Production method of plasticiser capable of improving cigarette filter stick filtering effectiveness and suction quality

A technology of filtration efficiency and suction quality, applied in e-liquid filter elements, tobacco, food science, etc., to achieve the effects of good stability, improved suction quality, and excellent biological safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

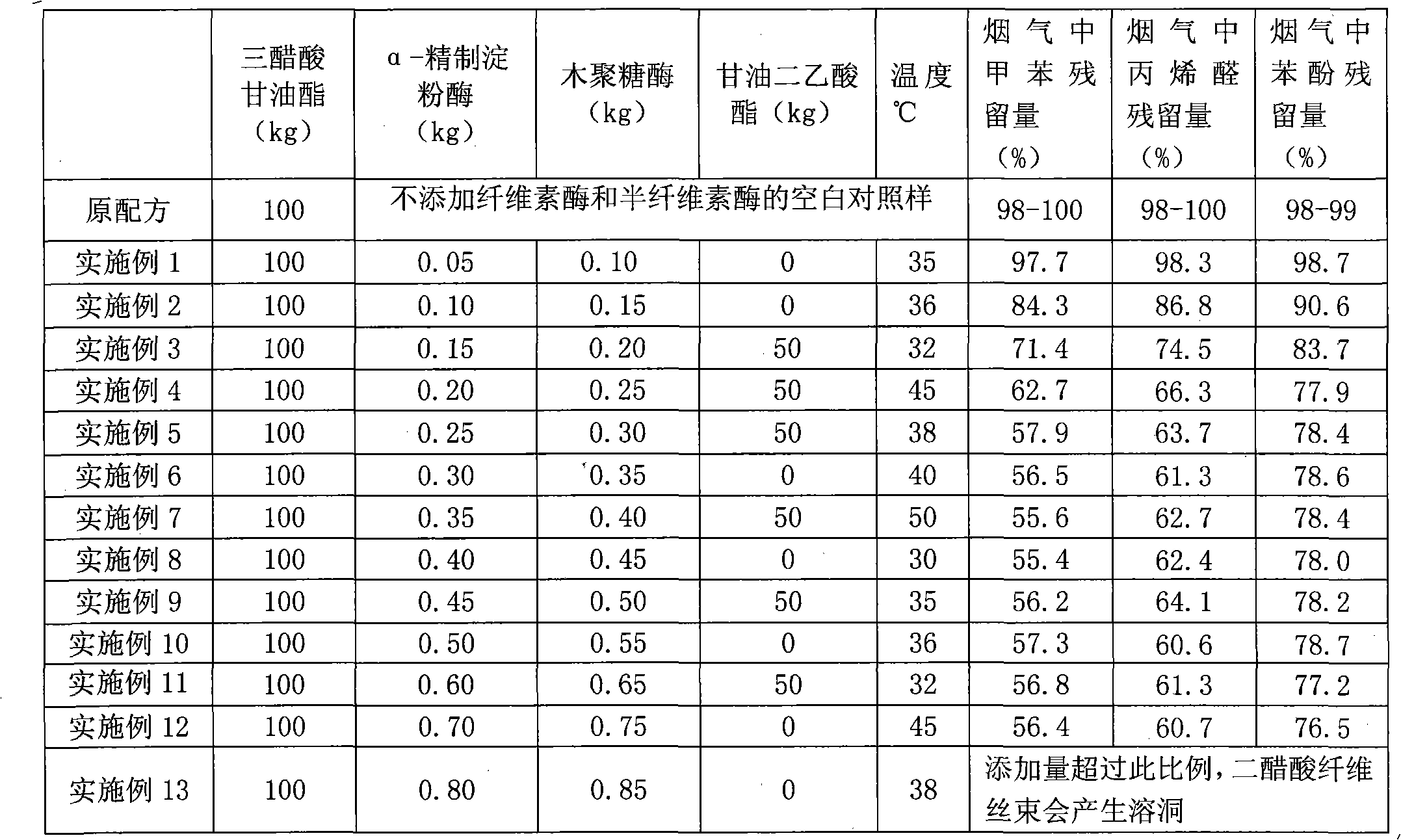

Embodiment 1~ Embodiment 13

[0020] In Examples 1 to 13, the raw materials used: 1. triacetin; 2. cellulase: α-refined amylase; 3. hemicellulase: xylanase, and the specific steps are as follows:

[0021] A heat triacetin, add α-refinement amylase and xylanase in triacetin;

[0022] B temperature is kept at 30-50°C, and the mixture is stirred so that the α-refined amylase and xylanase are fully dissolved in triacetin and evenly distributed;

[0023] C Stop stirring, and observe after the air bubbles dissipate. If the mixture is clear and free of particles and other small impurities, stop the heat preservation and cool to room temperature.

[0024] In order to speed up the production speed, the α-refined amylase and xylanase can be dissolved in diacetin before step A, and then added to glycerol triacetate, and then operated according to steps A-C.

