Electromagnetic valve

A solenoid valve and valve needle technology, applied in the field of solenoid valves, can solve problems such as different opening times, fuel injection quantity scattering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

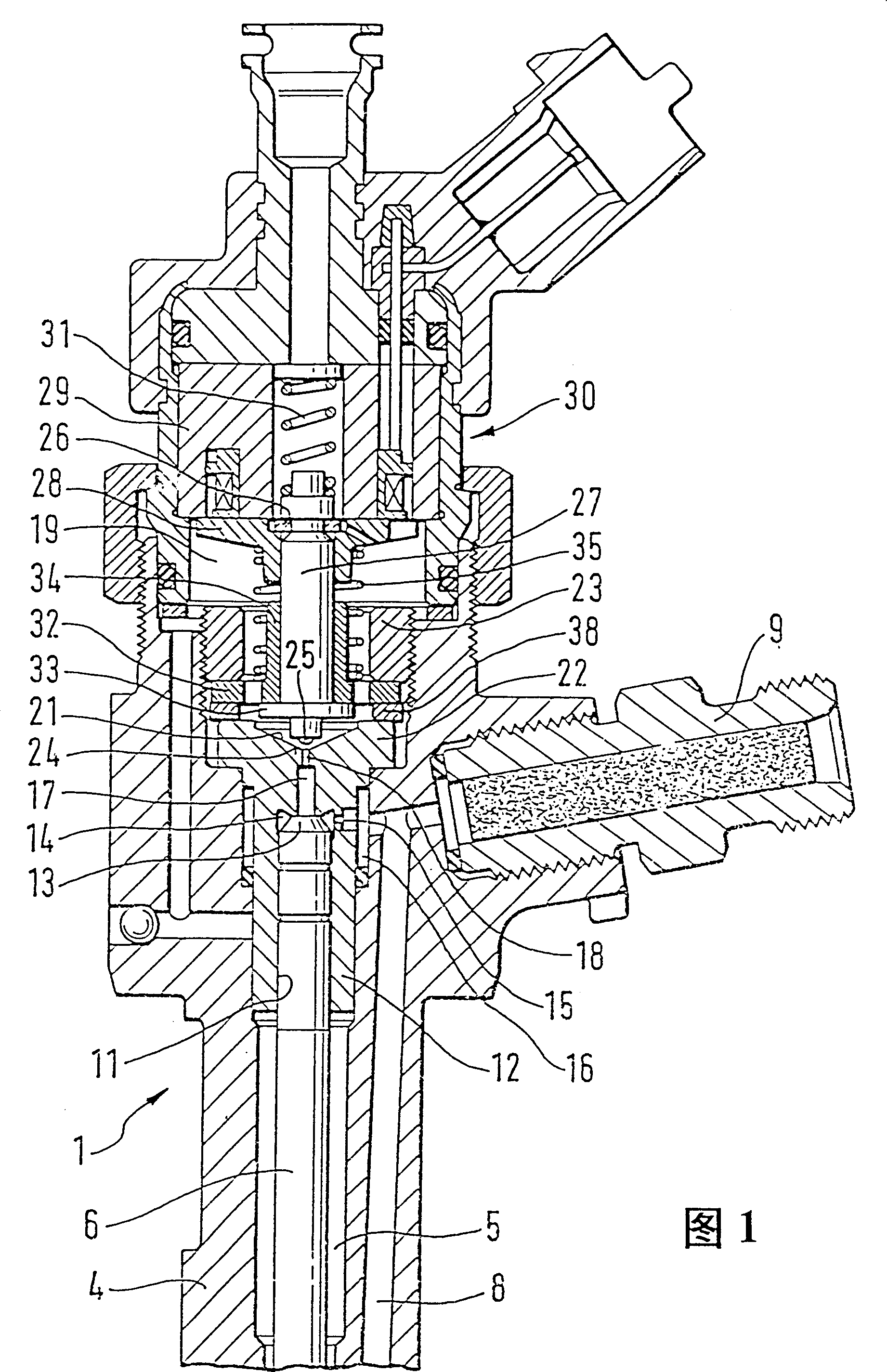

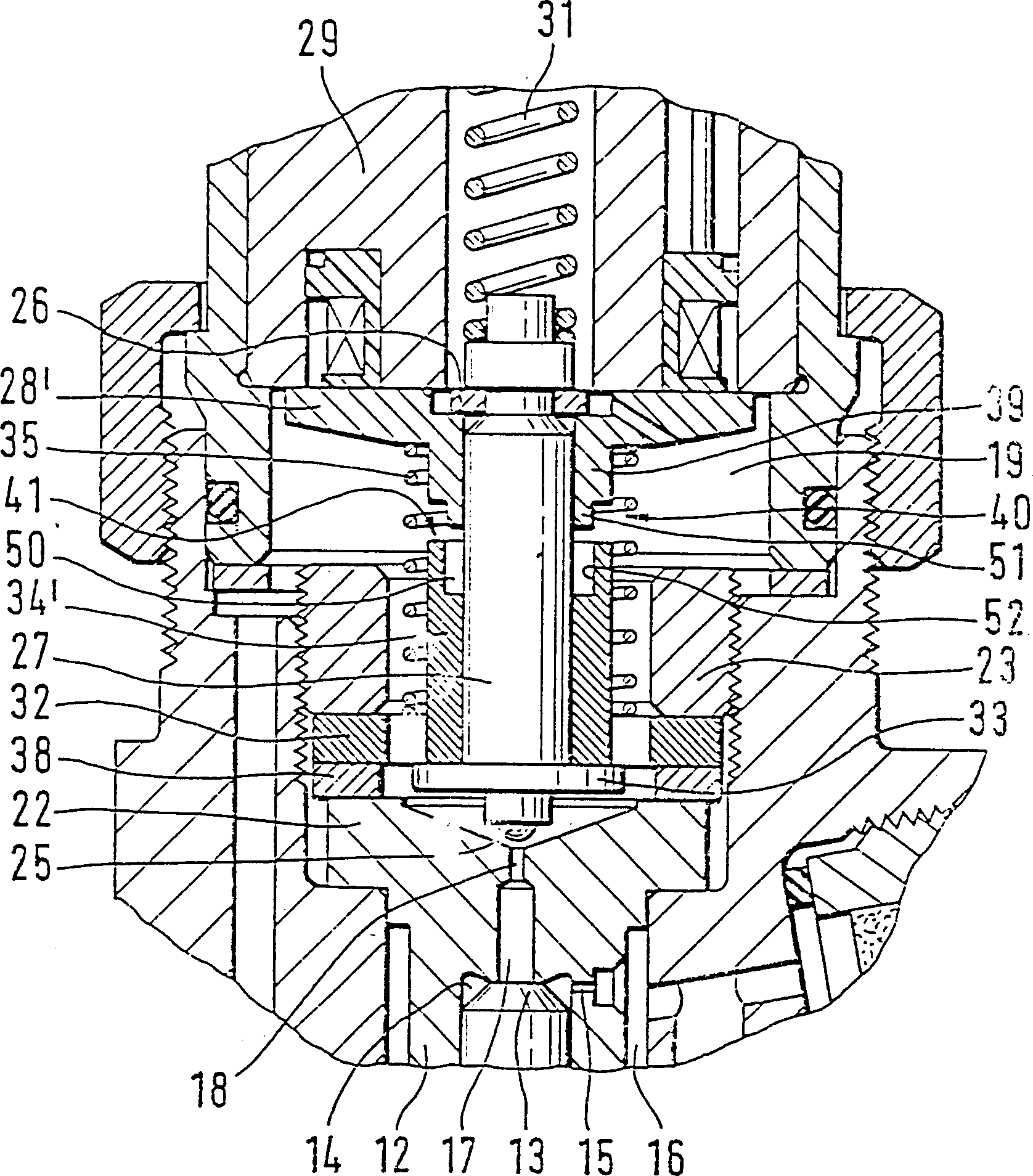

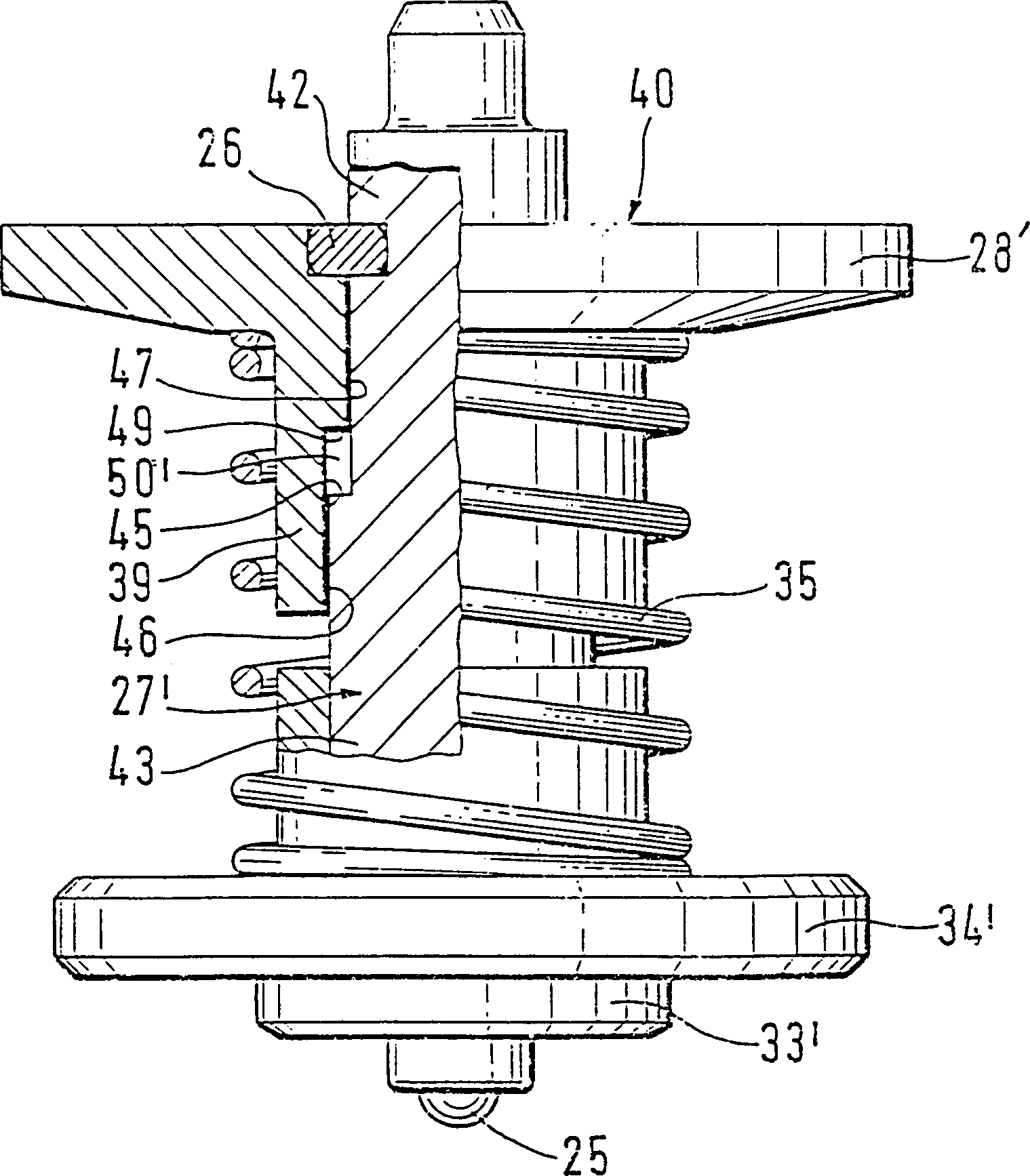

[0012] FIG. 1 shows a partial sectional view of an electronically controlled fuel injector 1 , as is known from the above-mentioned prior art. This fuel injection valve is used for this fuel injection equipment. It is equipped with a high-pressure fuel reservoir, and a high-pressure fuel delivery pump continuously supplies high-pressure fuel to the high-pressure fuel reservoir, and from here the fuel under fuel injection pressure passes through various electric circuits. The controlled fuel injection valve feeds the internal combustion engine. The fuel injection valve 1 shown in part and in section has a fuel injection valve housing 4 with a longitudinal bore 5 in which a valve piston 6 is located, which acts at one end without continuing In the shown valve needle, the valve needle again cooperates with the injection opening of the fuel injection valve in a known manner, for example as described in the aforementioned EP0690223. Here, the valve piston 6 is used to actuate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com