Solid-liquid hybrid engine for ground test experiment

A solid-liquid mixing and experimental technology, applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc., can solve the problems of nozzle breakage along the stepped surface, low reliability and safety, and difficulty in optimization. Difficult or even impossible to process, saving research costs, flexible and convenient size adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

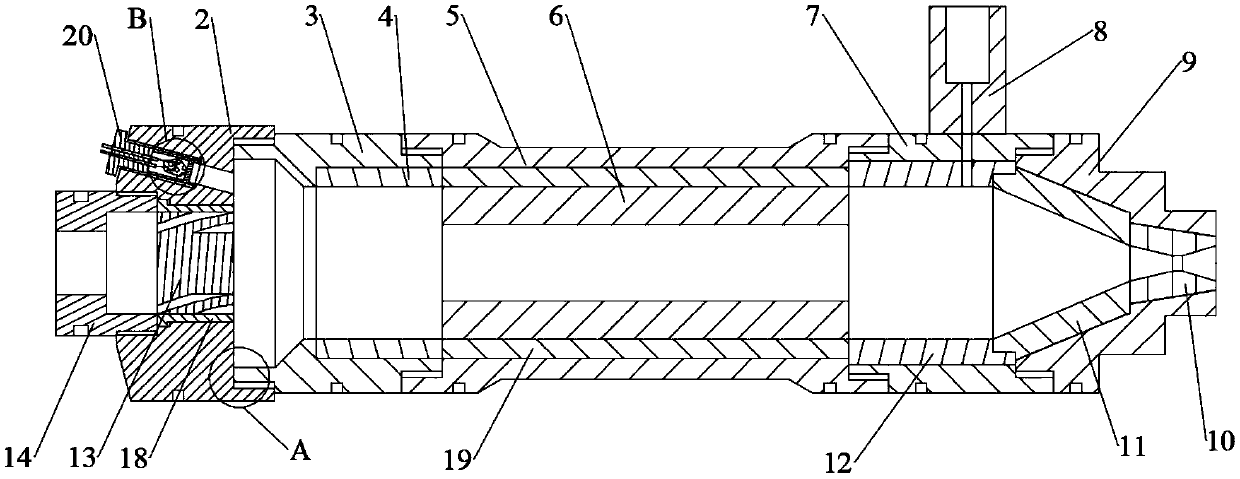

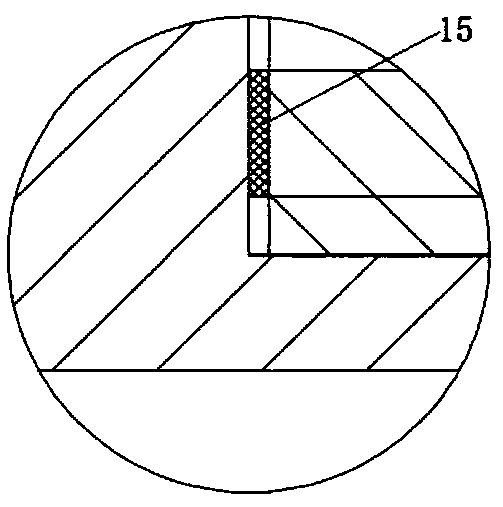

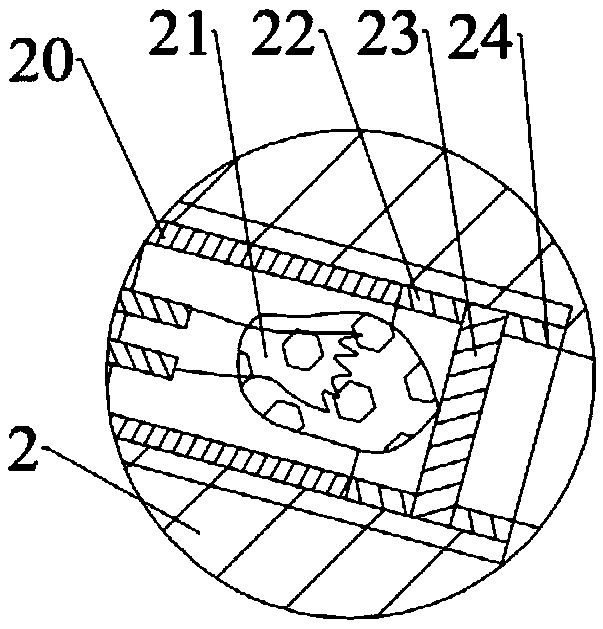

[0054] The solid-liquid hybrid engine for the ground test vehicle comprises a front end cover 2, a pre-combustion chamber housing 3, a combustion chamber housing 5, a supplementary combustion chamber housing 7 and a rear end cover 9, on the outer circumferential surface of the supplementary combustion chamber housing Pressure measuring seat 8 is installed on it. Wherein, one end of the pre-chamber casing and one end of the after-chamber casing are respectively connected to two ends of the combustion chamber casing by threads. The front end cover is screwed to the other end of the pre-combustion chamber shell; the rear end cover is threaded to the other end of the after-combustion chamber shell. The inner end of the injector compression nut 14 is loaded into the central hole of the front end cover 2 . A sealing gasket 15 is placed between the end faces of the auxiliary combustion chamber housing and the combustion chamber housing, as figure 2 shown. The sealing ring is made...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Cone angle | aaaaa | aaaaa |

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com