Modified natural graphite lithium ionic cell cathode material, manufacturing method thereof and application

A lithium-ion battery and natural graphite technology, which is applied in the field of modified natural graphite lithium-ion battery anode materials and its manufacturing, can solve the problems of reduced initial efficiency, increased irreversible capacity, and large specific surface area

Inactive Publication Date: 2010-11-24

新乡市华鑫电源材料有限公司

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the large specific surface area due to the nanoscale pores or cracks on the surface, it will still cause an increase in irreversible capacity and a decrease in the first efficiency.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

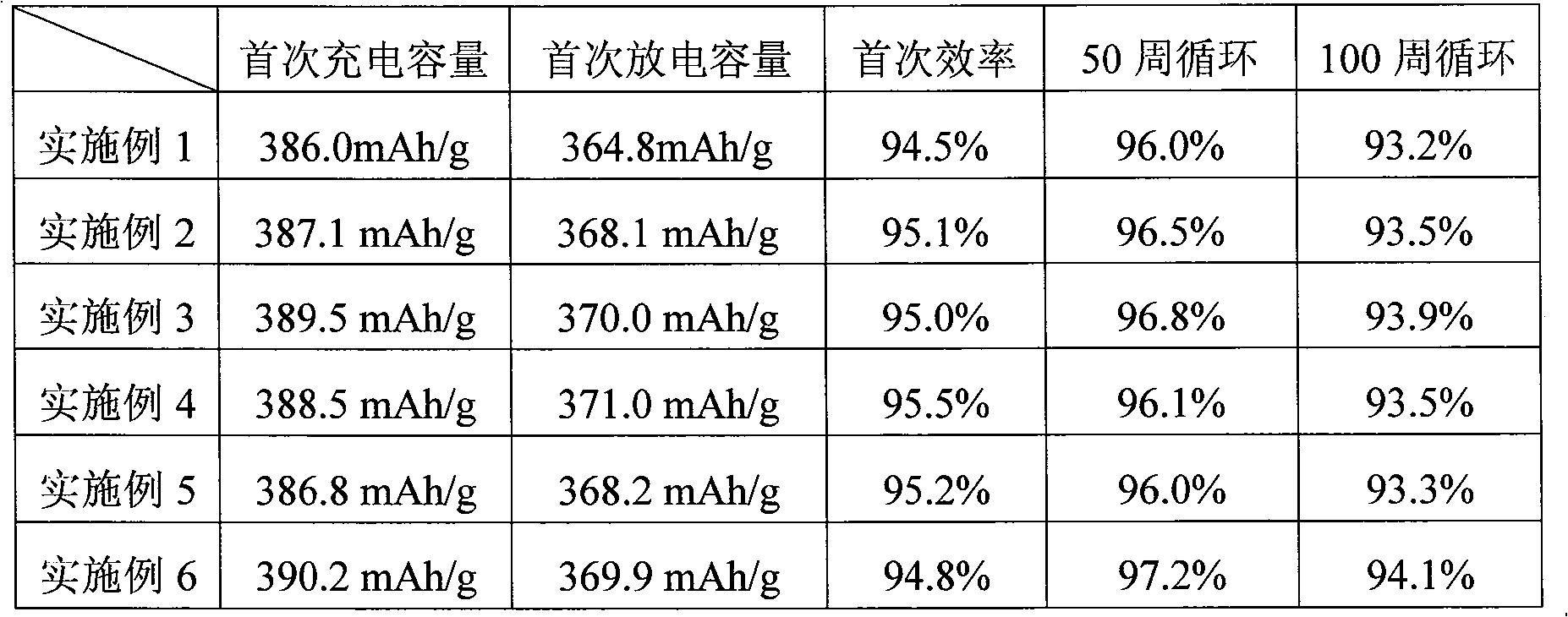

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a cathode material of modified natural graphitic lithium ion batteries. The material comprises ball natural graphite with a fixed carbon content over 90 percent, asphalt for coating a transitional vector and nano-pore superconducting graphite, and the weight ration of constituents of the three raw materials is 10: 0.1 to 2.0: 0.1 to 2.0. The cathode material of modified natural graphitic lithium ion batteries is used for manufacturing the lithium ion battery, which is characterized in that the nano-pore superconducting graphite is added in the coating process. The nano-pore superconducting graphite can not modify the property of the raw materials, but can significantly improve the conductivity of the raw materials, without adding with any conductive agent in the application in later stage. And the nano-pore superconducting graphic can be well compatible with an electrolyte and improve the reversible capacity of the materials.

Description

Modified natural graphite lithium ion battery negative electrode material and its manufacturing method and application technical field The invention relates to a negative electrode material for a lithium ion battery and a manufacturing method thereof, in particular to a modified natural graphite lithium ion battery negative electrode material, a manufacturing method and an application thereof. Background technique At present, as a green chemical power source, lithium-ion batteries have incomparable advantages of high voltage, long life, and high energy density compared with traditional lead-acid batteries, nickel-hydrogen batteries, and nickel-cadmium batteries. Since the advent of the first generation of lithium-ion batteries, their anode materials have always been the focus and hotspot of energy material research, and have attracted the attention of many scholars. Later, people thought that the specific capacity of graphite was very limited, so they began to study other ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M4/02H01M4/04H01M4/38H01M4/62

CPCY02E60/10

Inventor 李文漫叶涛赵林治谢封超

Owner 新乡市华鑫电源材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com