A special admixture for assembled mortar products

A prefabricated and admixture technology, applied in the field of mortar products, can solve the problems of unstable strength, high cost and general effect, and achieve the effects of accelerating the early hydration rate, solving the poor fluidity and improving the early strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

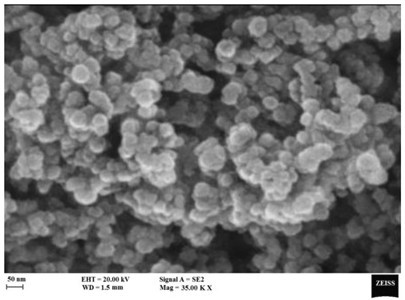

Image

Examples

Embodiment 1

[0093] The prefabricated mortar product special admixture of the present embodiment includes the following formulation components in parts by weight,

[0094] 5 parts of superplasticizer powder,

[0095] 35 parts of rubber powder,

[0096] 3 parts retarder,

[0097] 5 parts of defoamer,

[0098] 50 parts of stimulating agent.

[0099] Among the above-mentioned special admixtures for assembled mortar products,

[0100] The preparation method of described water reducing agent powder is as follows,

[0101] Prepare HPEG monomer, ammonium persulfate, bottom water, material A and material B, wherein the mass ratio between HPEG monomer, ammonium persulfate and water is 400:3:240, and material A includes acrylic acid, acrylamide, methyl The mass ratio between sodium propylene sulfonate and water, acrylic acid, acrylamide, sodium methacrylene sulfonate and water is 36:10:5:70, wherein material B includes thioglycollate, thioglycolic acid and water. , The mass ratio between thiog...

Embodiment 2

[0124] The prefabricated mortar product special admixture of the present embodiment includes the following formulation components in parts by weight,

[0125] 10 parts of superplasticizer powder,

[0126] 30 parts of rubber powder,

[0127] 5 parts of retarder,

[0128] Defoamer 2 parts,

[0129] 60 parts of stimulating agent.

[0130] Among the above-mentioned special admixtures for assembled mortar products,

[0131] The preparation method of described water reducing agent powder is as follows,

[0132] Prepare HPEG monomer, ammonium persulfate, bottom water, material A and material B, wherein the mass ratio between HPEG monomer, ammonium persulfate and water is 400:3:240, and material A includes acrylic acid, acrylamide, methyl The mass ratio between sodium propylene sulfonate and water, acrylic acid, acrylamide, sodium methacrylene sulfonate and water is 36:10:5:70, wherein material B includes thioglycollate, thioglycolic acid and water. , The mass ratio between thio...

Embodiment 3

[0155] The prefabricated mortar product special admixture of the present embodiment includes the following formulation components in parts by weight,

[0156] In parts by weight, including the following formula components,

[0157] 5 parts of superplasticizer powder,

[0158] 30 parts of rubber powder,

[0159] 3 parts retarder,

[0160] Defoamer 2 parts,

[0161] 50 parts of stimulating agent.

[0162] Among the above-mentioned special admixtures for assembled mortar products,

[0163] The preparation method of described water reducing agent powder is as follows,

[0164]Prepare HPEG monomer, ammonium persulfate, bottom water, material A and material B, wherein the mass ratio between HPEG monomer, ammonium persulfate and water is 400:3:240, and material A includes acrylic acid, acrylamide, methyl The mass ratio between sodium propylene sulfonate and water, acrylic acid, acrylamide, sodium methacryl sulfonate and water is 36:10:5:70, wherein material B includes thioglyco...

PUM

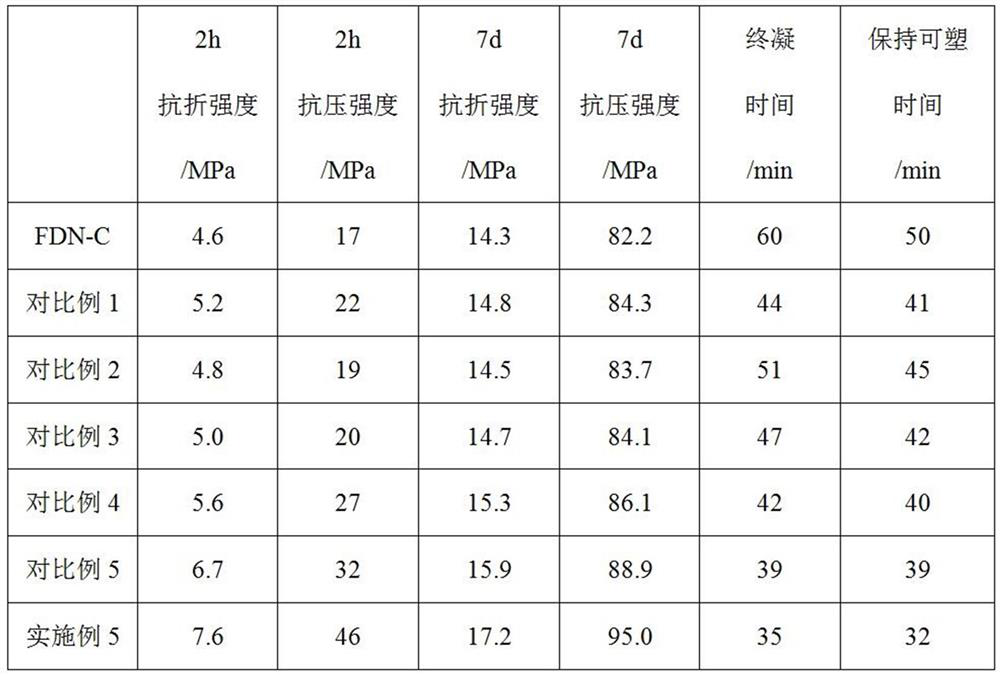

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com