Swirl combustor head with variable air inlet section

A combustion chamber and head technology, which is applied in the low-pollution combustion field of aero-engines, can solve the problems of low NOx generation rate, etc., and achieve the effect of high combustion efficiency and emission reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described now in conjunction with accompanying drawing:

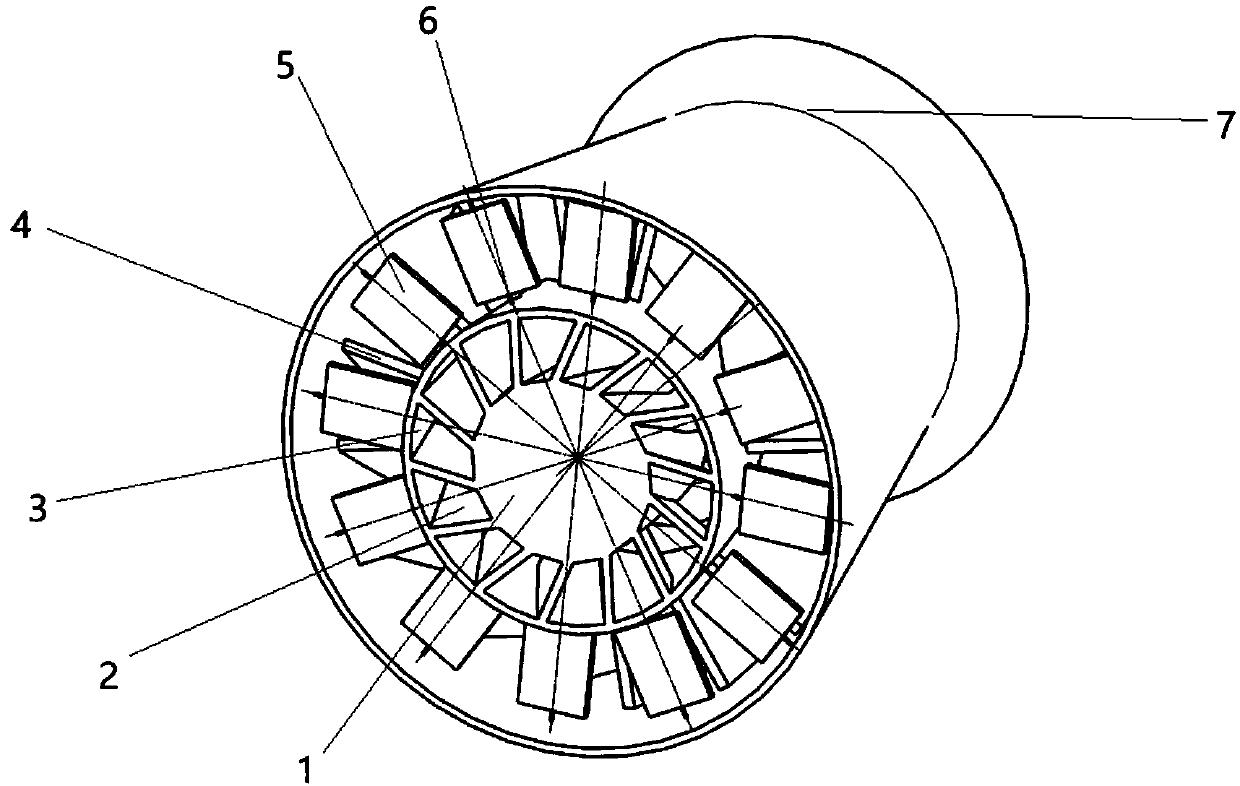

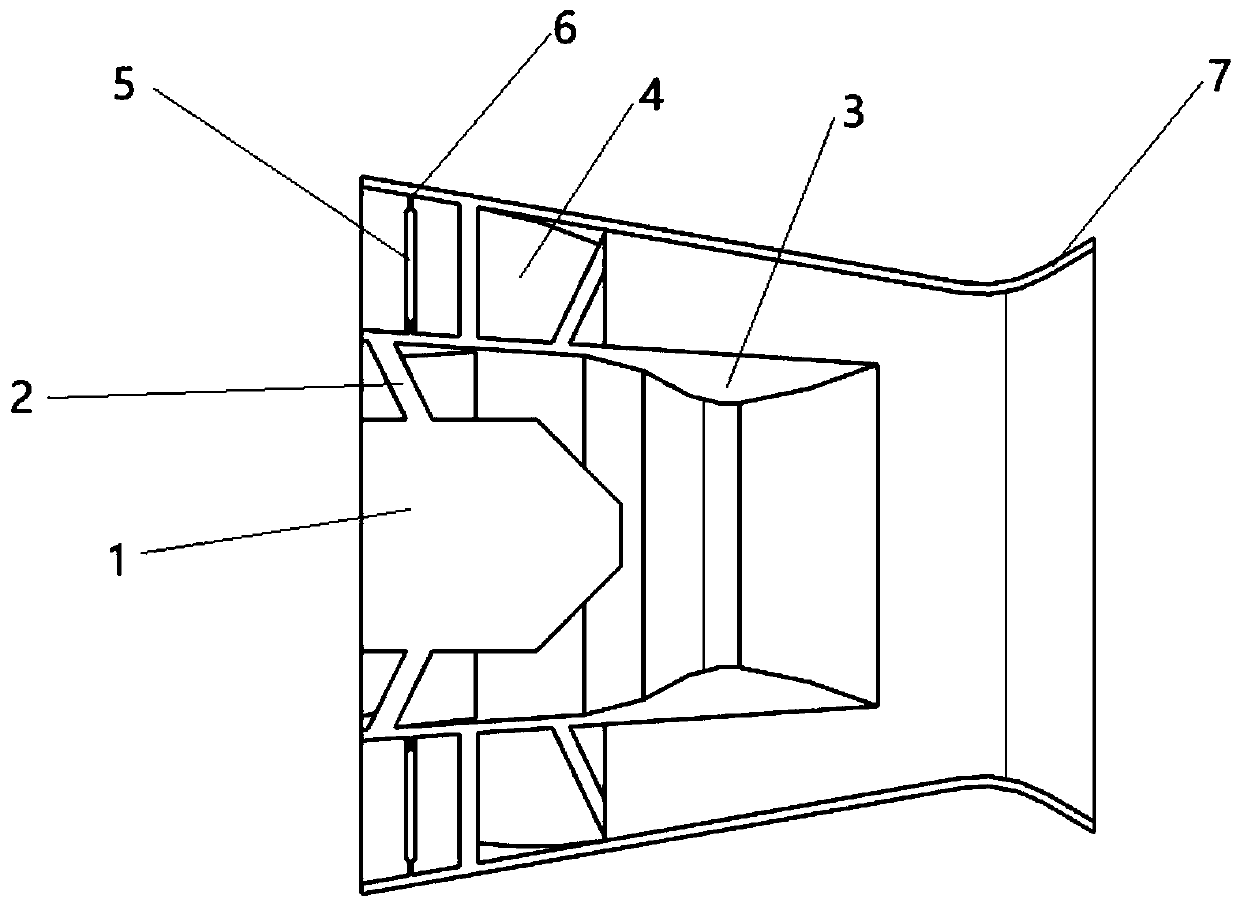

[0026] combine figure 1 , the invention provides a swirl combustor head with variable inlet cross-section.

