the swing guide wheel assembly is also installed on the above-mentioned pay-off frame 2, the above-mentioned swing guide wheel assembly includes a balance wheel bracket 6, and is installed on the above-mentioned balance wheel The first fiber guide wheel 8, the second fiber guide wheel 10 and the counterweight 12 on the support 6; the wheel axles of the first fiber guide wheel 8 and the second fiber guide wheel 10 are all arranged parallel to the disk axis of the fiber optic disk tool 4; The balance wheel bracket 6 is rotatably connected to the pay-off frame 2 through a swing shaft 26 ,...

Embodiment 2

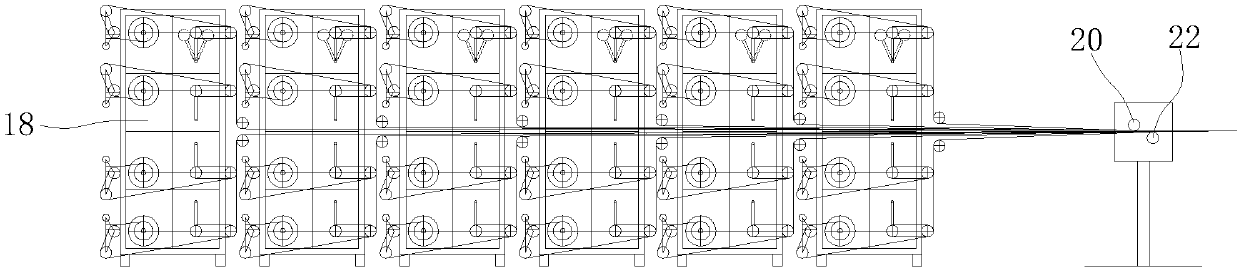

[0029] Such as image 3 , as shown in 4, this embodiment discloses an anti-shake fiber payout system for optical fiber sheathing, which cooperates with the production of multi-core optical fiber sheathing, including a mounting frame 18, an anti-shake fiber payout device with the above structure and a For the fiber collection guide wheel, several of the above-mentioned anti-shake fiber-spraying devices are sequentially installed on the above-mentioned installation frame 18 from top to bottom, or / and several of the above-mentioned anti-shake fiber-spraying devices are arranged sequentially along the optical fiber moving direction and installed on the above-mentioned on the mounting frame 18.

[0030] Specifically, in order to cooperate with the plastic production of multi-core optical fibers, the number of fiber releasing devices configured in the fiber releasing system is directly related to the number of optical fiber cores in the optical cable. A fiber pay-off device with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com