Burner and heating device with same

A heating device and nozzle technology, applied in the field of machinery, can solve the problems of inability to install tempering devices, uneven preheating temperature, and large waste of natural gas, etc., and achieve the effects of enhanced stability and air tightness, convenient operation, and reasonable air-fuel ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

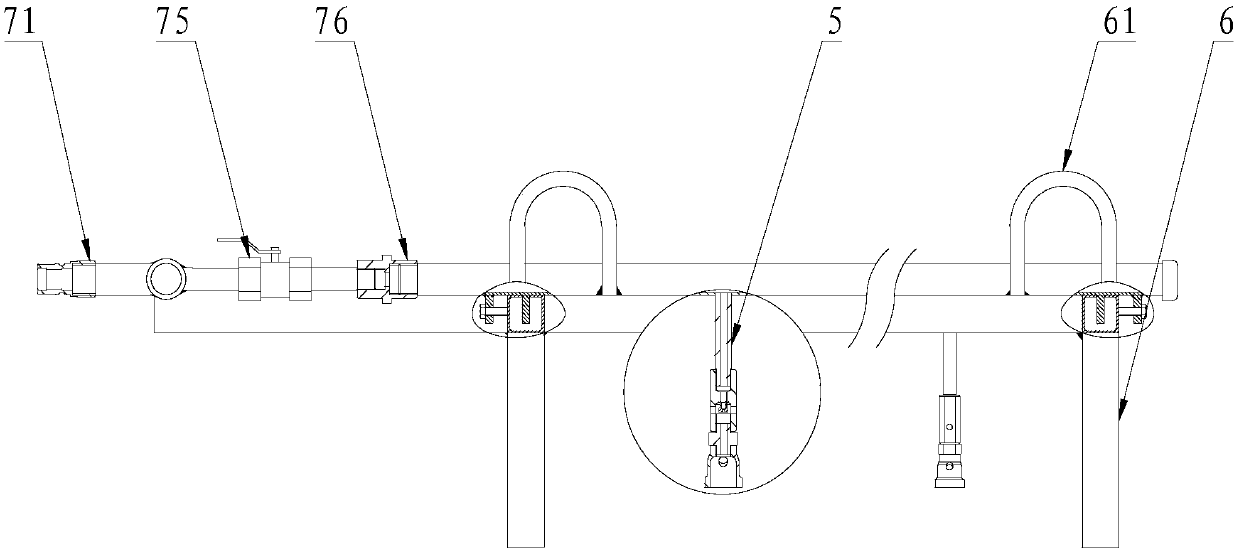

[0022] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

[0023] The most critical idea of the present invention is that a jet nozzle is installed inside the burner shell, which not only makes the burner have the function of preventing backfire, but also can suck in a sufficient amount of air to mix with it when the burner burns, which improves the fire resistance of the flame. Stability, the jet nozzle is only fed with natural gas, and through the first through hole opened on the burner shell, the external air is sucked in by using the pressure difference, which increases the oxygen content.

