A method for improving breakdown field strength of polypropylene film based on benzil

A polypropylene film and breakdown field strength technology, applied in the parts of fixed capacitors, fixed capacitor dielectrics, etc., can solve the problem of destroying the insulation properties of polypropylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] The method for improving the breakdown field strength of polypropylene film based on benzil comprises the following steps:

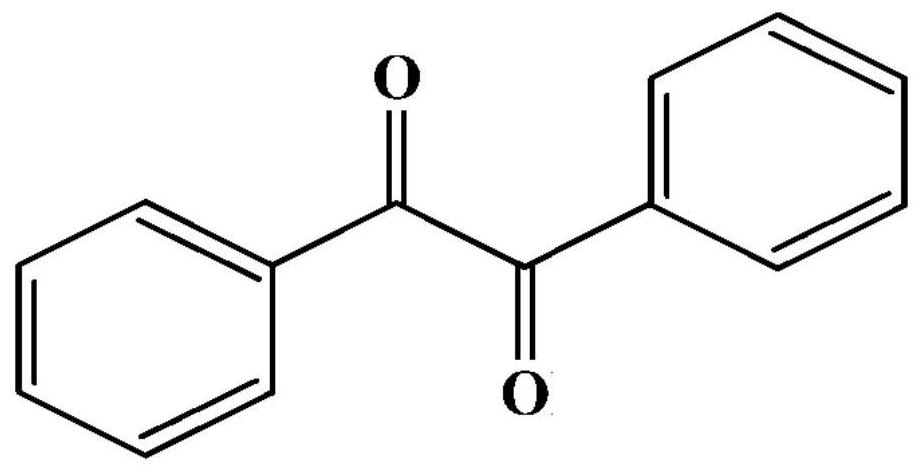

[0019] 1. Combine dry polypropylene particles with benzil (see the chemical formula figure 1 ) according to the mass ratio of 99.5:0.5 was fully mixed in the internal mixer for 10 minutes, the temperature was 180°C, and the rotational speed of the internal mixer was 30r / min to obtain a polypropylene composite material.

[0020] 2. Set up a control group, melt and mix dry polypropylene granules in an internal mixer for 10 minutes at a temperature of 180° C., and a rotational speed of the internal mixer at 30 r / min to obtain a polypropylene material.

[0021] 3. Weigh 5 grams of polypropylene composite material and place it in a flat vulcanizing machine, preheat it at 180°C for 10 minutes to fully melt the polypropylene composite material; ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap