A device for pouring uncooked grains of vinegar

The technology of vinegar grains and mounting rack is applied in the field of vinegar production equipment, which can solve the problems of inability to realize pouring grains, heavy labor for workers, low work efficiency, etc., and achieve the effects of ensuring full contact, improving service life, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

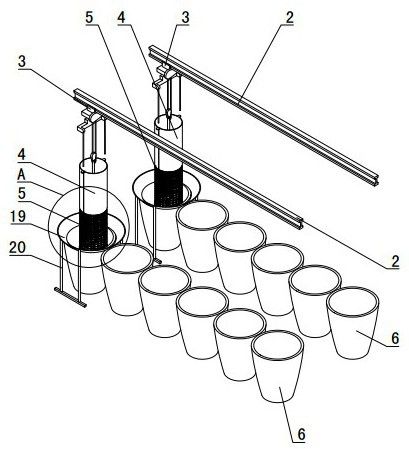

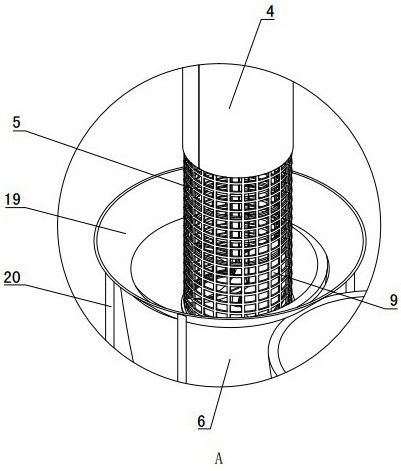

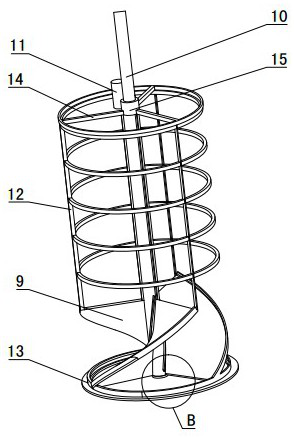

[0033] Such as Figure 1~2 As shown: the translation guide rail is arranged along the arrangement direction of the vinegar vats 6, and a set of vinegar vat automatic pouring device is arranged on the upper side of each row of vinegar vats 6. In this embodiment, the vinegar vat automatic pouring unstrained spirits device also includes a retaining cylinder 19, the retaining cylinder 19 is a cylinder arranged vertically, and the upper and lower ends of the retaining cylinder 19 are all open. The tapered diameter gradually decreases from top to bottom, and the diameter of the lower end of the retaining cylinder 19 is equal to the diameter of the upper opening of the vinegar vat 6, so as to prevent the vinegar grains from falling out of the vinegar vat 6 when extracting and releasing the vinegar grains. A support frame 20 is provided on the underside of the blocking cylinder 19 , and the bottom side of the blocking cylinder 19 is docked with the upper opening of the vinegar cylinde...

Embodiment 2

[0051] Such as Figure 7 Shown: The difference between Embodiment 2 and Embodiment 1 is that there is one translation mechanism, the translation mechanism is installed on the adjustment mechanism and moves horizontally with the adjustment mechanism, and the movement direction of the adjustment mechanism and the movement direction of the translation mechanism are perpendicular to each other in the horizontal plane .

[0052] The adjustment mechanism includes an adjustment guide rail 2 and an adjustment motor. Two adjustment guide rails 2 are arranged in parallel and at intervals. The adjustment guide rails 2 are arranged horizontally. The adjustment guide rail 2 is I-shaped steel. On the adjustment guide rail 2, any one of the adjustment guide rails 2 is provided with an adjustment rack, and the adjustment rack is arranged in parallel with the adjustment guide rail 2. An adjustment gear meshing with the adjustment rack is installed on the output shaft of the adjustment motor, a...

Embodiment 3

[0054] Such as Figure 8 Shown: the difference between embodiment 3 and embodiment 1 is that: the vinegar vat automatic unstrained spirits device includes a feed cylinder 21, a discharge cylinder 23 and a fan 24, the feed cylinder 21 is a vertical cylinder, and the feed cylinder 21 It is a cylinder with both ends open, and the discharge cylinder 23 is a vertically arranged cylinder. The two ends of the discharge cylinder 23 are open, and the discharge cylinder 23 is a cone whose diameter gradually increases from top to bottom. shape, the feeding cylinder 21 and the discharging cylinder 23 are communicated through the connecting pipe 22, the connecting pipe 22 and the upper end of the feeding cylinder 21 are provided with a tapered butt joint whose diameter gradually decreases from bottom to top, and the fan 24 The air outlet communicates with the docking part. During use, the feed cylinder 21 is set in the vinegar vat 6 filled with vinegar grains, the discharge cylinder 23 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com