Vibration device for stirrer

A vibrating device, mixer technology, applied in the direction of cement mixing device, fluid using vibration, clay preparation device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

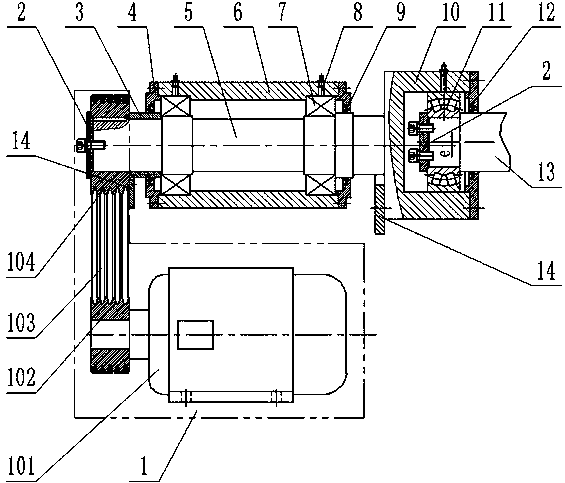

Embodiment 1

[0059] A vibration device for a mixer, comprising a vibration transmission device 1, a transmission shaft 5, a bearing I7, a bearing seat I6, a bearing II11, a bearing seat II10, and a stirring shaft 13. The transmission shaft 5 is a stepped shaft and is set through the bearing seat I6, and is supported and installed in the bearing seat I6 by two bearings I7. Bearing end covers 4 are respectively arranged at both ends of the bearing seat I6. On the bearing seat I6 Two lubricating oil passages 8 are provided, and the lubricating oil passages 8 respectively communicate with the oil passages of the outer ring of the bearing I7 for lubricating the bearing I7. The power source of the vibration transmission device 1 is a motor 101, a driving pulley 102 is installed on the output shaft of the motor 101, a driven pulley 104 is installed at one end of the transmission shaft 5, and a shaft end retaining ring is arranged at the end of the driven pulley 104 2. A positioning sleeve 3 is ar...

Embodiment 2

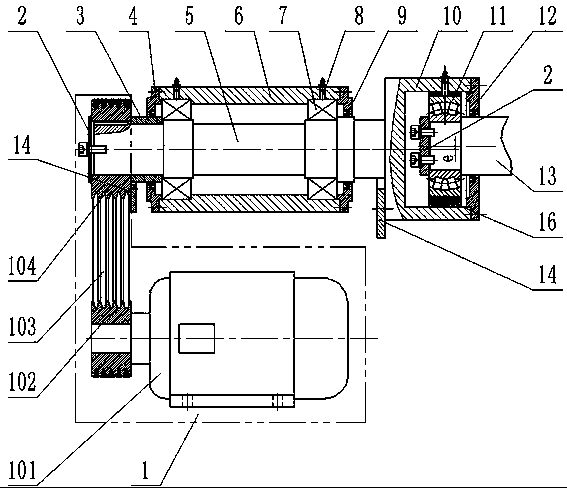

[0062] The difference from Example 1 is that an eccentric sleeve 16 is provided between the bearing seat II10 and the outer ring of the bearing II11, and the eccentric sleeve 16 can be a multi-shaft segment sleeve part, and the preferred single-shaft segment eccentric sleeve 16 is used for installation The centerline of the inner hole of the bearing II11 is eccentrically set relative to the centerline of rotation of the transmission shaft 5 , so that the centerline of rotation of the transmission shaft 5 is offset from the axis of the outer raceway of the bearing II11 .

Embodiment 3

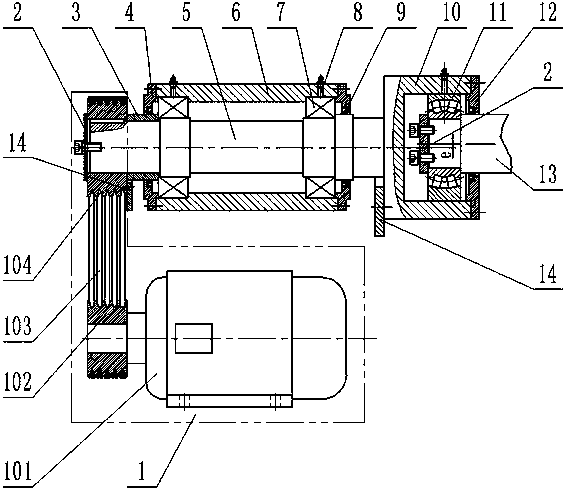

[0064]The difference from Example 1 is that the bearing II11 is an eccentric bearing of the outer ring, and the eccentric bearing of the outer ring refers to a bearing in which the center line of the outer circle of the outer ring is eccentric to the axis of the outer raceway, and the axis of the outer raceway It refers to the centerline of the outer raceway along the axial direction of the transmission shaft 5, so that the rotation centerline of the transmission shaft 5 is offset from the axis of the outer raceway of the bearing II11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com