FPGA based descaling system of ultrasonic guided-wave liquid-filled pipe

An ultrasonic guided wave and pipeline technology, applied in the direction of using vibrating fluids, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as excessive local pressure, waste of solution and water resources, limited coverage, etc., to achieve Prevents the generation of dirt, prevents the generation of dirt, and has a wide coverage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Further explanation will be given below in conjunction with the examples and accompanying drawings. The following examples are only descriptive language and not restrictive language, and cannot be used as a basis to limit the protection scope of the present invention.

[0032] The present invention is a system of descaling system of ultrasonic guided wave liquid-filled pipeline based on FPGA. The main idea is to combine the development of PFGA with the descaling of ultrasonic guided wave. With the advantages of wide coverage, long transmission distance, and no impact on normal production, it can meet the purpose of efficient, fast and safe removal of dirt.

[0033] The specific experimental steps are as follows:

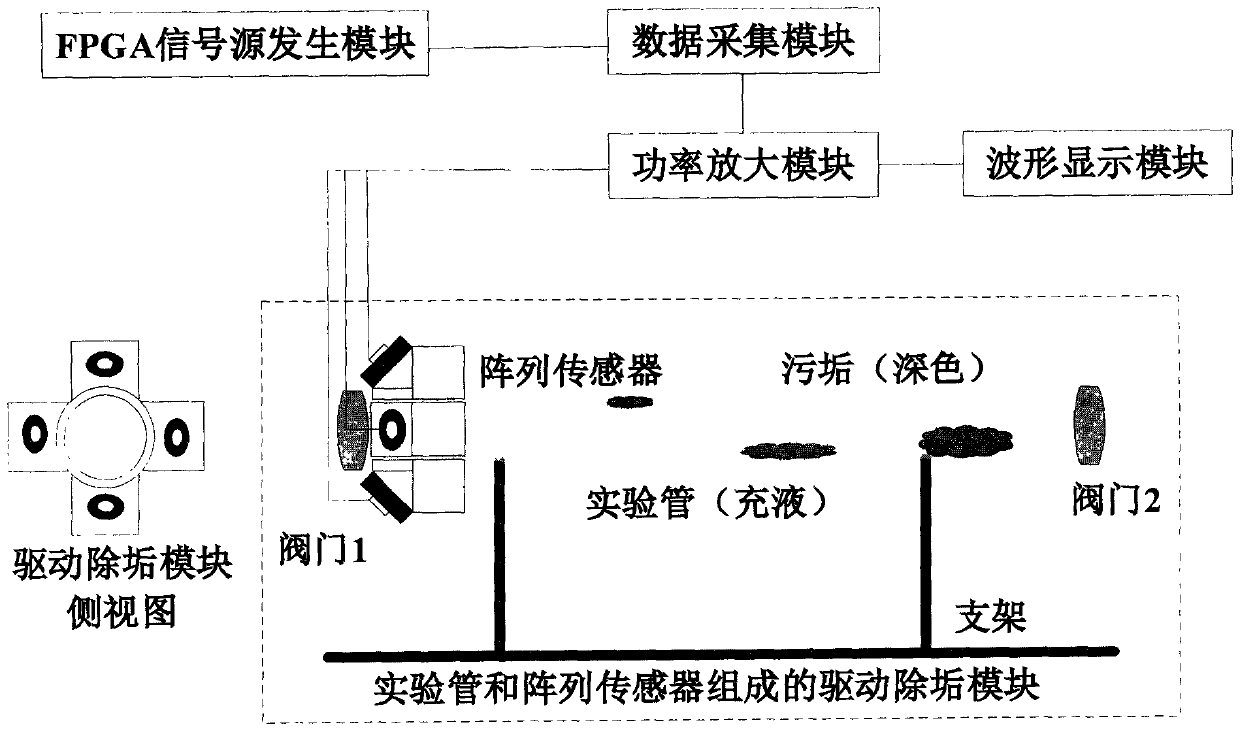

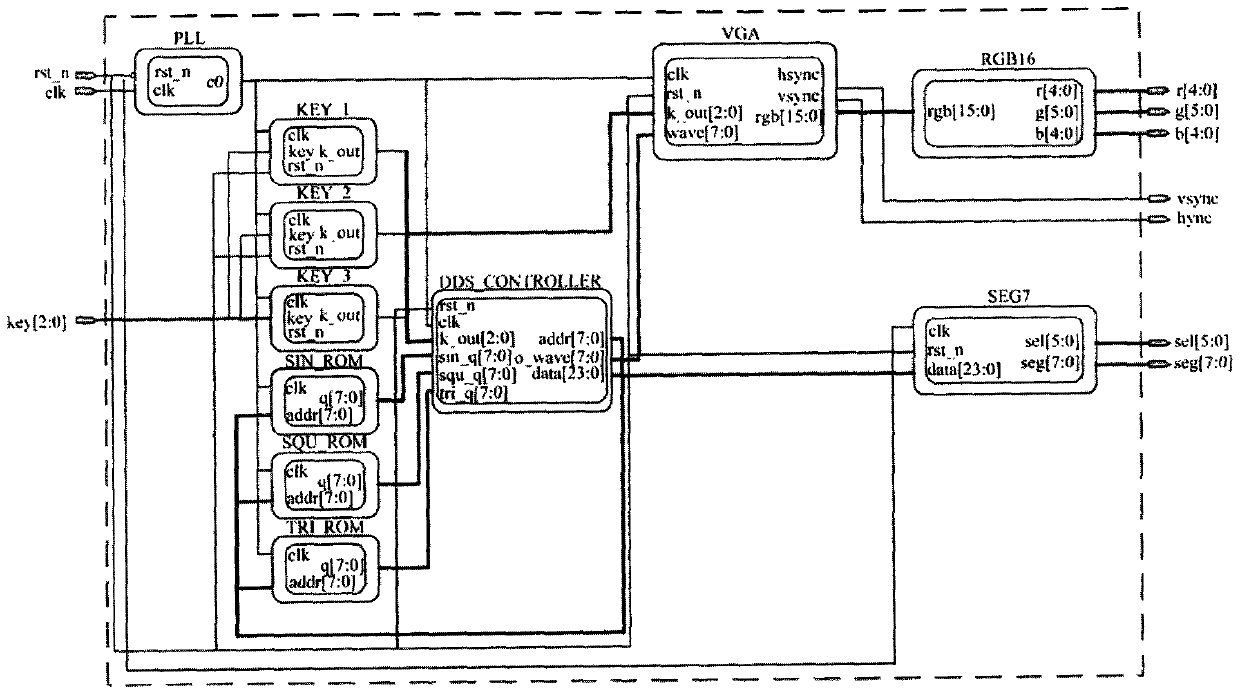

[0034] (1) A descaling system based on FPGA-based ultrasonic guided wave liquid-filled pipeline, such as figure 1 It is a schematic diagram of the system, mainly including signal source generation, data acquisition, power amplification, waveform display and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com