Method for looking for hole at bottom of filling drill hole

A technology at the bottom of the hole and in the borehole, which is applied in the fields of backfill, earthwork drilling, wellbore/well components, etc. It can solve the problems of easy wear and tear of pipelines in the hole and high safety hazards for construction personnel, and achieve high utilization rate and improved efficiency. Feasibility and efficiency, the effect of accelerating progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

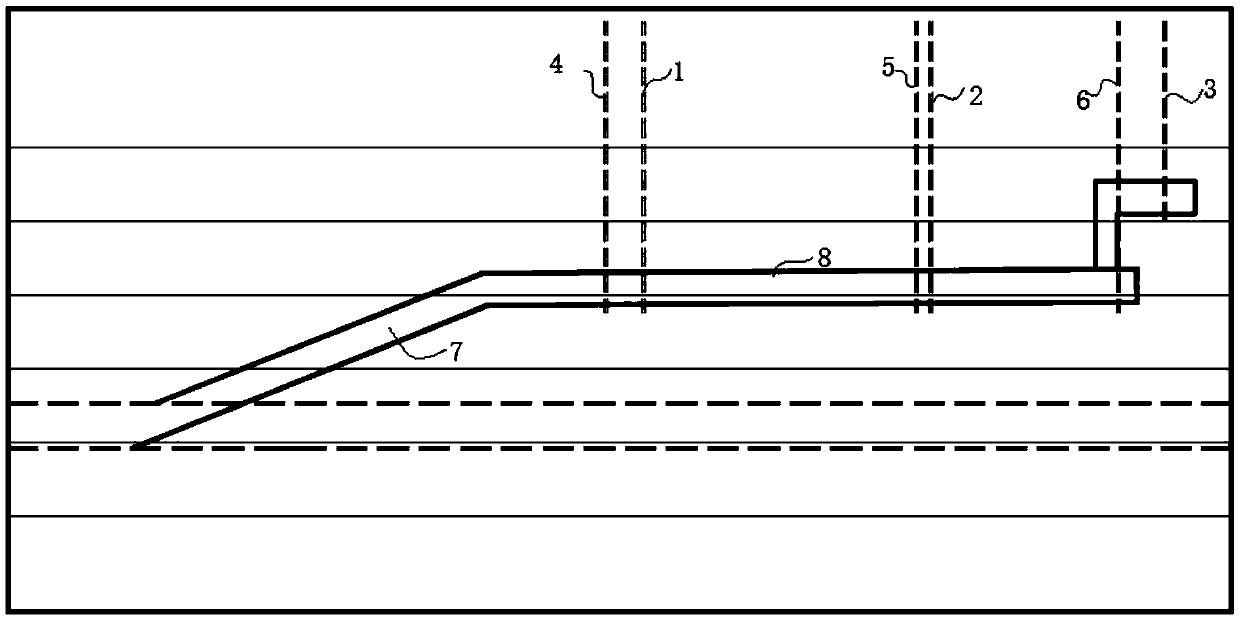

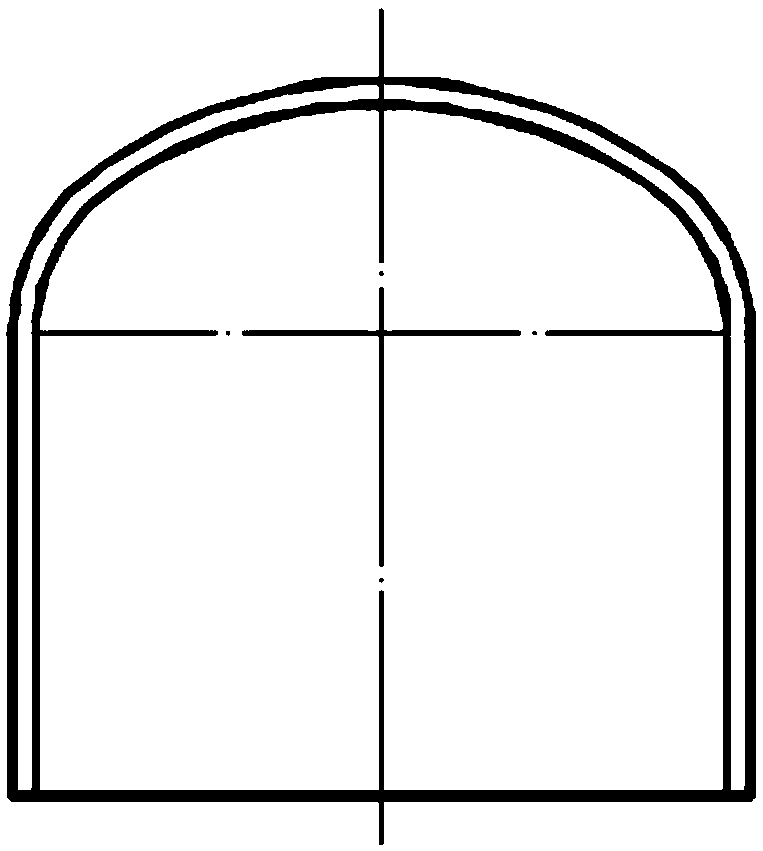

[0039] Such as figure 1 with figure 2 As shown, a method for finding holes at the bottom of a filling hole includes the following steps:

[0040] (1) Drill holes vertically from the filling station on the ground surface. In this embodiment, 6 holes are drilled, namely 1# hole 1, 2# hole 2, 3# hole 3, 4# hole 4, 5# hole 5 and 6# hole 6, drilled to the designed height below the ground surface, the height below the ground surface designed in this embodiment is -455m; after the drilling is completed, the hole is washed and cemented after the cement mortar wall. Bimetal composite wear-resistant pipes are installed in the borehole to prevent collapse and slabs around the borehole. Bimetal composite wear-resistant pipes are installed in all 6 holes, which effectively slows down the rubber material transportation to the downhole area. Wear to the hole, thereby increasing the service life of the hole;

[0041] (2) Construct a ramp 7 at the return air gate of 4# hole 4 at the height of -4...

Embodiment 2