[0025] The proportions of α-refined amylase and xylanase in Examples 1 to 13 are different, and the specific implementation steps are also different. In some e...

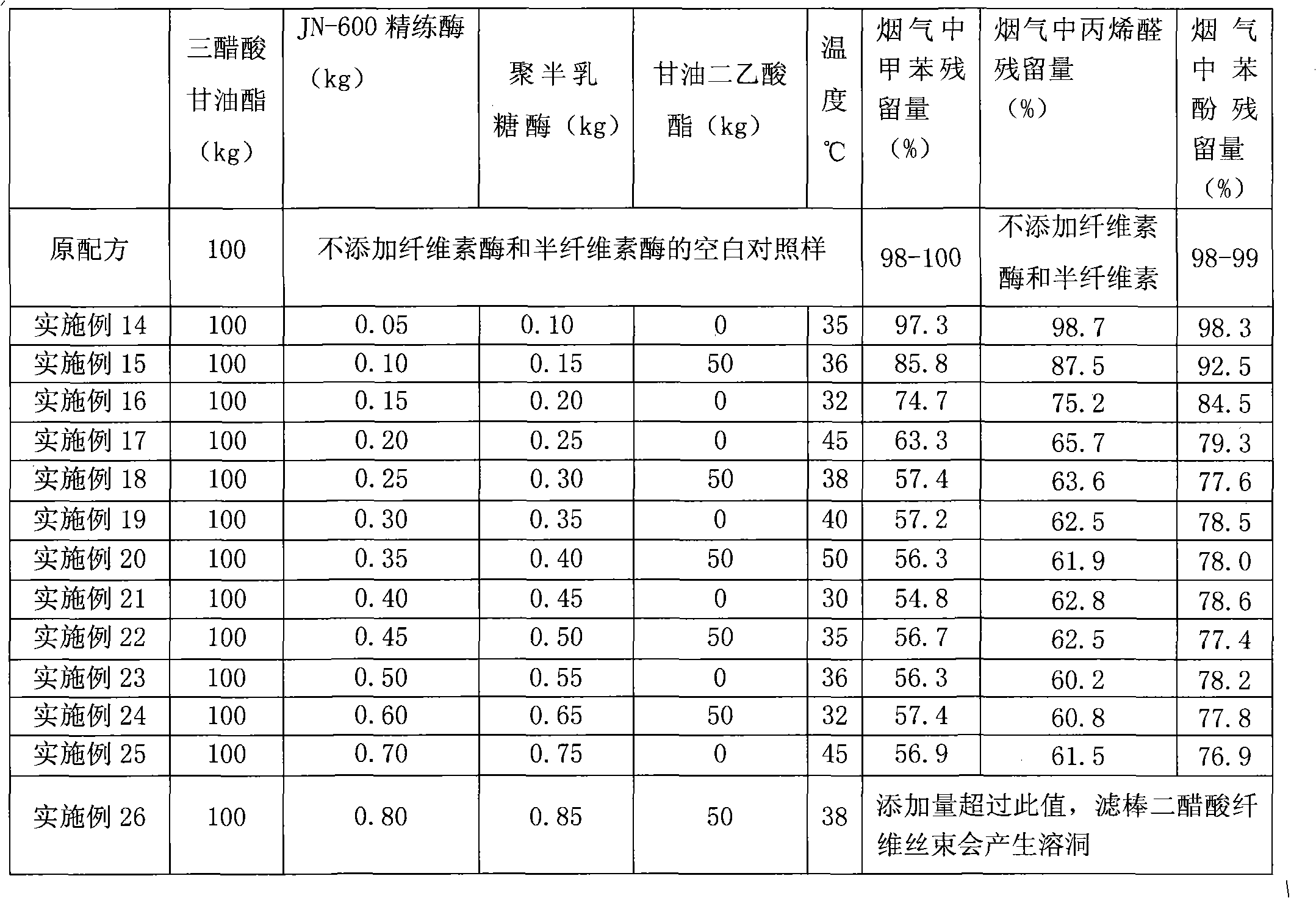

Embodiment 14~ Embodiment 26

[0030]The specific implementation method is the same as in Example 1 to Example 13, except that the cellulase used is JN-600 scouring enzyme, and the hemicellulase is polygalactase.

[0031] In Example 14 to Example 26, the addition ratio of cellulase and hemicellulase is different, and the effect of the produced product is not the same after being used in a filter rod. The contents of aldehydes, benzenes, and phenols in cigarette smoke are all different. Calculated as 100%, the specific test results are shown in Table 2.

[0032] The test results show that as long as JN-600 scouring enzyme and polygalactase are added to triacetin, even a small amount, it can reduce harmful components such as aldehydes, benzenes, and phenols in cigarette smoke. If the amount added is small, the reduction effect on harmful components is not obvious, but if the amount added is too large, JN-600 scouring enzyme and polygalactase will dissolve the diacetate fiber tow and form caves in the filter r...

