Adhesive removing agent and adhesive removing method

A technology for glue and glue parts is applied in the field of degumming, which can solve the problems of lack of glue removal solution and glue removal method, damage to the letter resistance and damage of metal decorative parts, and achieve the effects of stable properties, low cost and simple process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

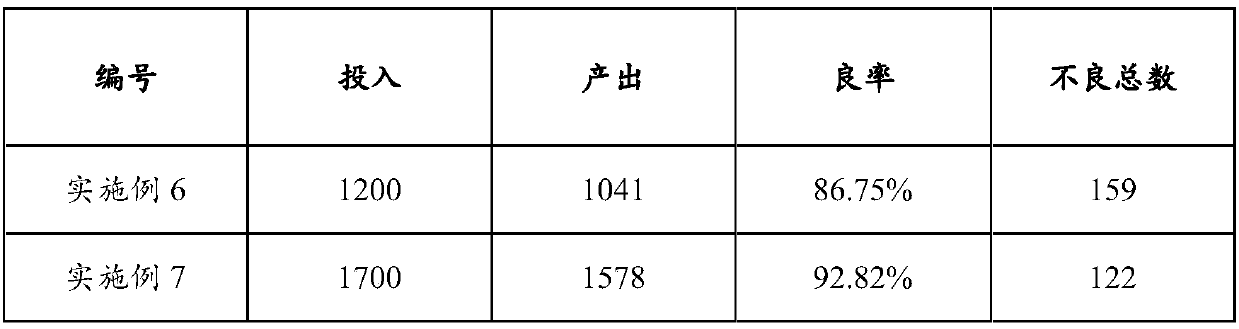

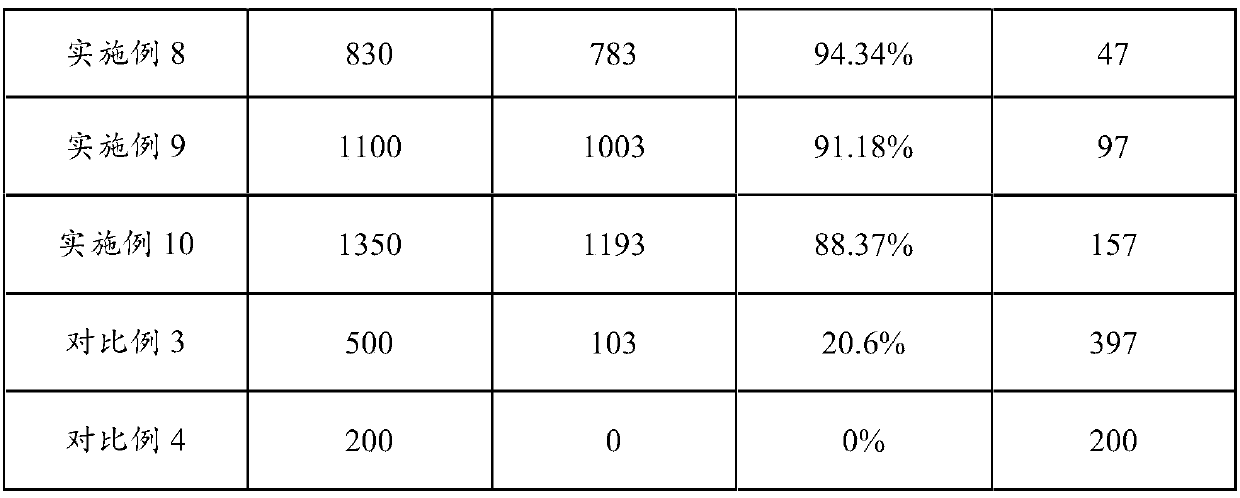

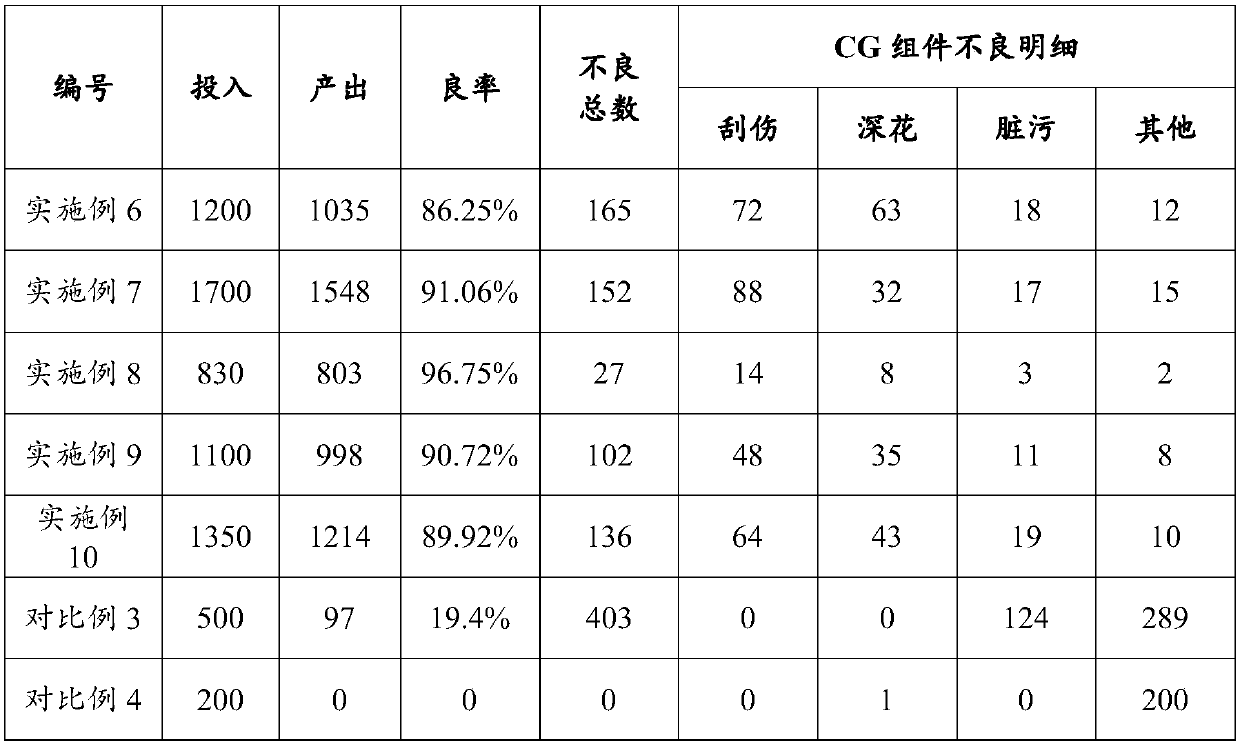

Examples

Embodiment 1

[0050] This embodiment is a glue remover, which includes 8% phytic acid, 7% sodium gluconate, 23% titanium dioxide and 62% additives by weight percentage.

Embodiment 2

[0052] This embodiment is a glue remover, which includes 10% phytic acid, 10% sodium gluconate, 25% titanium dioxide and 55% additives by weight percentage.

Embodiment 3

[0054] This embodiment is a glue remover, which includes 15% phytic acid, 10% sodium gluconate, 30% titanium dioxide and 45% additives by weight percentage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com