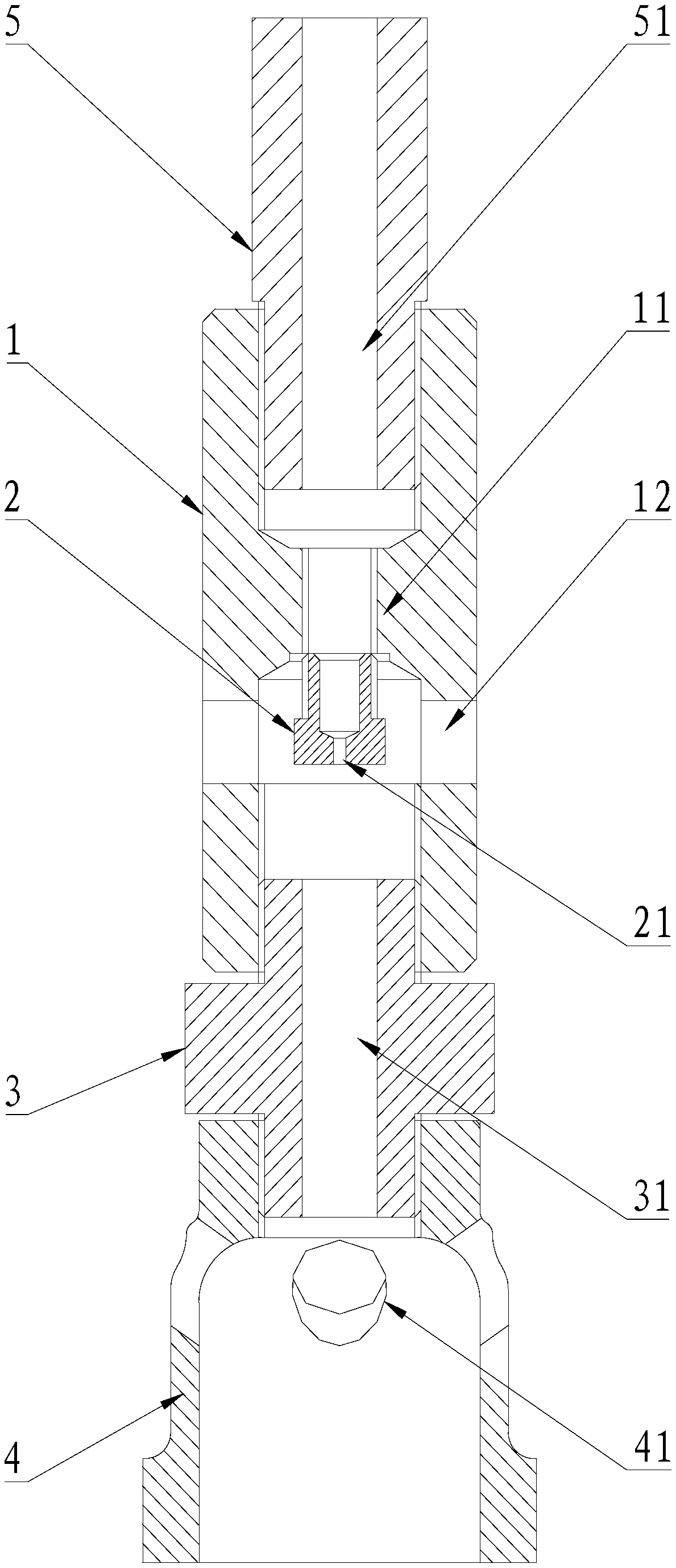

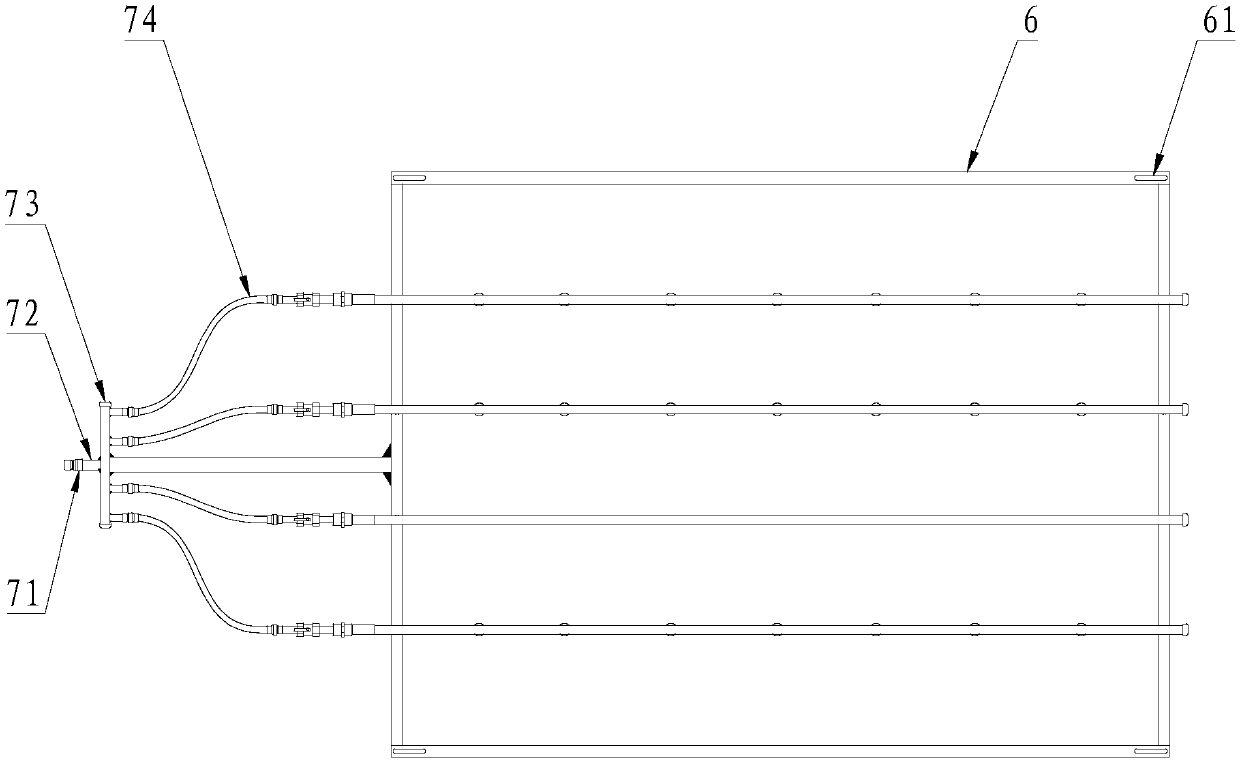

[0024] Please refer to Figure 1 to Figure 5 , a burner, including a burner housing and a jet nozzle, the interior of the burner housing is hollow and has openings at both ends, the inner wall of the burner housing is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com