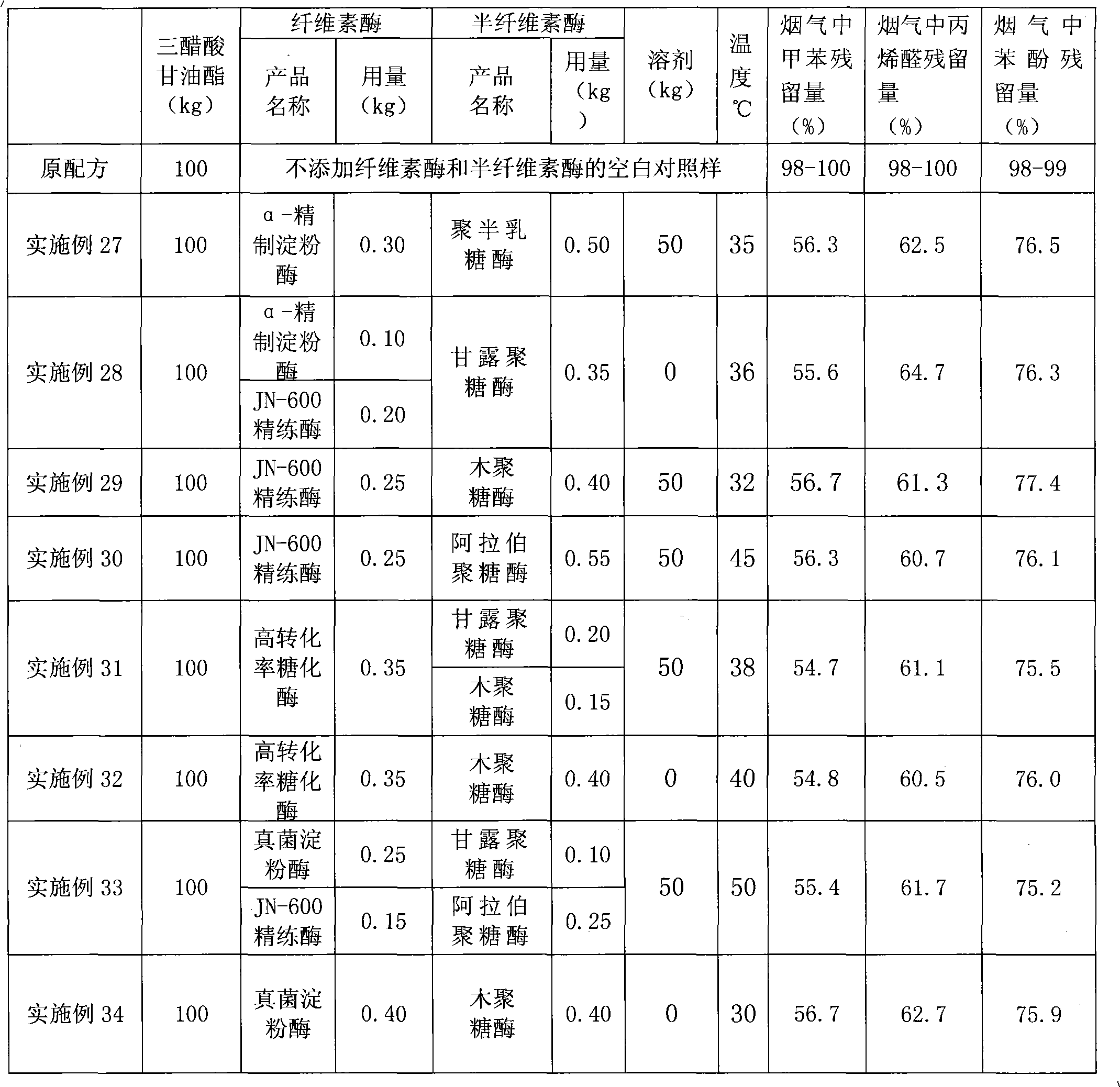

Embodiment 27~ Embodiment 34

[0036] In Examples 27 to 34, the raw materials used are: glycerol triacetate, and the cellulase is one of α-refined amylase, JN-600 scouring enzyme, high-conversion glucoamylase, and fungal amylase; The cellulase is one of xylanase, polygalactosidase, arabinase, and mannanase, and the specific implementation method is the same as in Example 1-Example 26. In Examples 27 to 34, the addition ratio of cellulase and hemicellulase is different, and the effect of the produced products after being used in filter rods is also different. The contents of aldehydes, benzenes, and phenols in cigarette smoke are all different. Calculated as 100%, the specific test results are shown in Table 3.

[0037] The test results show that no matter what the source of cellulase and hemicellulase is, as long as they are added to triacetin, after the treatment of cigarette filter rods, they will have no effect on harmful components such as aldehydes, benzenes, and phenols in cigarette smoke. There is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com