[0049] Basically the same as embodiment 1, this embodiment also includes step (6): setting a steel structure protective wall, the steel structure protective wall is set at a distance of 1m from the filling borehole to be processed, if the distance is too close, the filling borehole pipe wall is The spray of high-pressure water in the pipeline after burning will cause damage to the construction personnel; the step (6) is set before the step (4). Preferably, the steel structure protective wall adopts I-steel beams to form the skeleton, The lap grid size is 110mmx110mm, and the skeleton is welded with 11mm thick steel plate as the surface layer, so that the overall steel structure protection wall has high strength and load-bearing capacity; the entire steel structure protection wall and the periphery of the roadway 8 are fixed by bolts. The surface of the rod body of the anchor rod is provided with a galvanized layer, and an operation observation hole is provided on the steel struc...

Embodiment 3

[0052] Basically the same as in embodiment 2, the difference from embodiment 2 is that the steel structure protective wall is set at a distance of 2m from the filling hole to be processed. If the distance is too far, the gas welding operator cannot perform remotely in the steel structure protective wall. Pipeline wall breaking operation; the steel structure protection wall adopts I-steel beam lap joint as the skeleton, the lap grid size is 100mmx100mm, and the skeleton is welded with 10mm thick steel plate as the surface layer, so that the overall steel structure protection wall has higher strength And load-bearing capacity; the entire steel structure protective wall and the periphery of the roadway 8 are fixed by bolts, the surface of the bolt body is provided with a galvanized layer, and the steel structure protective wall is provided with an operation observation hole. Preferably, the operation observation The size of the hole is 100mmx100mm, which satisfies the operating spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com