Central point electrode electrostatic spinning device and spinning method

An electrospinning, center point technology, used in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve problems such as difficulty in achieving roll reception, limiting electrospinning applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in combination with specific embodiments.

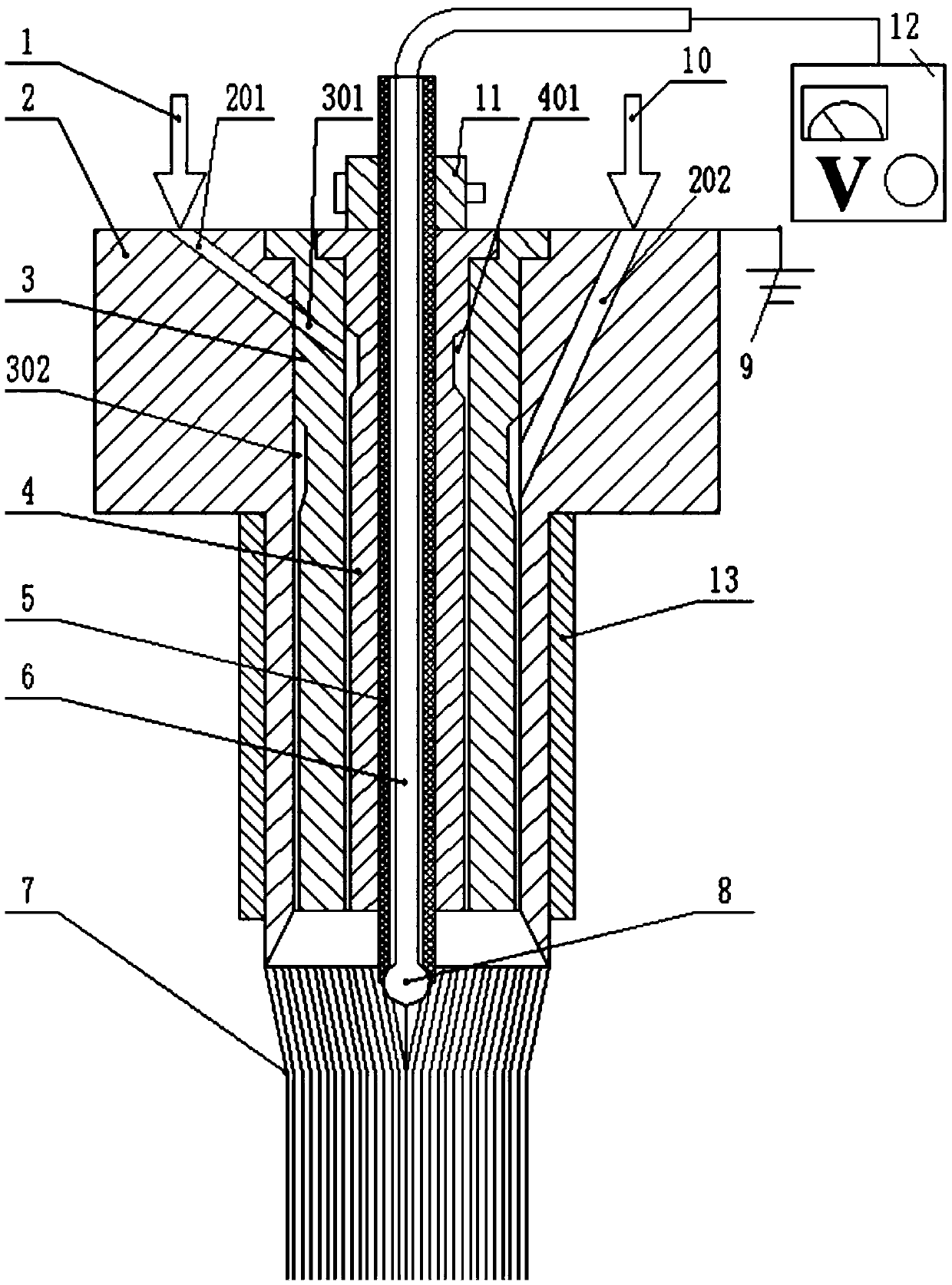

[0009] Electrospinning device of the present invention such as figure 1 As shown, the second sleeve 3 is installed in the first sleeve 2, the upper part of the second sleeve 3 is fixedly connected with the upper part of the first sleeve 2, and the diameter difference between the middle and lower part of the second sleeve 3 and the middle and lower part of the first sleeve 2 An annular flow channel I302 is formed, the third sleeve 4 is inside the second sleeve 3, the upper part of the third sleeve 4 is fixedly connected with the upper part of the second sleeve 3, the middle and lower part of the third sleeve 4 is connected with the middle and lower part of the second sleeve 3 The diameter difference forms the annular flow channel II401, the first sleeve 2 is provided with the direct channel I201 and the direct channel II202, the second sleeve 3 is provided with the direct ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com