Automatic constant-temperature electrolyte case

An electrolyte and constant temperature technology, applied in the electrolysis process, electrolysis components, induction heating and other directions, can solve the problems of manual operation, poor constant temperature effect and low efficiency, and achieve the effect of improving work efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

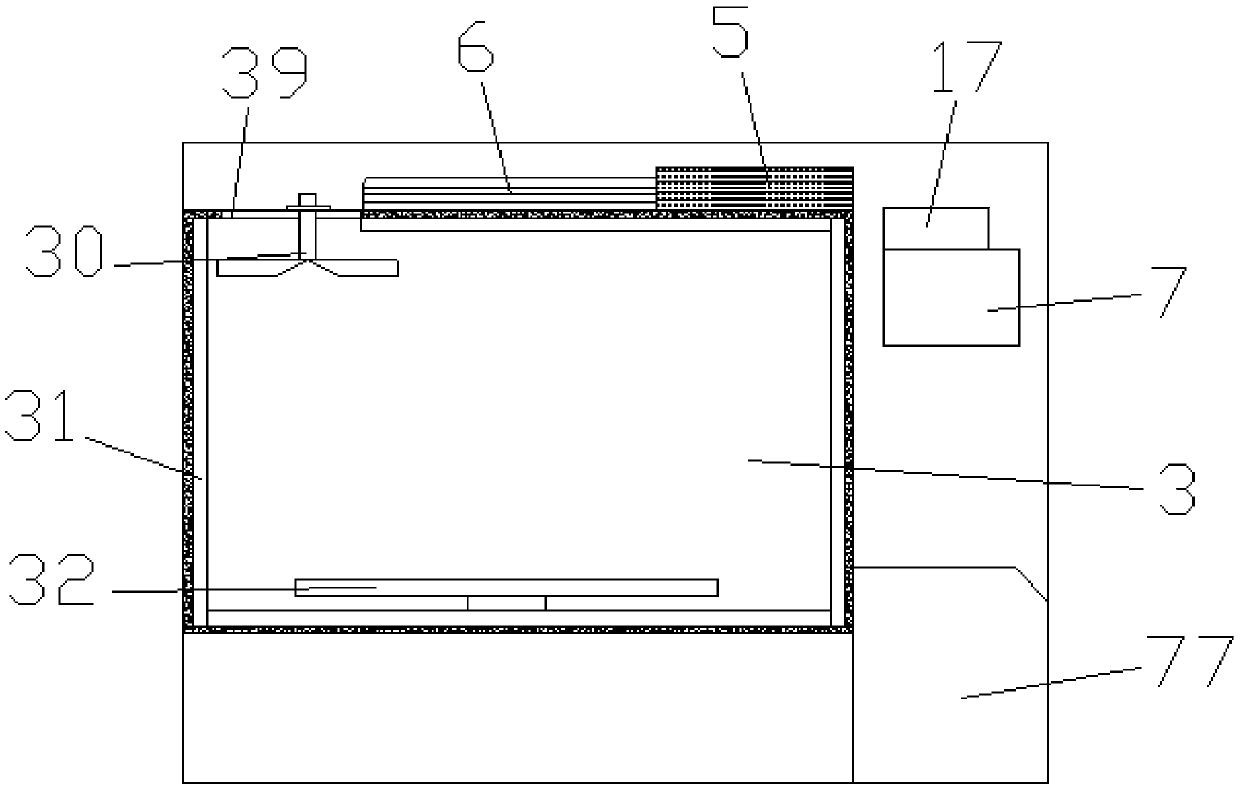

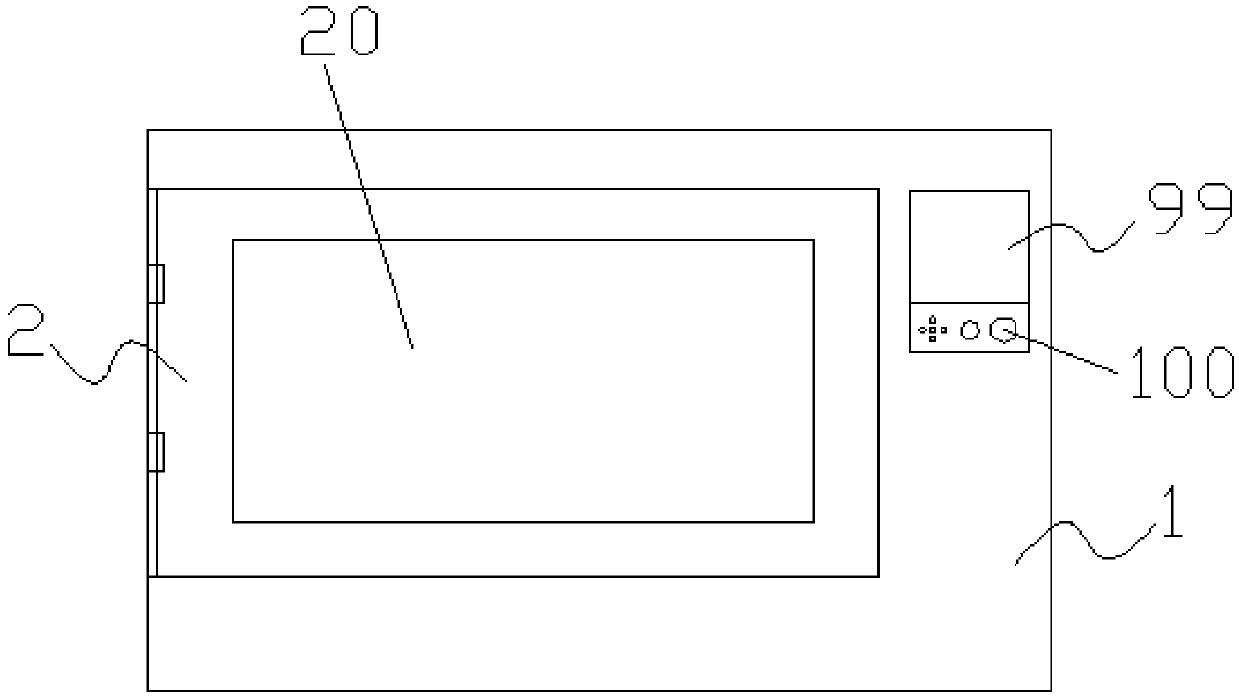

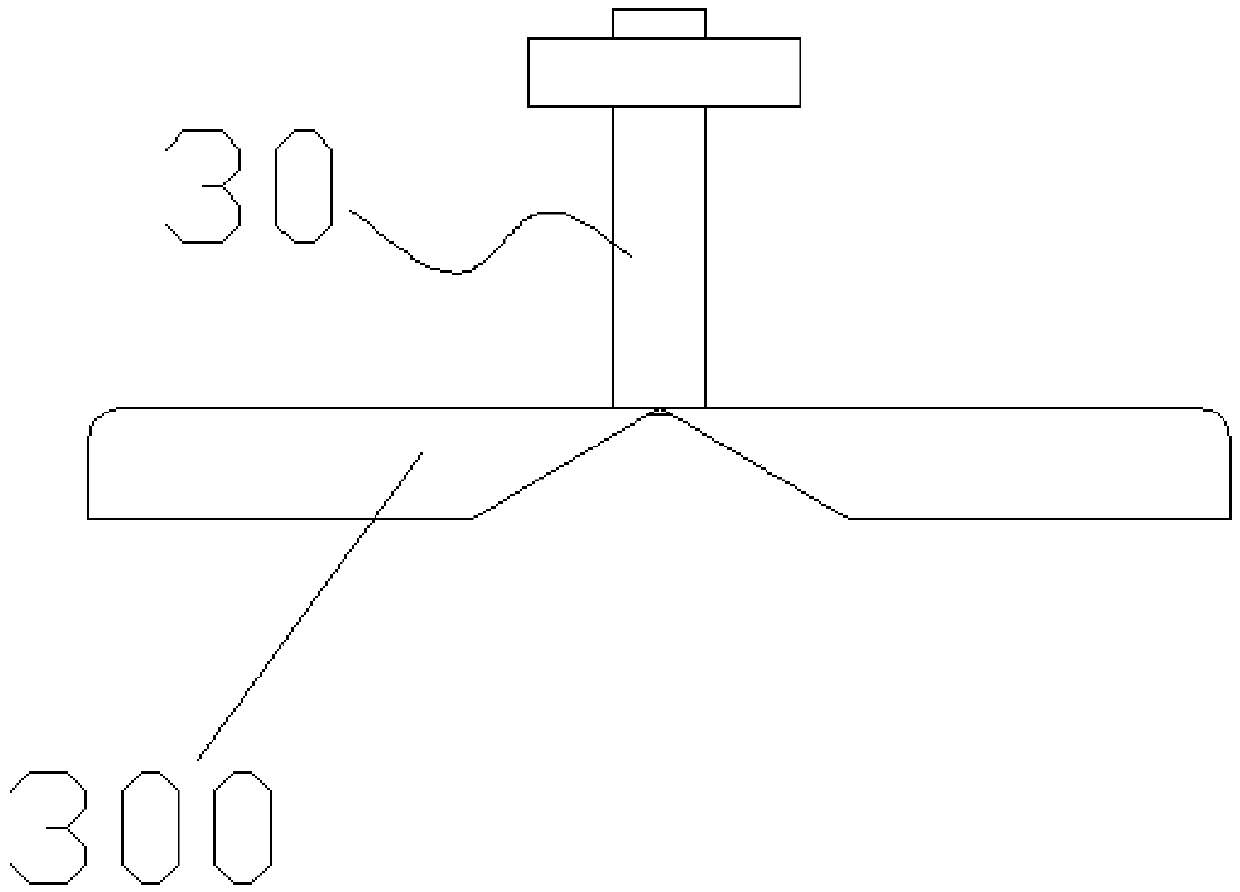

[0014] Combine below Figure 1 to Figure 3 To make a detailed description for the present invention, the electrolyte cabinet capable of automatic constant temperature includes a cabinet shell 1 and a machine cover 2, the front side of the chassis shell 1 is provided with a constant temperature cavity 3, and the constant temperature cavity 3 extends backward to Inside the chassis shell 1, the machine cover 2 is arranged on the front side of the constant temperature chamber 3, and the chassis shell 1 and the machine cover 2 are rotatably connected. The inner bottom is provided with a supporting tray 32, the inner top of the constant temperature chamber 3 is provided with a stirrer 30, and one end of the top of the stirrer 30 is provided with a magnetron 5, and the magnetron 5 is connected to the stirrer 30 through a conduit 6, so An endoscope 20 is arranged in the middle of the machine cover 2, and a temperature controller 17 is arranged on one side of the constant temperature c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com