Integrated seal structure for high-temperature wear environment

A sealing structure and integrated technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of the original sealing wear-resistant plate falling off, improve the sealing effect, shorten the production cycle, and save manual cutting and sticking. The effect of the welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

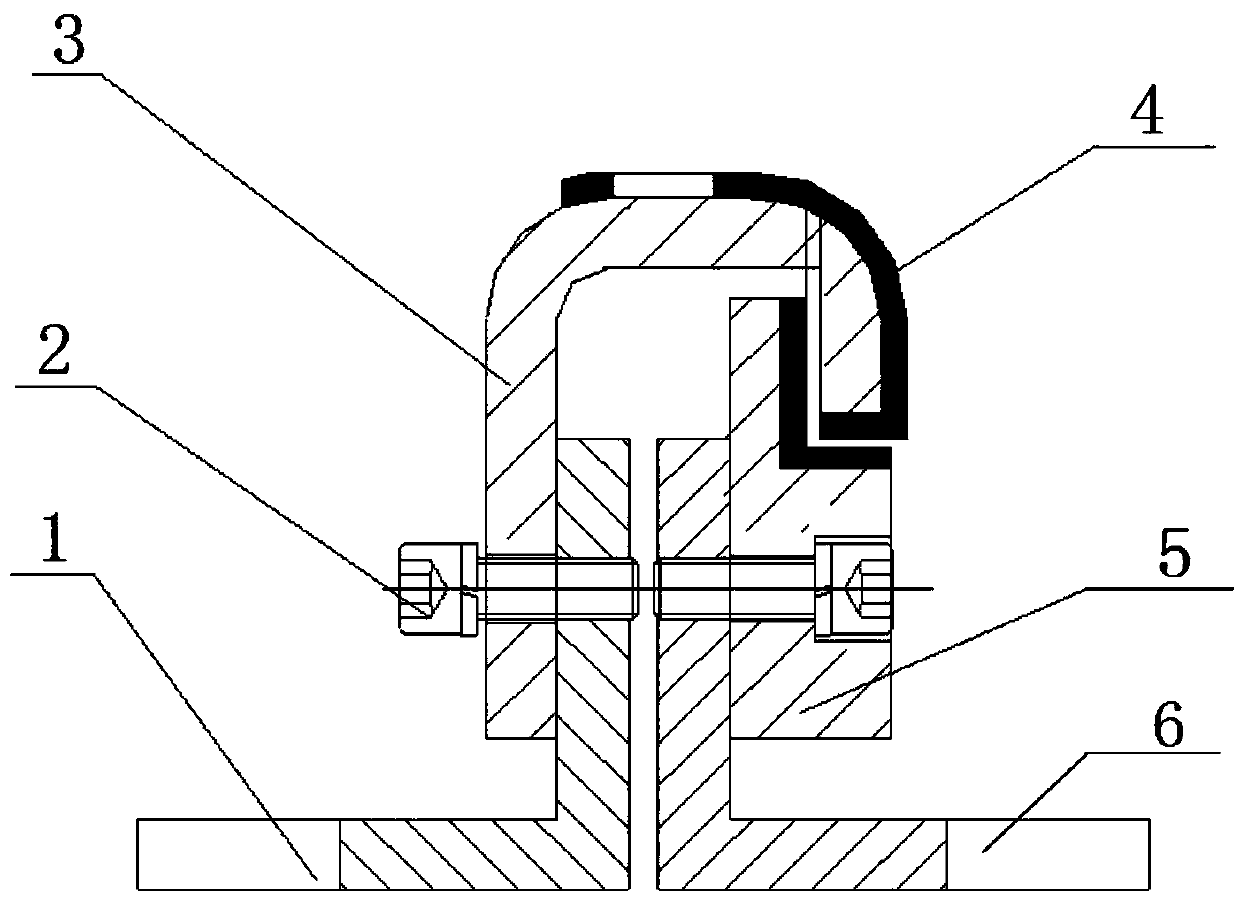

[0015] Such as figure 1 As shown, the integrated sealing structure for high-temperature wear environment of the present invention includes a left bracket 1, a right bracket 6, an outer seal 3 and an inner seal 5, and is suitable for high-temperature environments such as grate coolers and dryers.

[0016] The outer seal 3 and the inner seal 5 are installed and fixed on the left bracket 1 and the right bracket 6 respectively, and are connected by bolts 2 . The left bracket 1 and the right bracket 6 are arranged oppositely, and are fixedly mounted on positions that need to be sealed on equipment such as grate coolers and dryers. The outer seal 3 is a "J"-shaped plate integrally formed. The outer seal 3 and the inner seal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com