Low-voltage wire connector

A wire joint, low-voltage technology, applied in the field of electric power, can solve problems such as unfitness, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

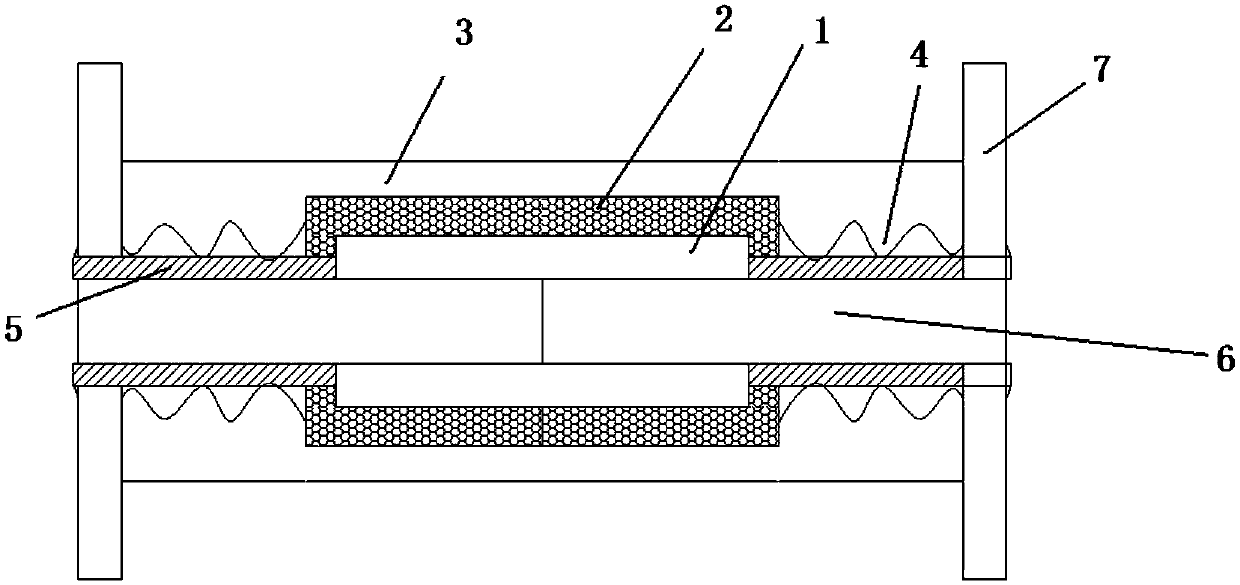

[0009] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, the present invention includes a conductive sleeve 1, an insulating sleeve 2 is provided on the outside of the conductive sleeve 1, and a compression sleeve 3 is provided on the outside of the insulation sleeve 2; press buckles 4 are provided on both sides of the compression sleeve 3, so that The press buckle 4 corresponds to the wire sheath 5, and the conductive core 6 of the wire corresponds to the conductive sleeve 1; positioning rings 7 are arranged on both sides of the compression sleeve 3.

[0010] There are a plurality of press buttons 4 arranged evenly.

[0011] When in use, after inserting the two sections of wires into the quick-change joint, use calipers to press the compression sleeve tightly. Since the compression sleeve is generally made of soft metal, such as aluminum and copper, the outer skin of the wire is pressed and clamped. Therefore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com