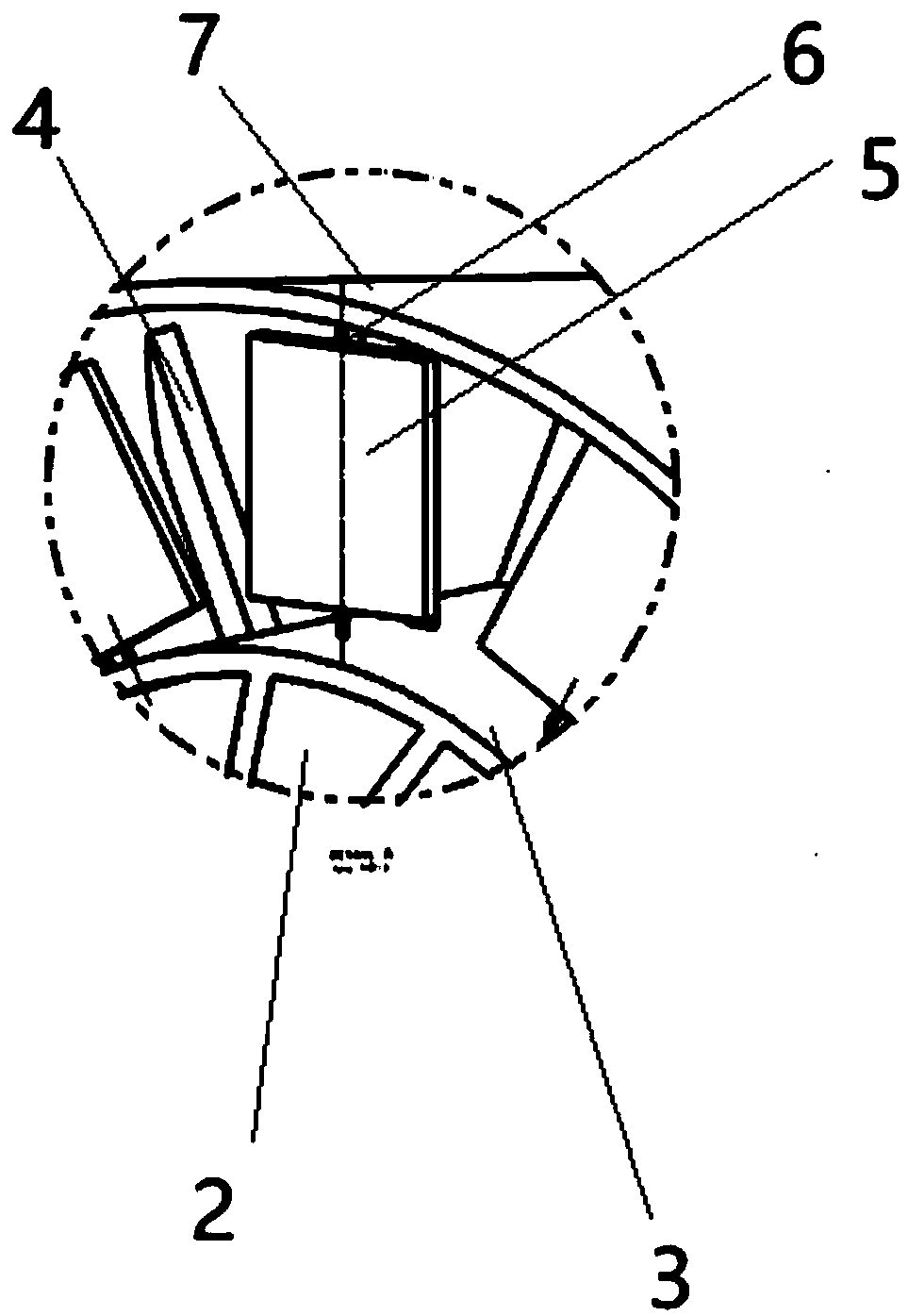

[0027] Specific process: In low operating conditions such as take-off and high-altitude re-ignition, the guide vanes maintain the maximum windward area ( Figure 4 ), the duty-level nozzles are supplied with fuel until the start-up process is completed, and the main fuel-level nozzles do not supply fuel or supply a small amount of fuel. In this case, the on-duty air forms a recirculation zone. At this time, only the on-duty air participates in the combustion in the main combustion zone. In the design state, the oil-gas ratio far exceeds the chemical proper ratio, forming a fuel-rich combustion state. In this state, the ignition is easier and the lean flameout limit is wider, which effectively improves the ignition and lean flameout performance of the combustion chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com