Sausage stuffer for stuffing sweet potato starch casing

A technology of sweet potato starch and sausage filling machine, which is applied in the field of food processing, can solve the problems of poor taste, no innovation and breakthrough, and waste of sweet potatoes, and achieve the effects of improving taste, improving production efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

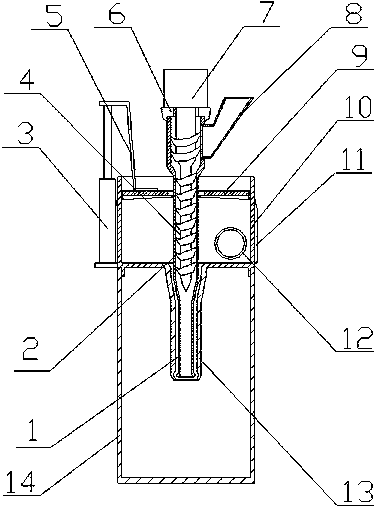

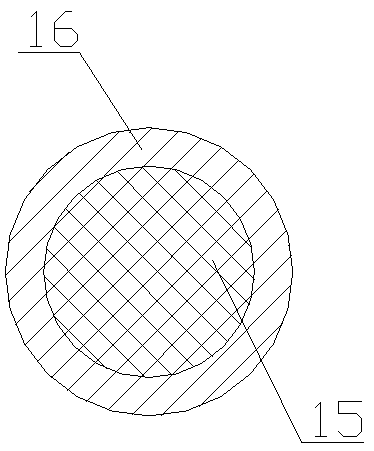

[0027] A sausage enema machine for sweet potato starch casing enema of the present invention is realized in the following way: a sausage enema machine for sweet potato starch casing enema of the present invention is composed of an inner guide pipe (1), a connecting pipe (2), a pneumatic cylinder (3), and a screw shaft (4), connecting rod (5), motor base (6), drive motor (7), feeding tube (8), extrusion plate (9), main body box (10), heating jacket (11), feeding tube (12), the outer material guide pipe (13) and the cooling cylinder (14), the main body box (10) is placed on the top of the cooling cylinder (14), the top of the cooling cylinder (14) is an open structure, the main body box (10) There is a plug-in plate at the bottom, and it fits the inner wall of the cooling tube (14). There is a guide hole in the middle of the bottom of the main body box (10). The diameter of the guide hole decreases gradually from top to bottom. The material guide tube (13) is placed in the cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com