Fuel cell with function of preventing back-fire

A technology of fuel cells and fuel cell stacks, which is applied in the direction of fuel cells, circuits, electrical components, etc., and can solve problems such as tempering and fuel explosion of hydrogen storage bottles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

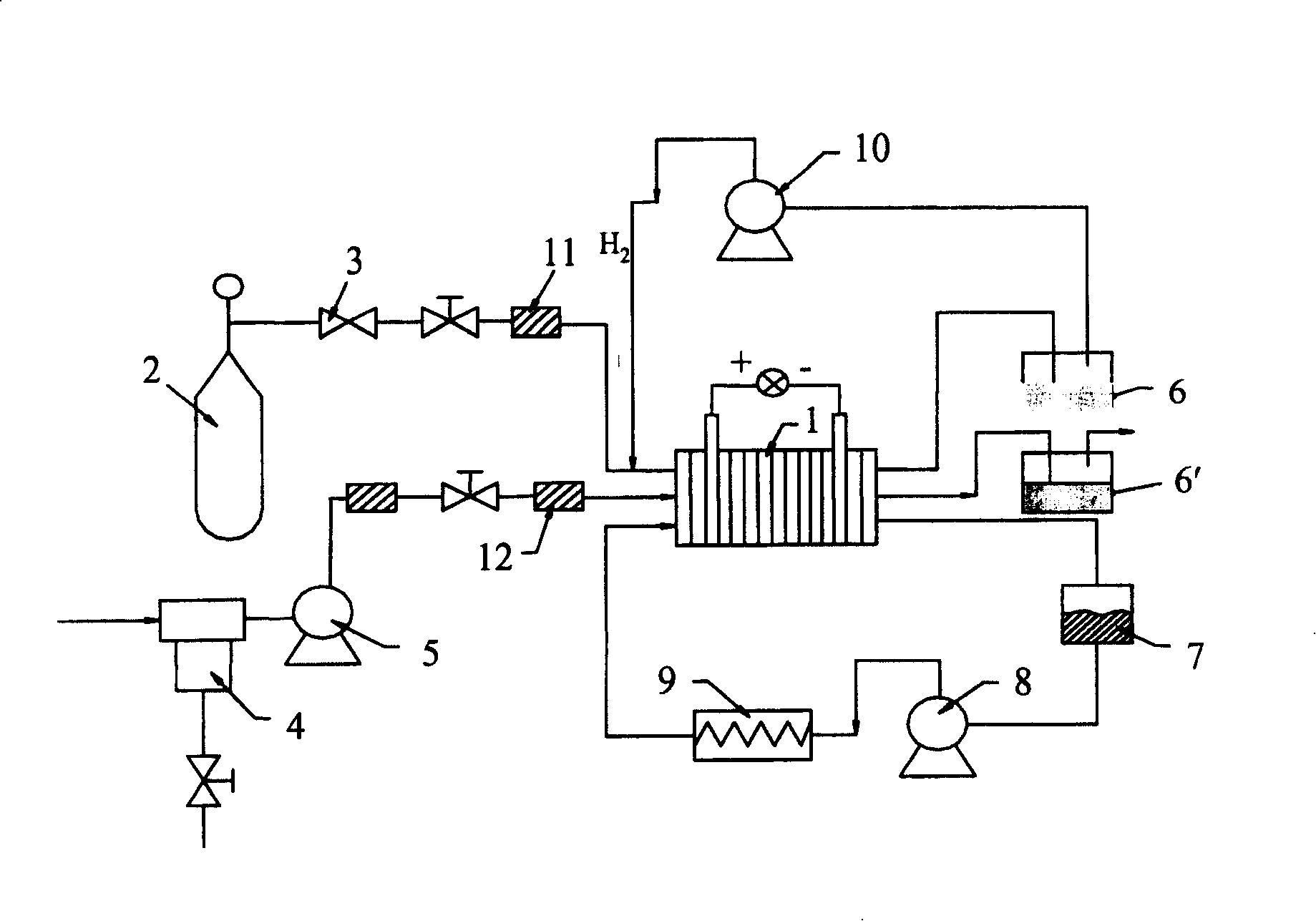

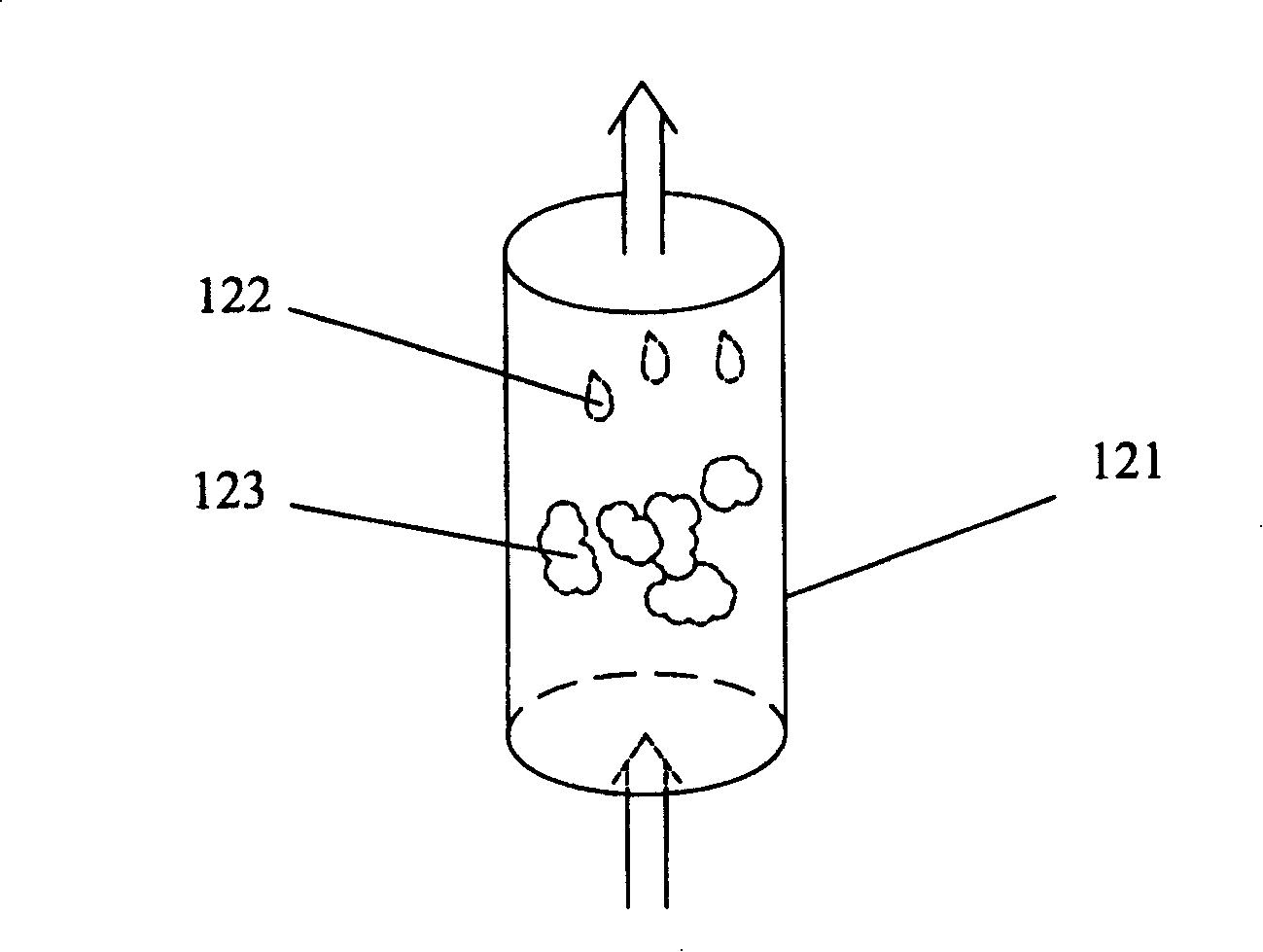

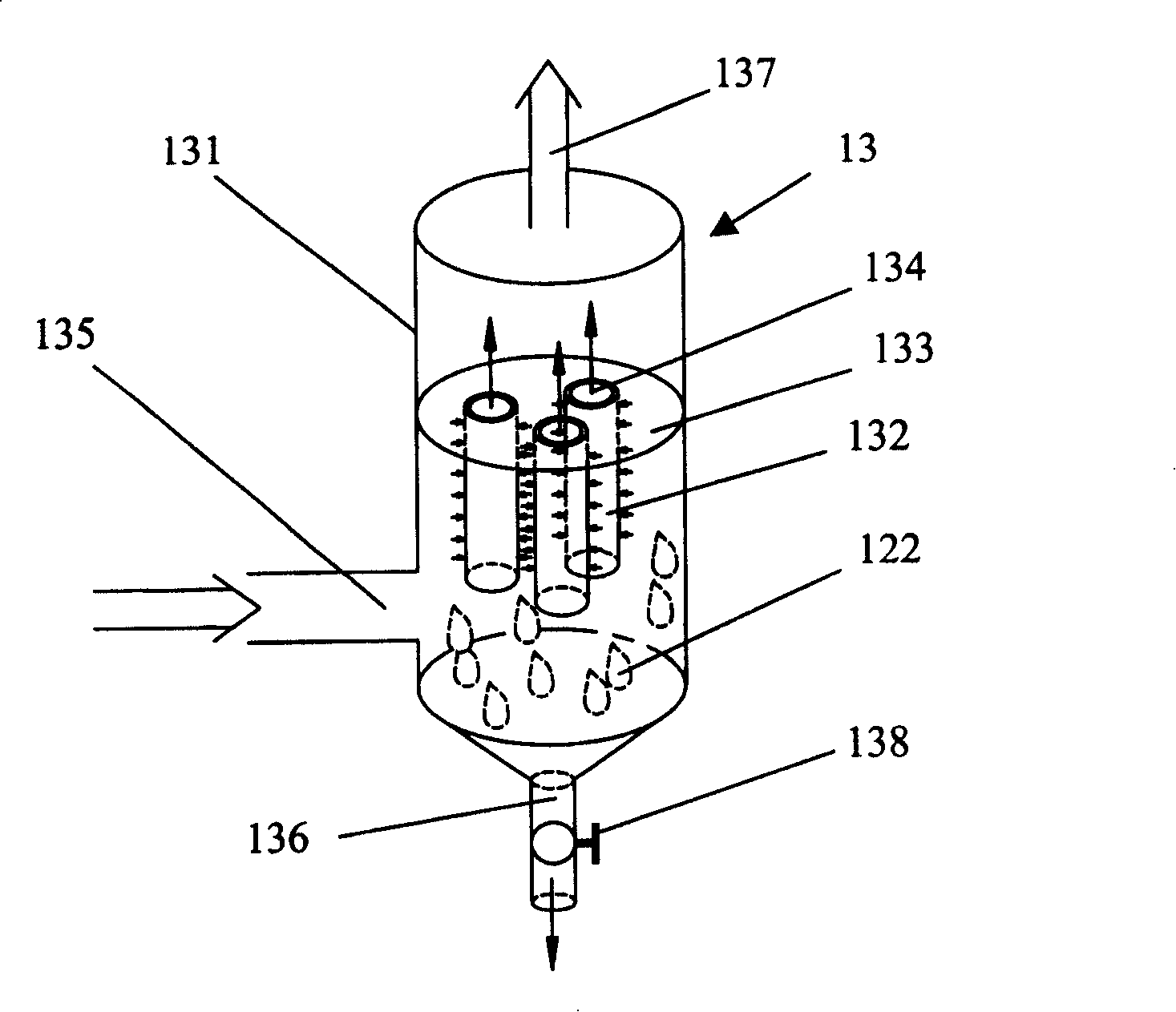

[0029] like image 3 As shown, a fuel cell with anti-backfire function includes a fuel cell stack 1, a hydrogen storage device 2, a hydrogen pressure reducing valve 3, an air filter device 4, an air compression supply device 5, and a hydrogen water-steam separation stack Device 6, stack air water-steam separator 6', water tank 7, cooling fluid circulation pump 8, radiator 9, hydrogen circulation pump 10, hydrogen humidification device 11, air humidification device 12, humidification hydrogen water- Steam separator 13, the described humidification hydrogen water-steam separator comprises stainless steel housing 131, is provided with three permeable (hydrogen) gas impermeable porous stainless steel tubes 132 and a stainless steel separator 133 in this housing 131 , the housing 131 is cylindrical.

[0030] The humidified hydrogen water-steam separator 13 is vertically arranged, and the partition plate 133 is arranged on the middle and upper part of the inner cavity of the separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com