Reclaimed water reuse device

A technology of reclaimed water and reverse osmosis equipment, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc. High operating costs for sewage treatment, etc., to achieve good effluent quality, flexible and stable operation, and a wide range of system applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

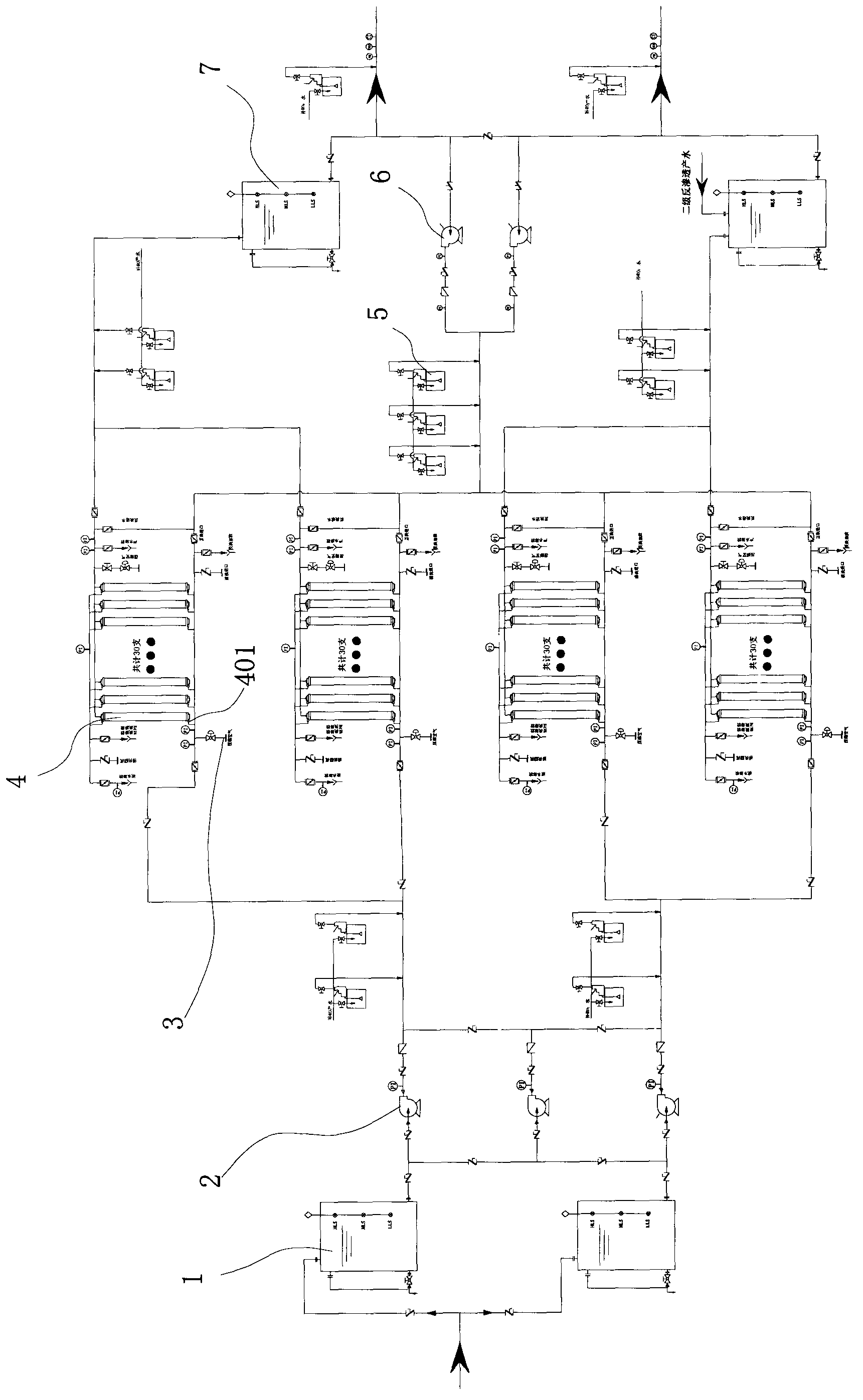

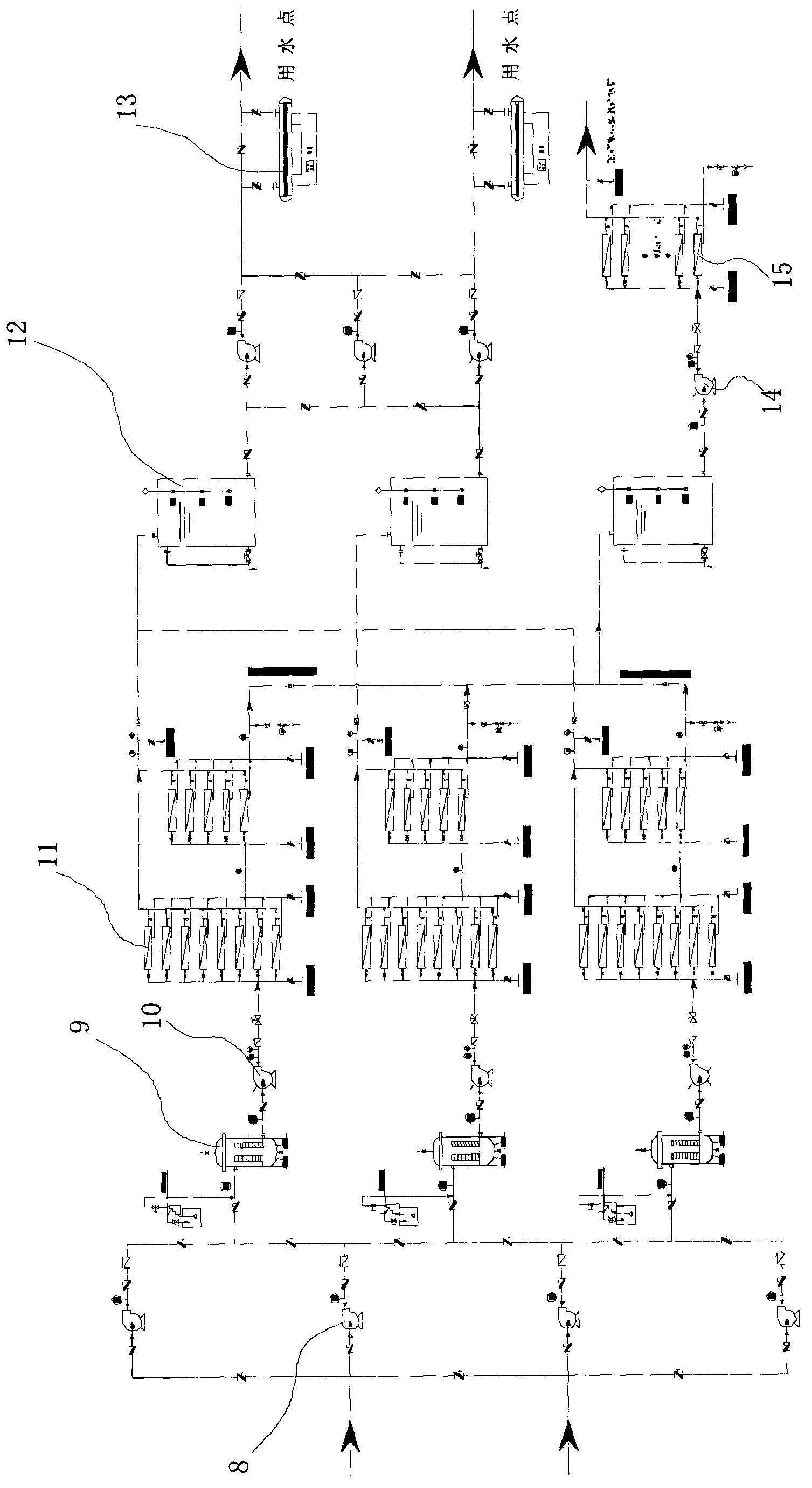

[0018] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0019] Such as figure 1 and figure 2 , a reclaimed water reuse device, which includes a collection tank 1 for collecting waste water, the collection tank 1 is connected to the water production tank 7 through a raw water pump 2 (frequency conversion), a tubular membrane device 4, and a tubular membrane device 4 A pressure port 401 whose flow rate is twice the flow rate in the tubular membrane device is set at the inlet of the tube; the tubular membrane device 4 is provided with backwashing equipment, and the backwashing equipment includes a backwashing water pump 6 and a dosing device 5 connected in sequence, The backwash water of the tubular membrane comes from the tubular membrane water production tank 7; the water production tank 7 is connected to freshwater pool12. An air compression pump (not shown) is also connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com