Chelated multielement medium-trace-element spraying fertilizer and preparation method thereof

A technology for chelating trace elements and medium and trace elements, which is applied in the direction of organic fertilizers, inorganic fertilizers, fertilization devices, etc., can solve the problems of lack of medium and trace elements, crop impact, and lack of due attention, so as to promote synthesis and promote Effects on growth and promotion of mass reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

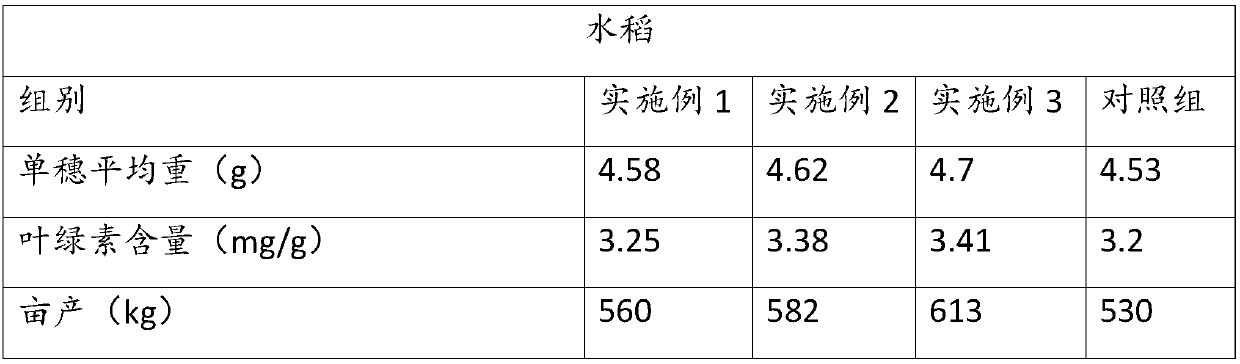

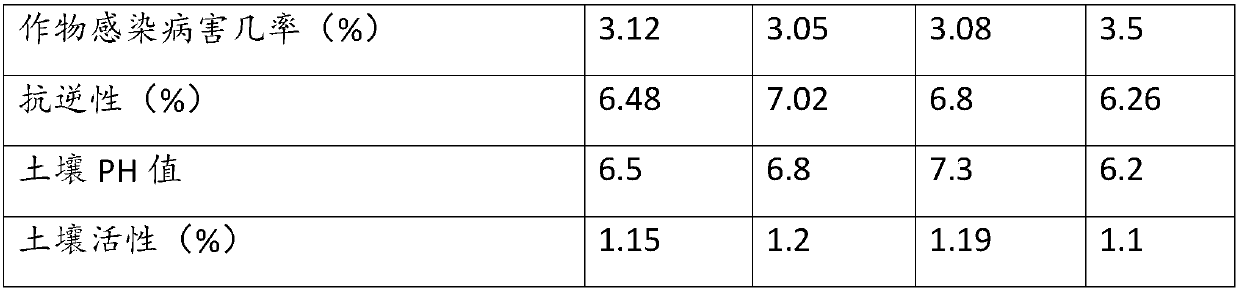

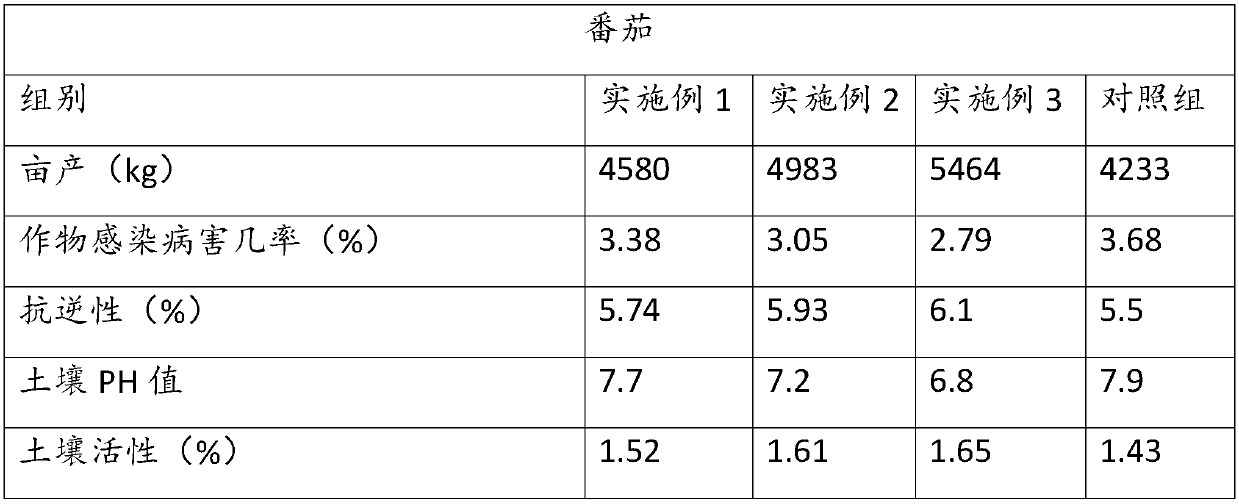

Embodiment 1

[0041] A chelated multi-trace element spraying fertilizer is characterized in that it is made of the following raw materials in parts by weight: 40 parts of EDTA chelated zinc, 40 parts of instant boron, 16 parts of EDTA chelated manganese, and compound EDTA chelated trace elements 32 parts, 19.2 parts of mineral source fulvic acid, 176 parts of magnesium sulfate monohydrate.

[0042] Described EDTA chelated zinc is prepared according to the following method:

[0043] (1) Add disodium EDTA, basic zinc carbonate and zinc nitrate hexahydrate to dissolve in water, heat up to 70° C., and filter out insoluble impurities after reacting for 1 hour; the disodium EDTA, basic zinc carbonate and The mol ratio of zinc nitrate hexahydrate is 1: 0.8: 0.2;

[0044](2) Concentrate the filtrate in step (1), centrifuge when a large amount of crystals appear, dry and grind the separated crystals to obtain the finished product EDTA chelated zinc.

[0045] Described EDTA chelated manganese is pr...

Embodiment 2

