Lifting machine suitable for detecting eccentric load value of container and working method thereof

A technology for hoists and containers, applied in the directions of measuring devices, load hoisting elements, transportation and packaging, etc., can solve the problems that the detection methods cannot meet the needs of the operation, affect the efficiency of railway transportation, and cannot detect the eccentric load, etc. Direct processing, fast measurement, labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

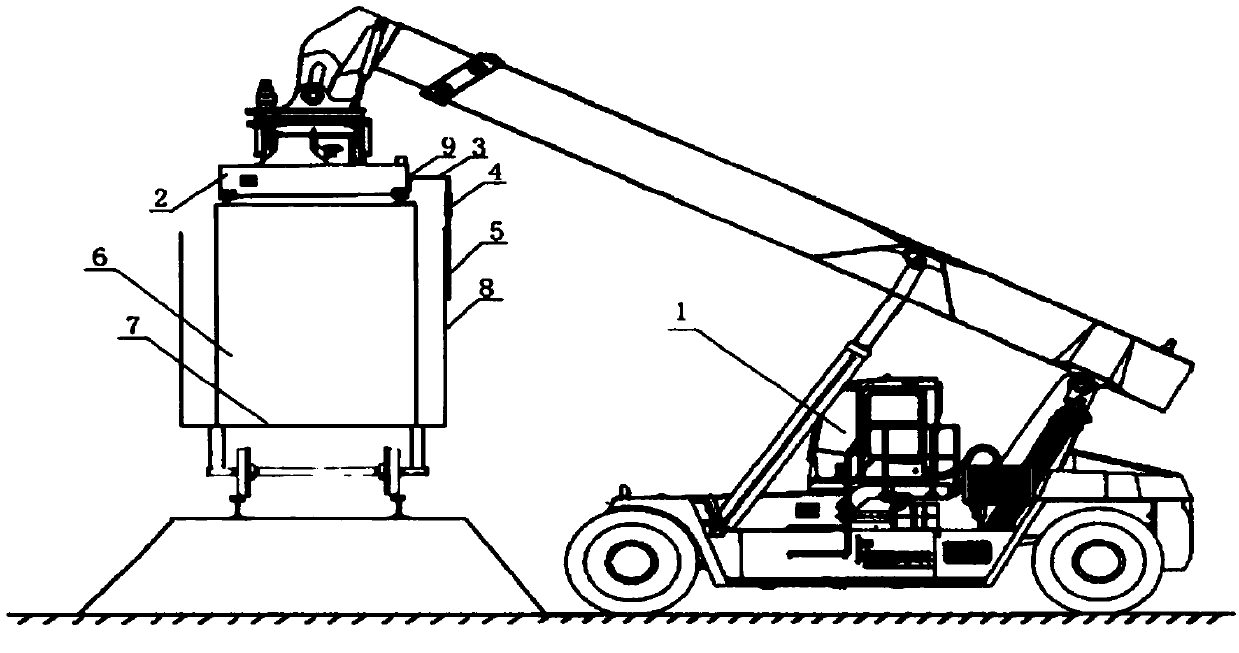

[0058] figure 1 It is a structural schematic diagram of a hoist equipped with a container overload and unbalanced load detection system device according to the present invention.

[0059] see figure 1 , during the container 6 loading process, the container loading position utilizes the positioning vertical bar 4 on the spreader beam 2 of the reach stacker 1, and the contact distance positioning with the open car compartment plate 8 outer wall of the open car 7 of the railway. Before the loading operation, insert the positioning rod fixing pins 9 on the first and second positioning rod cross bars into the pin holes at both ends of the spreader beam 2 of the reach stacker 1; then insert the locks at the four corners of the basic beam Align the lock holes on the top four corners of the container 6 to be shipped and lock them, and after lifting to a certain height, adjust the vehicle to figure 1 The position and angle shown are facing the gondola car 7 parked on the railway line...

Embodiment 2

[0090] On the basis of embodiment 1, this embodiment 2 provides a working method of the hoist.

[0091] The hoisting machine includes: a spreader beam, wherein

[0092] The spreader beam is provided with a detection device for collecting container eccentric load data,

[0093] The detection device is connected with a computer terminal;

[0094] The computer terminal is adapted to calculate the partial load value of the container currently being lifted by the spreader beam according to the partial load data of the container.

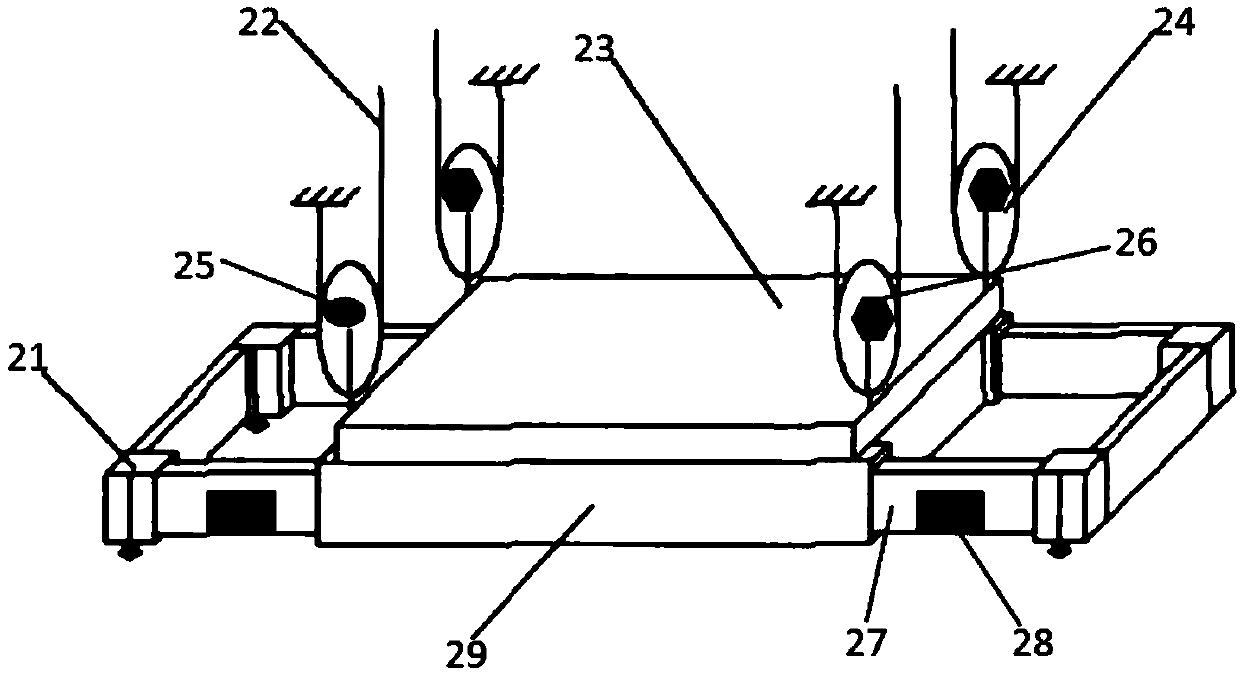

[0095]Further, the spreader beam includes: a telescopic spreader in the middle, a spreader upper frame located at the upper end of the telescopic spreader, pulley blocks distributed at the four corners of the spreader upper frame, and each pulley block corresponds to a lifting wire rope to be fixed to the lifting frame. and the telescopic spreader is respectively connected to four turnlock boxes through corresponding fixed rods; and the detection device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com