Energy-saving water heater with waste heat recycling function

An energy-saving water heater and waste heat recovery technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as skin irritation, waste heat from high-temperature exhaust gas, environmental pollution, etc., to avoid waste, reduce pollution, and effectively And the effect of rational use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

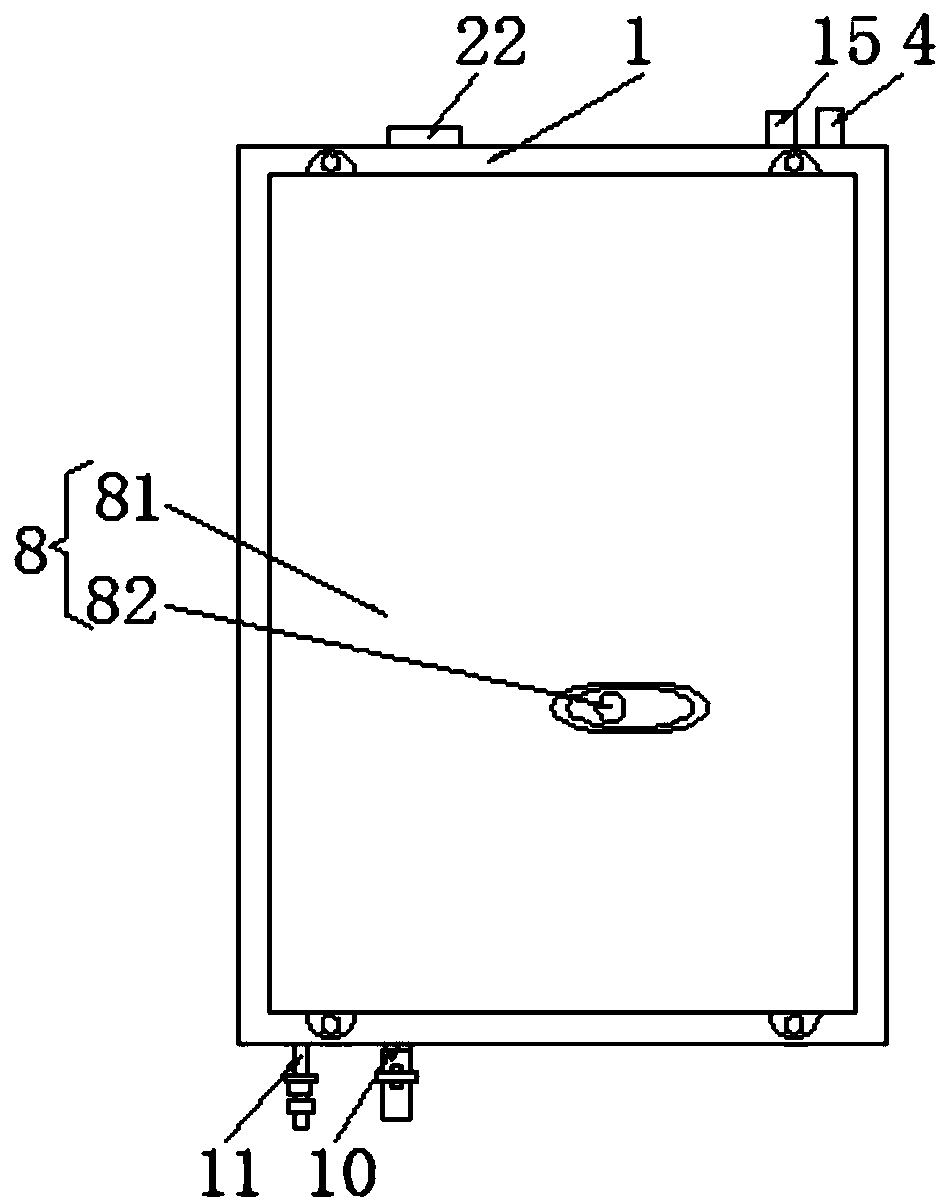

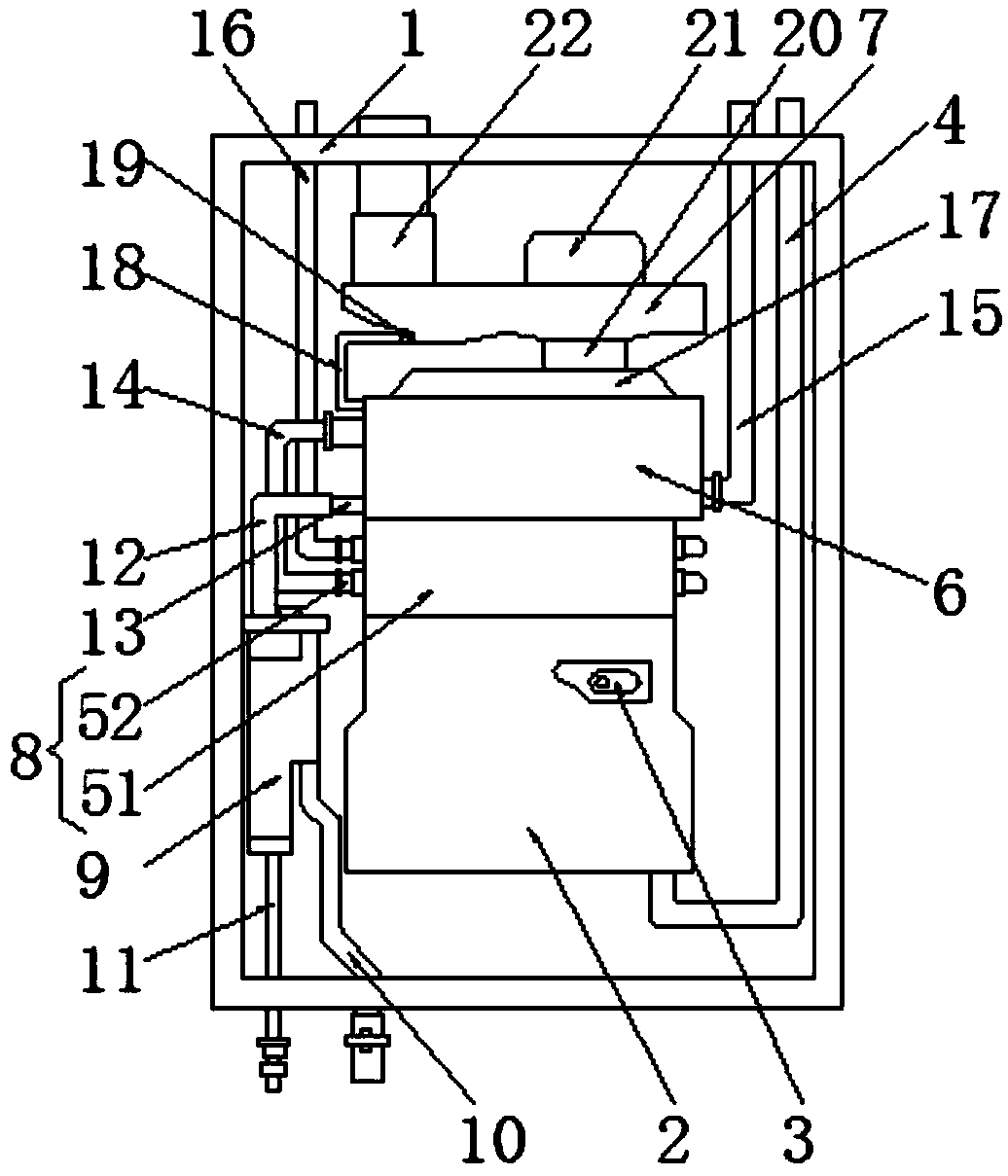

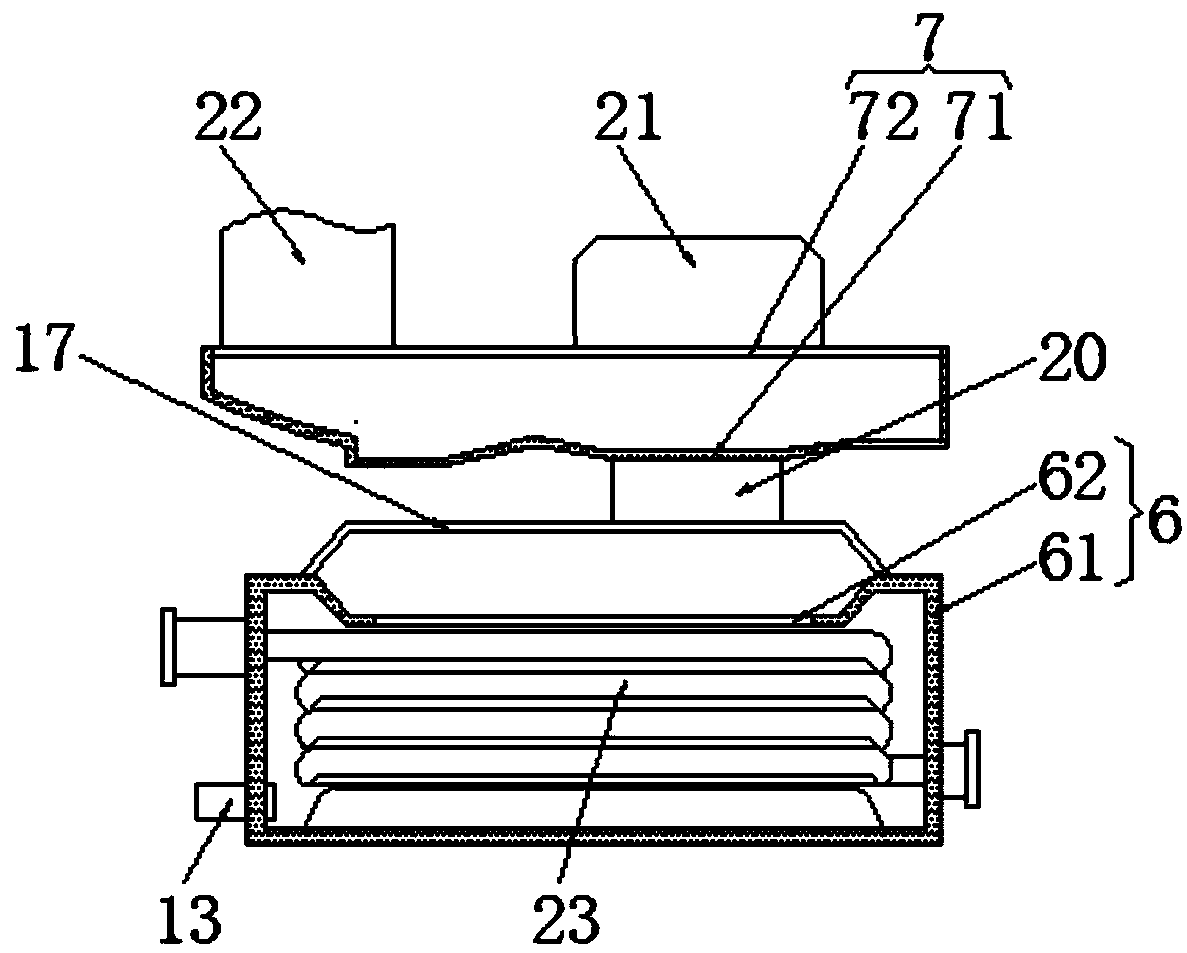

[0028] see Figure 1-4 , the present invention provides a technical solution: an energy-saving water heater with waste heat recovery, including a water heater shell 1, the front of the water heater shell 1 is fixedly connected with a protective assembly 8 through bolts, and a burner is provided inside the water heater shell 1 2, and the burner 2 is fixedly installed on the inner wall of the water heater shell 1, the burner 2 is fixedly connected with the inner wall of the water heater shell 1, and the outer wall of the burner 2 is fixedly installed with a spark plug 3, the burner 2 The top of the primary heat exchanger 5 is fixedly installed, and one end of the primary heat exchanger 5 communicates with the delivery pipe 16, and the primary heat exchanger 5 is fixedly connected with the delivery pipe 16, and the primary heat exchanger 5 The other end is fixedly connected to the secondary heat exchanger 6 through the first connecting pipe 14, and the outer wall of the secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com