Method of continuously extracting procyanidine of seabuckthorn seeds efficiently with high pressure difference at room temperature

A high-efficiency high-pressure-difference, proanthocyanidin technology, applied in climate sustainability, bulk chemical production, energy-saving heating/cooling, etc., to achieve the effects of low production cost, strong industrialization competitiveness, and high energy-saving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

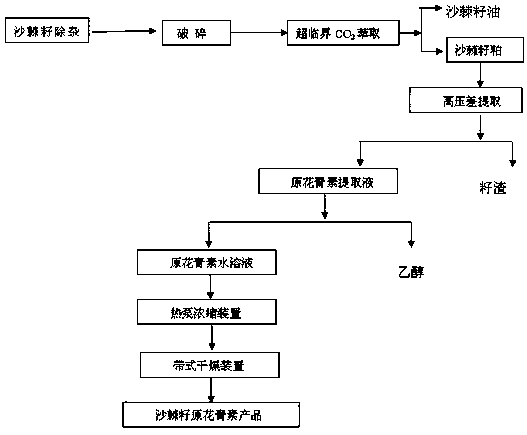

Image

Examples

Embodiment 1

[0022] Embodiment 1: A method for extracting proanthocyanidins from seabuckthorn seeds with high efficiency and high pressure difference at room temperature, comprising the following steps:

[0023] 1) Weigh the supercritical CO 2 After extracting seabuckthorn oil, 5kg of seabuckthorn seed meal was crushed to 50-80 mesh coarse powder, soaked in 50kg of 40% ethanol for 0.5 hours, extracted once at a pressure of 22Mpa using a high pressure differential device, and filtered with a 300 mesh filter cloth to obtain a filtrate of 38kg.

[0024] 2) Use low temperature (20-25°C) negative pressure (-0.098Mpa) heat pump concentration device to recover ethanol from 38kg of extract and concentrate the extract into 1.62kg of proanthocyanidin extract.

[0025] 3) Dry 1.62kg of proanthocyanidin extract with low temperature (25-30°C) negative pressure (-0.098Mpa) belt drying device to obtain 0.78kg of seabuckthorn seed proanthocyanidin extract powder with a proanthocyanidin content of 48.5%. ...

Embodiment 2

[0026] Embodiment 2: A method for extracting proanthocyanidins from seabuckthorn seeds with high efficiency and high pressure difference at room temperature, comprising the following steps:

[0027] 1) Weigh the supercritical CO 2 After extracting seabuckthorn oil, 10kg of seabuckthorn seed meal was crushed to 50-80 mesh coarse powder, soaked in 150kg of pure water for 0.5 hour, extracted twice under a pressure of 25Mpa using a high pressure differential device, and filtered with a 300 mesh filter cloth to obtain 125kg of filtrate.

[0028] 2) Concentrate 125kg of the extract into 3.5kg of proanthocyanidin extract using a low temperature (30°C) negative pressure (-0.098Mpa) heat pump concentration device.

[0029] 3) Dry 3.5kg of proanthocyanidin extract with low temperature (30°C) negative pressure (-0.098Mpa) belt drying device to obtain 1.60kg of seabuckthorn seed proanthocyanidin extract powder, with a proanthocyanidin content of 40.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com