Cement slurry thickener and preparation method and application thereof

A technology of cement slurry and thickener, applied in the field of building materials, can solve problems such as poor application effect of nanomaterials, and achieve the effects of improving thickening effect, changing rheology, and improving consistency and viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The cement slurry thickener of this embodiment includes components by mass fraction: 4% graphene oxide, 3% polypropylene, 2% methylpyrrolidone, and the balance is water.

[0022] The above-mentioned cement slurry thickener is specifically prepared through the following steps:

[0023] 1) 4% graphene oxide is added to water, stirred for 30min to obtain a graphene oxide solution;

[0024] 2) The graphene oxide solution is carried out ultrasonic dispersion for the first time, then, add 3% polypropylene and 2% methylpyrrolidone, stir evenly, and carry out ultrasonic dispersion for the second time, wherein, the dispersion time of ultrasonic dispersion for the first time is 3h, the dispersion time of the second ultrasonic dispersion is 1h, and the cement slurry thickener of this embodiment is obtained.

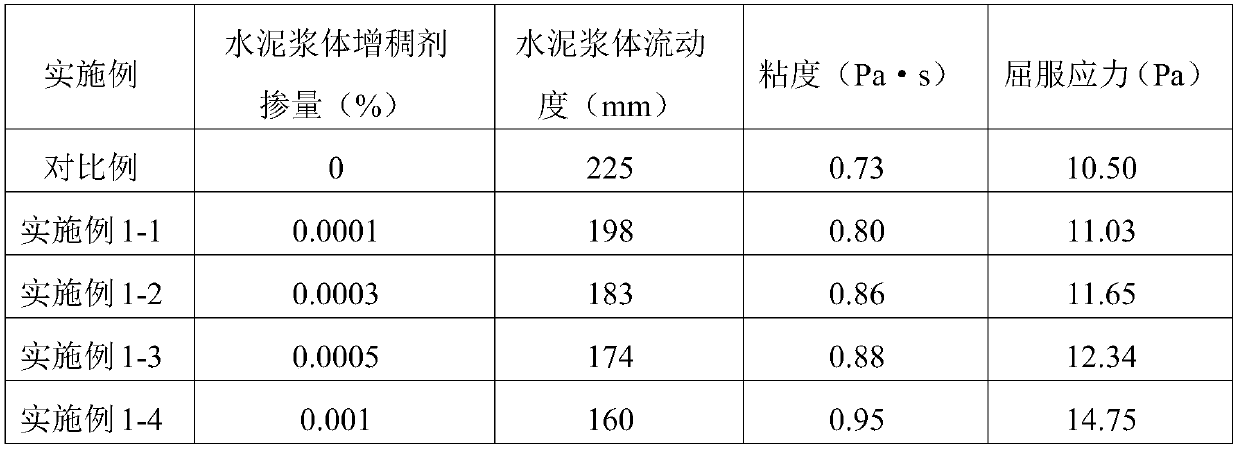

[0025] The above-mentioned cement slurry thickener is used in cement concrete, wherein, the dosage of cement slurry thickener is 0.0001%~0.001% of the amount of cementitious...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com