Spindle system cooling jacket and spindle system

A technology of cooling jacket and main shaft sleeve, which is applied in the directions of large fixed members, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of large pressure loss of coolant flow and low heat dissipation efficiency of cooling structure, and achieve high heat dissipation efficiency, The effect of reducing flow pressure loss and reducing flow length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

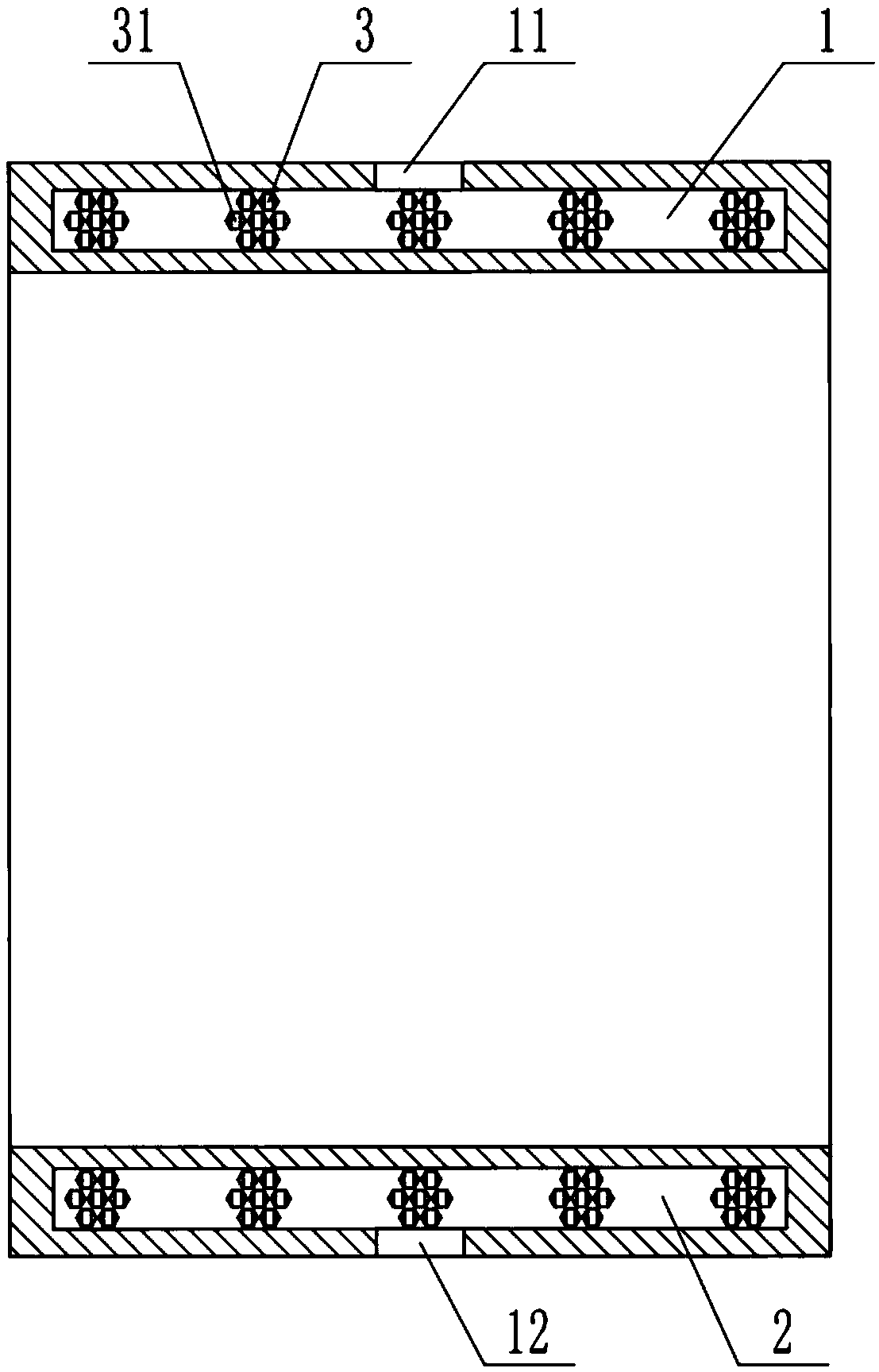

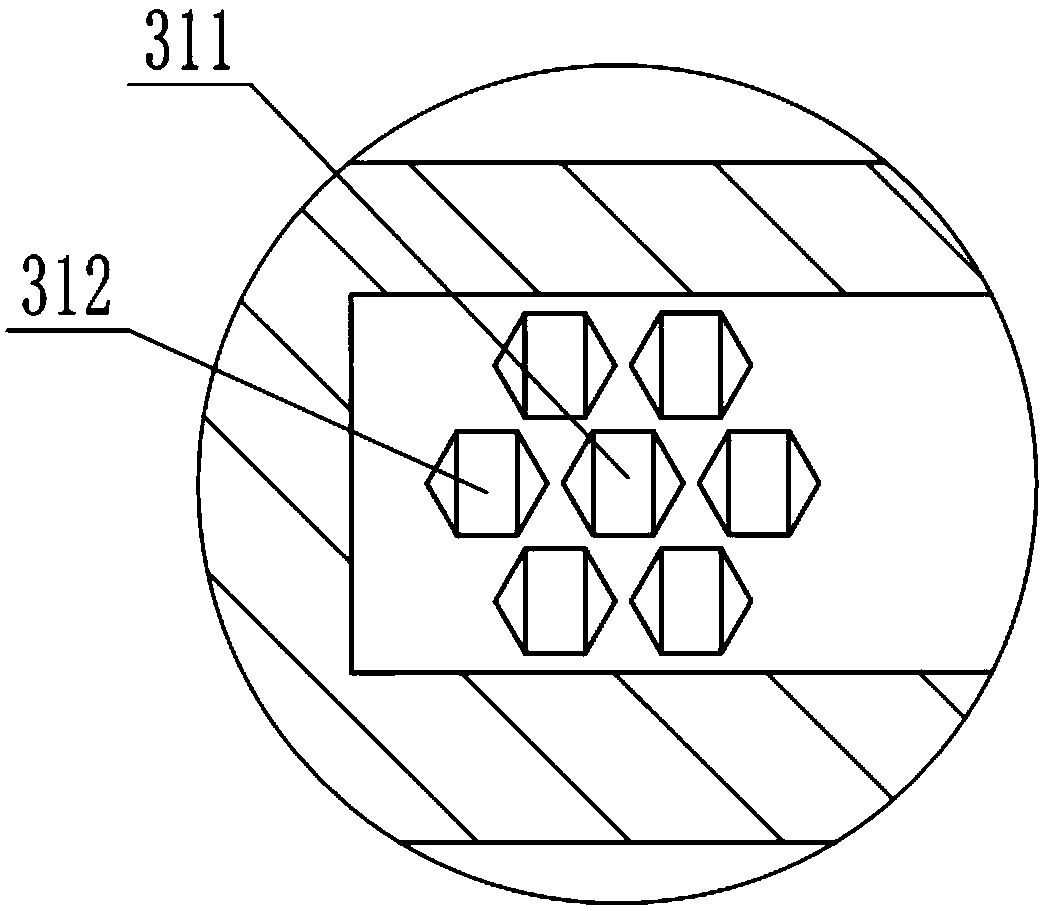

[0040] According to an embodiment of the present invention, the cross-section of the cooling channel 31 includes a circle and a polygon. When the perimeter of the section is constant, adopting a cooling channel 31 with a circular cross-sectional area can accommodate more cooling liquid and improve the cooling effect; adopting a cooling channel 31 with a polygonal cross-sectional area can make the gap between the cooling channels 31 Closely arranged to improve heat transfer efficiency, thereby improving cooling effect.

[0041] In the above, in order to reduce the area between the cooling channels 31 , the cross-section of the cooling channels 31 is a regular hexagon. A honeycomb structure is the best topology to cover a two-dimensional plane. Preferably, the cooling channel group 3 is a honeycomb bionic channel. That is, the regular hexagonal cooling channels 31 are arranged in a honeycomb structure.

[0042] In order to reduce the temperature difference of the casing, mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com