External wall thermal insulation material and preparation method thereof

A technology of external wall insulation and raw materials, applied in the field of external wall insulation materials and its preparation, can solve the problems of high cost and poor mechanical properties of rigid foam plastics, and achieve enhanced fire performance, good flame retardant effect, good flame retardant and smoke suppression effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

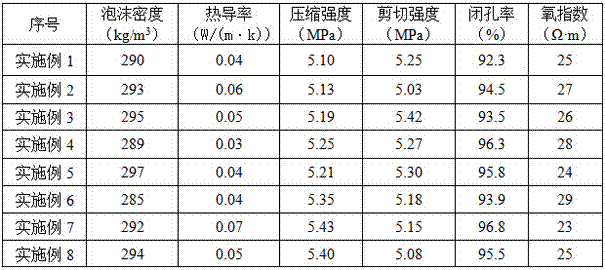

Examples

preparation example Construction

[0043] The present invention also provides a preparation method of the above-mentioned external wall thermal insulation material, comprising the following steps:

[0044] (1) Put 30~35 parts of flame retardant and 25~30 parts of smoke suppressant into 65~75 parts of polyether polyol, stir and mix evenly at a speed of 3000r / min, then ultrasonically treat for 1.5~2h;

[0045] (2) Add 80~90 parts of diphenylmethane diisocyanate, 1~5 parts of reaction catalyst, 8~15 parts of crosslinking catalyst to the mixture obtained in step (1), stir for 2~5 minutes, and the speed is 3000r / min;

[0046] (3) Add 20-30 parts of straw fiber, 10-15 parts of glass fiber, 20-25 parts of nano-organic montmorillonite, 1-5 parts of coupling agent, 15-25 parts of Deionized water, 1.5~5 parts of foam stabilizer, stirring for 1~3min, the speed is 3000r / min;

[0047] (4) inject the mixture obtained in step (3) into the mold for foaming, expansion and shaping;

[0048] (5) Curing the foam prepared in step...

Embodiment 1

[0054] An external wall insulation material, comprising the following raw materials in parts by weight: 80 parts of diphenylmethane diisocyanate, 65 parts of polyether polyol, 20 parts of straw fiber, 10 parts of glass fiber, and nano-organic Mongolian with a particle size of 50-75nm 20 parts of soil removal, 30 parts of a mixture of modified expandable graphite and ammonium polyphosphate (the weight ratio of modified expandable graphite: ammonium polyphosphate is 1:1), a mixture of molybdenum trioxide and zinc borate (molybdenum trioxide: The weight ratio of zinc borate is 2:8) 25 parts, 1 part of dibutyltin dilaurate, 8 parts of pentamethyldiethylenetriamine, 1 part of 3-aminopropyltriethoxysilane, 15 parts of deionized water, 1.5 parts of water-soluble silicone oil.

[0055] Among them, the nano-organic montmorillonite is prepared by organically treating the montmorillonite with octadecyl quaternary ammonium salt.

[0056] Wherein, the preparation method of modified expand...

Embodiment 2

[0067] An external wall thermal insulation material, comprising the following raw materials in parts by weight: 82 parts of diphenylmethane diisocyanate, 66 parts of polyether polyol, 21 parts of straw fiber, 11 parts of glass fiber, and nano-organic Mongolian with a particle size of 50-75nm 21 parts of soil removal, a mixture of modified expandable graphite and ammonium polyphosphate (the weight ratio of modified expandable graphite: ammonium polyphosphate is 5.5:4.5), 31 parts, a mixture of molybdenum trioxide and zinc borate (molybdenum trioxide: The weight ratio of zinc borate is 2.5:7.5) 26 parts, 2 parts of dibutyltin dilaurate, 9 parts of dimethylhexylamine, 2 parts of γ-methacryloxypropyl trimethoxysilane, 16 parts of deionized water Parts, 2 parts of water-soluble silicone oil.

[0068] Among them, the nano-organic montmorillonite is prepared by organically treating the montmorillonite with octadecyl quaternary ammonium salt.

[0069] The preparation method of the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com