Conveying steering crawler

The technology of crawler belt and crawler shoe is applied in the field of food processing equipment, which can solve the problems of energy waste and increase the floor space of the conveying device, and achieve the effects of avoiding falling objects, simple structure and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

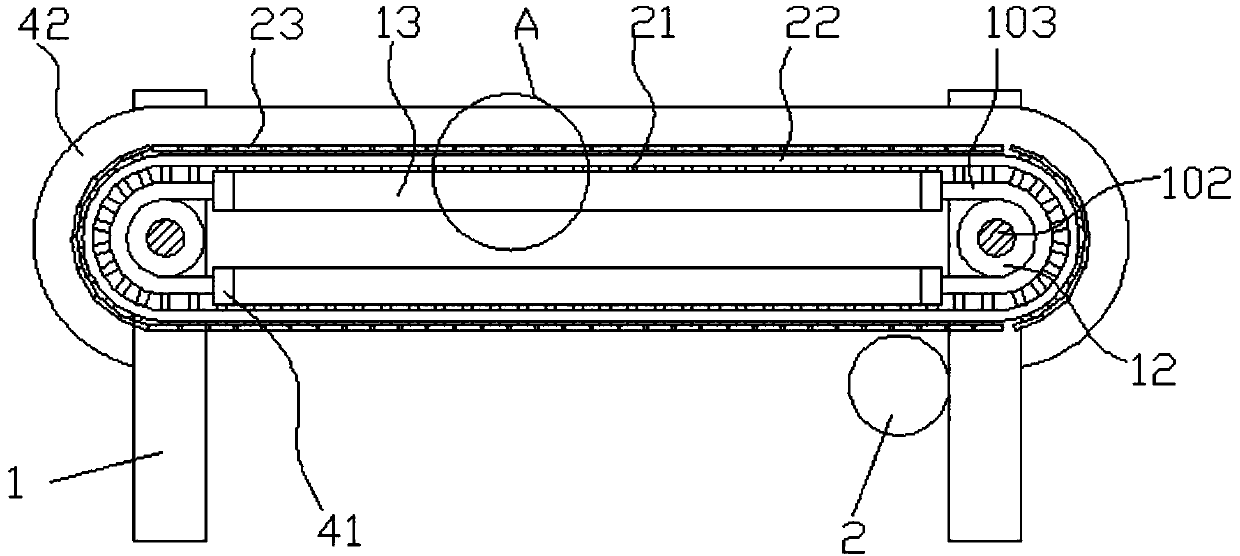

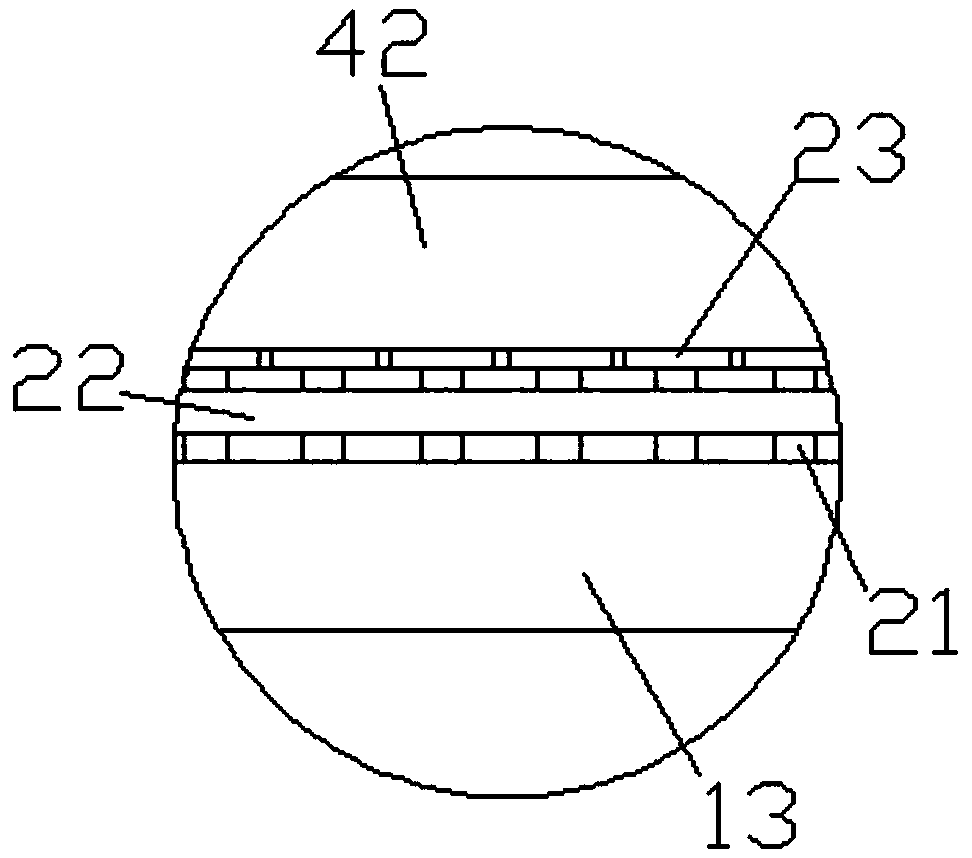

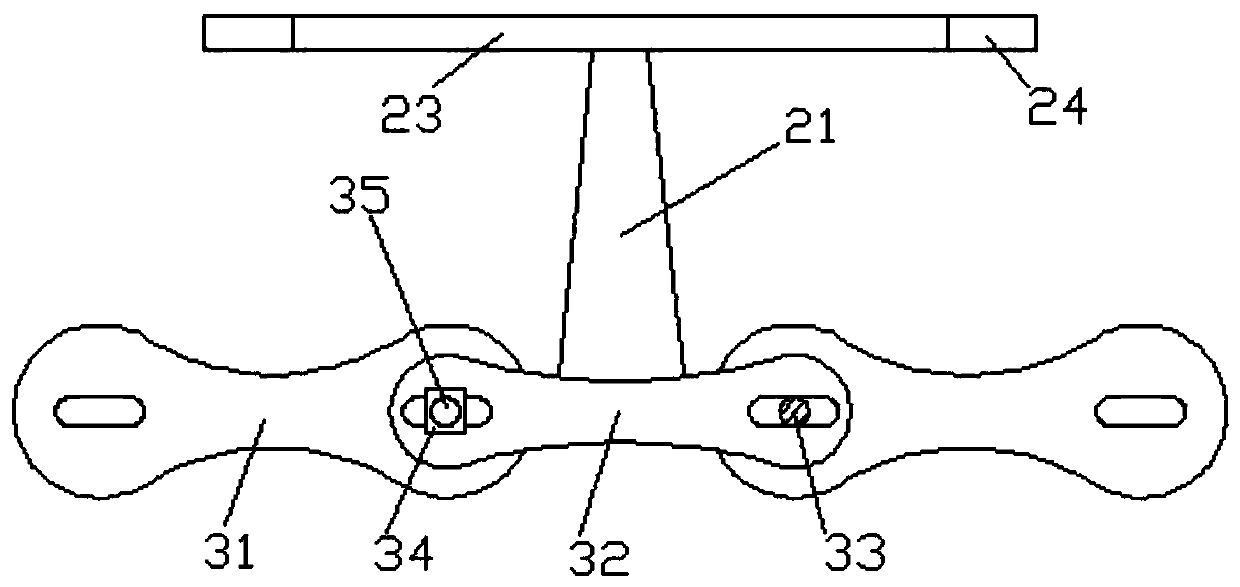

[0022] combine figure 1 , figure 2 Shown; A kind of conveying steering crawler, comprising, device bracket 1, driving motor 2 also include:

[0023] The toothed disc 12 is provided with two groups, which are respectively fixedly installed on the two ends of the upper part of the device bracket 1 through the fixed shaft 102. The fixed shaft 102 is connected to the rotating shaft of the drive motor 2 through a hinge, and the two groups of toothed discs 12 are equipped with chains 103;

[0024] There are two groups of pre-assembled racks 13, and the pre-installed racks 13 are fixedly installed on the device bracket 1 between the two groups of toothed discs 12, and the chain 103 is located inside the pre-installed rack 13;

[0025] The two sides of the chain 103 are respectively welded with connecting plates 21, and two sets of support frames 22 are installed on the device bracket 1. The support frames 22 are ring-shaped structures, and the support frames 22 are ringed outside t...

Embodiment 2

[0032] combine figure 1 , figure 2 Shown; A kind of conveying steering crawler, comprising, device bracket 1, driving motor 2 also include:

[0033] The toothed disc 12 is provided with two groups, which are respectively fixedly installed on the two ends of the upper part of the device bracket 1 through the fixed shaft 102. The fixed shaft 102 is connected to the rotating shaft of the drive motor 2 through a hinge, and the two groups of toothed discs 12 are equipped with chains 103;

[0034] There are two groups of pre-assembled racks 13, and the pre-installed racks 13 are fixedly installed on the device bracket 1 between the two groups of toothed discs 12, and the chain 103 is located inside the pre-installed rack 13;

[0035] The two sides of the chain 103 are respectively welded with connecting plates 21, and two sets of support frames 22 are installed on the device bracket 1. The support frames 22 are ring-shaped structures, and the support frames 22 are ringed outside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com