[0069] A chelated multi-component trace element spraying fertilizer is characterized in that it is made of the following raw materials in parts by weight: 50 parts of EDTA chelated zinc, 50 parts of instant boron, 20 parts of EDTA chelated manganese, and compound EDTA chelated trace elements 40 parts, 24 parts of mineral source fulvic acid, 220 parts of magnesium sulfate monohydrate.

[0070] Described EDTA chelated zinc is prepared according to the following method:

[0071] (1) Add disodium EDTA, basic zinc carbonate and zinc nitrate hexahydrate to dissolve in water, heat up to 70° C., and filter out insoluble impurities after reacting for 1 hour; the disodium EDTA, basic zinc carbonate and The mol ratio of zinc nitrate hexahydrate is 1: 0.8: 0.2;

[0072] (2) Concentrate the filtrate in step (1), centrifuge when a large amount of crystals appear, dry and grind the separated crystals to obtain the finished product EDTA chelated zinc.

[0073] Described EDTA chelated mangan...

Embodiment 3

[0097] A chelated multi-component trace element spraying fertilizer is characterized in that it is made of the following raw materials in parts by weight: 60 parts of EDTA chelated zinc, 60 parts of instant boron, 24 parts of EDTA chelated manganese, and compound EDTA chelated trace elements 48 parts, 28.8 parts of mineral source fulvic acid, 264 parts of magnesium sulfate monohydrate.

[0098] Described EDTA chelated zinc is prepared according to the following method:

[0099](1) Add disodium EDTA, basic zinc carbonate and zinc nitrate hexahydrate to dissolve in water, heat up to 70° C., and filter out insoluble impurities after reacting for 1 hour; the disodium EDTA, basic zinc carbonate and The mol ratio of zinc nitrate hexahydrate is 1: 0.8: 0.2;

[0100] (2) Concentrate the filtrate in step (1), centrifuge when a large amount of crystals appear, dry and grind the separated crystals to obtain the finished product EDTA chelated zinc.

[0101] Described EDTA chelated manga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com